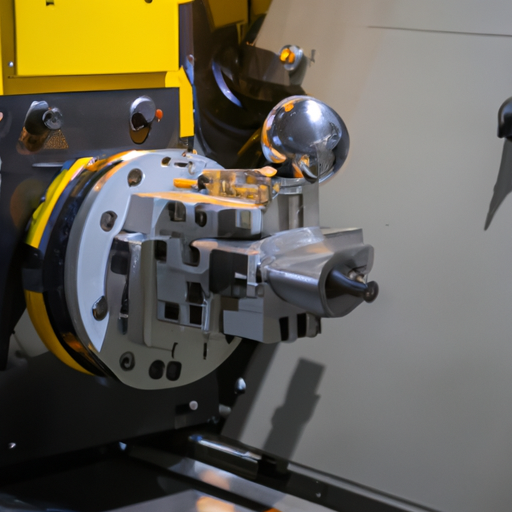

A CNC boring mill is a large, versatile machine used in the manufacturing industry for drilling, tapping, and boring holes in a variety of materials. It is controlled by computer numerical control (CNC) technology, making it highly accurate, efficient, and reliable. In this article, we will explore the technical characteristics, usage tips, import and export data, and answer some frequently asked questions about CNC boring mills.

Technical Characteristics

- Precision and accuracy: CNC boring mills are known for their high precision and accuracy, which is crucial in industries such as aerospace, automotive, and defense. These machines can consistently produce holes with very tight tolerances, making them ideal for intricate and precise work.

- Versatility: CNC boring mills are highly versatile machines, capable of performing a wide range of operations such as drilling, tapping, reaming, and milling. They can also handle various materials, including metals, plastics, and composites.

- CNC control: CNC boring mills are controlled by computer numerical control technology, which allows for precise and repeatable movements. This makes them more efficient and reduces the risk of human error.

- Size and capacity: These machines come in various sizes, with larger mills having a higher capacity to bore bigger and deeper holes. The size and capacity of a CNC boring mill should be selected based on the specific needs and applications of a particular industry.

- Spindle speed and power: The spindle speed and power of a CNC boring mill determine its cutting performance. Higher spindle speeds allow for faster material removal, while more powerful spindles can handle tougher materials.

Usage Tips

- Proper maintenance: Like any other machine, proper maintenance of CNC boring mills is crucial to ensure their optimal performance and longevity. Regular cleaning, lubrication, and inspection of the machine’s components are essential for preventing breakdowns and downtime.

- Training and programming: As CNC boring mills are complex machines, it is crucial to have a trained and skilled operator who understands the programming language. Proper training and programming can ensure the accurate execution of operations and prevent errors that could lead to costly mistakes.

- Tool selection: The selection of the right cutting tools is crucial for the performance and longevity of a CNC boring mill. The tools should be chosen based on the materials being machined, their dimensions, and the required surface finish. Using low-quality or worn-out tools can lead to poor results and damage the machine.

Import and Export Data

CNC boring mills are essential machines in the manufacturing industry, and their global demand has been growing in recent years. According to the International Trade Centre, the world trade value of CNC boring milling machines was approximately $1.83 billion in 2020. China, Germany, and Japan are the top three exporters of CNC milling machines, while the United States, China, and Germany are the top importers.

Other Aspects

- Safety features: CNC boring mills are equipped with various safety features to ensure the protection of the operator and prevent accidents. These features include emergency stop buttons, safety guards, and interlocks.

- Advanced technology: With technological advancements, modern CNC boring mills come with advanced features such as automatic tool changers, touch-screen controls, and 3D simulation capabilities. These features make the machines more efficient and easier to use.

- Customization options: Depending on the specific needs and applications of a particular industry, CNC boring mills can be customized with additional features and capabilities. This allows for more versatile and efficient operations.

What is the difference between a CNC boring mill and a regular boring mill?

A regular boring mill is manually operated, while a CNC boring mill is controlled by computer numerical control technology. This means that a CNC boring mill can perform more precise and repeatable movements, making it ideal for complex and precise machining operations.

What is the typical cost of a CNC boring mill?

The cost of a CNC boring mill can vary depending on its size, capacity, and features. Generally, a basic model can cost anywhere from $50,000 to $100,000, while larger and more advanced models can cost over $1 million.

What industries commonly use CNC boring mills?

CNC boring mills are used in industries such as aerospace, automotive, defense, and energy, where precision and accuracy are crucial. They are also used in job shops and large-scale manufacturing facilities for a wide range of applications.

How often should a CNC boring mill be maintained?

A CNC boring mill should be maintained regularly, following the manufacturer’s guidelines. This includes daily, weekly, and monthly inspections, as well as replacing worn-out components and lubricating moving parts. Proper maintenance can prevent breakdowns and prolong the machine’s lifespan.

Can a CNC boring mill be used for both milling and boring operations?

Yes, a CNC boring mill can perform both milling and boring operations. The machine’s spindle speed, power, and cutting tools can be adjusted to perform different operations depending on the material and desired results.

Weish CNC Co., Ltd is a high-tech enterprise with equipment such as Laser Engraving and Cutting Machines,grinding machine,CNC machining center,Fiber Laser Cutting Machines,gear hobbing machine,bending machine,radial drilling machine. Widely used in professional fields such as shipbuilding,printing,steel,shipbuilding,machinery,automobile,energy,aerospace.

Our main products include single coulumn lathe,Vertical lathe,5 Axis Milling Head A/C,planner type boring,CNC vertical lathe,Router machine,horizontal boring machine(table type),CNC machine center,5 axis machining center,Cnc Horizontal Machining Center, etc.

CNC boring mills are essential machines in the manufacturing industry, offering high precision, versatility, and efficiency. Proper maintenance, training, and tool selection are crucial for their optimal performance and longevity. As the demand for these machines continues to grow, it is essential to keep up with the latest technology and advancements in the field to stay competitive in the market.