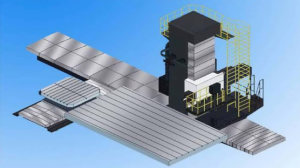

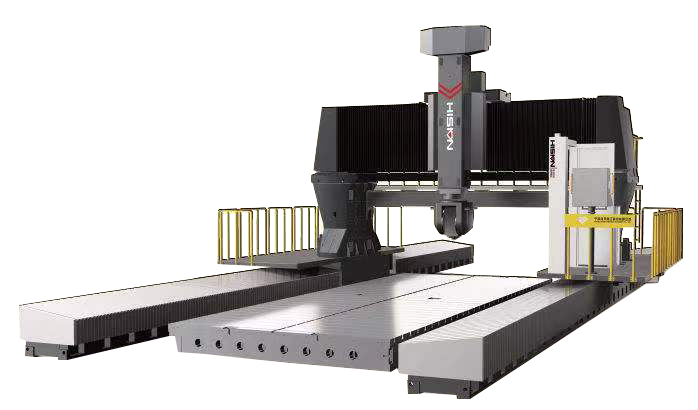

Weish CNC, a leading CNC machine factory and supplier, specializes in providing state-of-the-art machining solutions. As a trusted wholesaler and supply agent, Weish CNC offers a range of advanced machines, including the DHX Gantry Machining Center and the 5 Axis Gantry Machining Center. This detailed product description article explores the applications and benefits of the DHX Gantry Machining Center, highlighting its capabilities and key features.

Introduction to DHX Gantry Machining Center

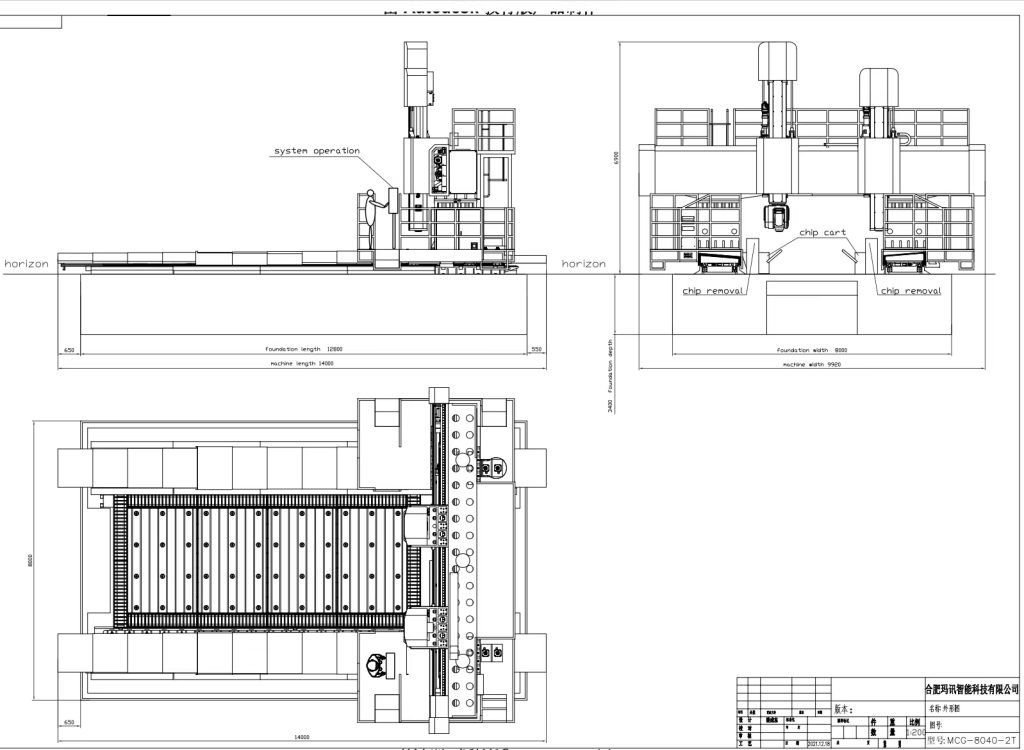

The DHX Gantry Machining Center is a versatile and powerful machine designed to handle complex and large-scale machining tasks with precision and efficiency. It is an essential tool in various industries, offering unparalleled performance and reliability.

Applications of DHX Gantry Machining Center

- Aerospace Industry

In the aerospace sector, precision and accuracy are paramount. The DHX Gantry Machining Center excels in machining intricate components for aircraft, including turbine blades, structural parts, and engine components. Its 5-axis capability ensures the production of complex geometries with tight tolerances.

- Automotive Industry

The automotive industry relies on the DHX Gantry Machining Center for manufacturing critical parts such as engine blocks, transmission housings, and chassis components. Its robust design and high-speed capabilities enable efficient production, reducing lead times and improving productivity.

- Energy Sector

For the energy sector, particularly in the production of wind turbine components and large-scale power generation equipment, the DHX Gantry Machining Center offers the precision and capacity needed to handle oversized and heavy parts.

- Tool and Die Manufacturing

In tool and die manufacturing, the DHX Gantry Machining Center is used to create molds, dies, and precision tools. Its ability to machine complex shapes and fine details makes it an invaluable asset in this industry.

Key Features of DHX Gantry Machining Center

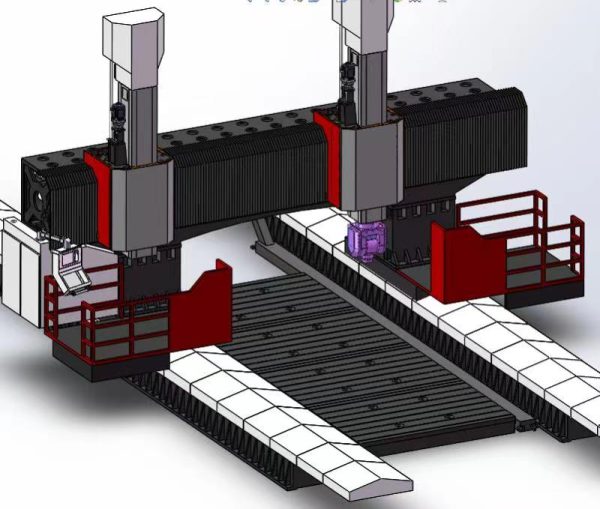

- 5 Axis Capability

The 5 Axis Gantry Machining Center allows for simultaneous movement along five axes, enabling the machining of complex shapes and surfaces in a single setup. This reduces the need for multiple machine setups, enhancing efficiency and accuracy.

- High Precision and Accuracy

Equipped with advanced control systems and high-precision components, the DHX Gantry Machining Center delivers exceptional accuracy and repeatability, ensuring the highest quality of machined parts.

- Robust Construction

Designed for durability and stability, the DHX Gantry Machining Center features a robust gantry structure that minimizes vibrations and enhances machining accuracy, even during heavy-duty operations.

- Versatility

The DHX Gantry Machining Center is suitable for a wide range of materials, including metals, composites, and plastics. This versatility makes it an ideal choice for various industrial applications.

Expert Insights on DHX Gantry Machining Center

Weish CNC is dedicated to providing cutting-edge machining solutions that meet the evolving needs of our clients. Our DHX Gantry Machining Center is engineered to deliver superior performance, precision, and reliability.

The 5 Axis Gantry Machining Center offers unmatched precision and flexibility, making it the ideal choice for complex machining tasks across multiple industries. Its advanced features ensure high productivity and exceptional part quality.

Conclusion

The DHX Gantry Machining Center from Weish CNC is a versatile and powerful solution for a wide range of industrial applications. Its advanced capabilities, including 5-axis machining, high precision, and robust construction, make it an invaluable asset in industries such as aerospace, automotive, energy, and tool and die manufacturing. As a leading CNC machine factory, wholesaler, and supply agent, Weish CNC is committed to delivering top-quality machining solutions that enhance productivity and efficiency. Contact Weish CNC today to learn more about the DHX Gantry Machining Center and how it can benefit your operations.