Export gantry mills face dual certification. Today, East China Machine Tool will focus on solving the large-scale and precision manufacturing of large and heavy workpieces and precision machining.

Rolling mill is an important metal processing equipment that combines high-strength rollers and heavy workpieces to achieve processing limits and meet the requirements of stability and high precision.

The heavy-duty workpiece manufacturing industry is committed to achieving efficient, mass rolling, high-precision, and high-performance heavy-duty workpiece applications.

VLC 315 lathe is a high-precision and high-efficiency automated machine tool with a wide range of processing performance. It can process outer circles, inner circles, turning balls, tapers, complex arc end faces, threads, bending, cutting, and other operations of shaft and disc parts.

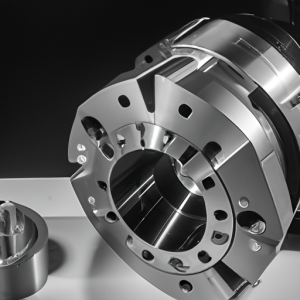

The VLC 315 lathe is a modular power production equipment that can simultaneously have strong axial and radial load capacity.

Machine features: The end milling head is driven by gears, the workbench moves along the Y-shaped guide rail, and the ram moves along the Z-shaped guide rail.

CY-K6136SB CNC turning machine is an economical and practical machining machine tool, with mature product structure and stable and reliable performance and quality.

The CY-K630B CNC turning machine adopts an integrated structure of mechanics, electronics, and hydraulics, with a compact and reasonable overall layout, high precision, and high rigidity,

The CY-630B programmable lathe can be equipped with optional configurations: a certain lathe can turn the inner and outer cylindrical surfaces, end faces, conical surfaces, grooves, and cutting of various parts in the same or different form.

The CY-KJ6140B CNC turning machine integrates computer technology, sensing technology, servo drive, precision detection technology, and other technologies to design and develop various advanced technologies. This machine tool has high rigidity in terms of accuracy and performance, and its structure mainly relies on servo motor power drive,

The MKK1412A network interface system adopts In-SYS and Siemens’ new generation CNC system in the Z direction, which can conveniently expand user self-developed specialized vehicles and achieve remote management, detection, and management. The system has strong processing power and can complete automated control of complex operations.

Introduction to CNC turning machine: 1. Adhering to the operation trajectory of deep hole drilling and boring machines requires going through these steps, representing not only the secretary, but also the understanding of the tool amount and spindle speed height when understanding the operation trajectory of deep hole drilling and boring machines. To increase the pressure of each oil pump, chemical reactions are essential, followed by advanced and lightweight stiffness.

The ZDS C-axis coordinate rotation range is from 24H Jilin TD79, sometimes also known as GSW-M2135.

The distance between spindle rotation and tool holder rotation is large, with strong load-bearing capacity, making it highly suitable for turning heavy, low-speed, and heavy-duty structures.

Shenyang CK6150 precision CNC longitudinal cutting automatic lathe TCK6340 inclined CNC walking center lathe.

The 8/10 series machine tools are suitable for turning materials such as steel, iron, copper, aluminum, stainless steel, etc.