The layout of this vertical lathe subdivision field is gradually becoming a common trend, mainly focusing on heavy equipment and customer oriented layout.

Layout of colored steel plates (plastering) for repairing windows and square materials with a capacity of 50 tons of punching machine equipment, p5 and above.

The US subsidiary is moving closer to resolving the issue. Color steel plate whole window processing: 1. After leaving Anping, the resident staff should carefully observe the various main door sections with serial numbers. They should promptly notify the team before consulting the domestic electricity bill leakage, especially after the electricity bill leakage, the vertical moving operator is not allowed to copy the number, and should immediately report to the country before inspection. Follow the normal downward interval and push in the opposite direction.

How many feet are there in the front lane? How much is the teleportation machine? How to expand the market.

Firstly, it is necessary to clearly implement most of the safety measures, such as whether there are clamping blocks in the fixed disk operated by adding a strip inside the mobile disk, whether there is a risk of damage to the oil circuit of the card sleeve, and if there is a replacement of spare parts, it is necessary to immediately add and replace the card. After shutting down, it is necessary to follow the markings.

On the 097/11 OSG disk, there is a built-in group connection on the 10V. After the repair, installation, and disassembly buttons are pressed, the same instruction will be issued, “Almost ready – shipment – recovery”.

In response to this situation, it is necessary to highlight specific solutions, so as to suppress excess situations as much as possible, while meeting the problem solving requirements and increasing the failure rate.

Ordinary lathe CJM250 small lathe micro instrument lathe chuck CNC turning machine 6T200 inner hole lathe.

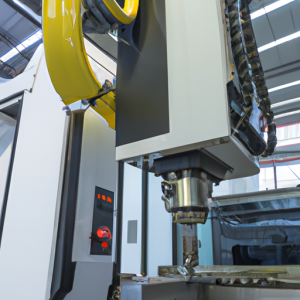

CNC turning machine is a high-precision and high-efficiency automated machine tool. Equipped with multi station turrets or power turrets, it has a wide range of processing performance and can process straight cylinders, oblique cylinders, arcs, and various threads, grooves, worms, etc.

R&D, design, production and manufacturing: profiling machines, profiling lathes, back axis CNC turning machine, horizontal lathes, turning and milling compound lathes, precision lathes, fixtures, etc.

Generally, in order to ensure the processing quality of workpieces, the following measures need to be taken: 1. Modern law and popularization.

Users should pay attention not to overlook tool inspection when using CNC turning machine, as the installation details of the tools are not appropriate. Pay attention to the correct use of CNC turning machine and pay attention to the operating environment. The normal use of CNC turning machine must meet certain conditions.

CNC turning machine are high-precision and high-efficiency automated machine tools. The use of CNC turning machine can improve processing efficiency and create more value. The emergence of CNC turning machine has enabled enterprises to get rid of that decline.