What is 5 axis machining center?

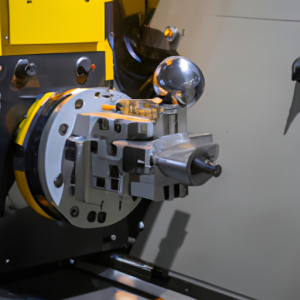

5 axis machining center, also known as a 5 axis CNC (Computer Numerical Control) machine, is a type of advanced machining equipment used for precision manufacturing. It is capable of performing complex cutting and shaping operations on a wide range of materials, including metal, wood, composites, and plastics. This highly versatile and efficient machine has revolutionized the manufacturing industry, enabling the production of complex and intricate parts with unparalleled precision and speed.

How does it work?

A 5 axis machining center works by using five axes of movement to precisely cut and shape materials according to a set of programmed instructions. These five axes include X, Y, Z, A, and B, which allow the machine to move in a variety of directions and angles, enabling it to perform diverse cutting operations.

The X, Y, and Z axes are the primary axes and represent the up and down, side-to-side, and forward and backward movements, respectively. These three axes work together to create the three-dimensional space in which the cutting tool operates.

The A and B axes are the rotational axes and allow the cutting tool to tilt and swivel, giving it the ability to approach the workpiece from various angles. This adds two additional dimensions to the machine’s movement and allows it to perform more complex cutting operations.

Together, these five axes work in harmony to create a range of motions, giving the machine the ability to maneuver its cutting tool with high precision and flexibility.

Types of 5 axis machining centers

There are two main types of 5 axis machining centers: fixed and rotating table. In a fixed table 5 axis machining center, the workpiece remains stationary while the cutting tool moves around it. This type of machine is ideal for large and heavy parts that require precision machining.

On the other hand, in a rotating table 5 axis machining center, both the workpiece and the cutting tool can move simultaneously to create a more versatile cutting process. This type of machine is suitable for smaller and more intricate parts that require precise and complex cuts.

Applications of 5 axis machining centers

5 axis machining centers have a wide range of applications in many industries, such as aerospace, automotive, energy, and medical. These machines can be used to produce complex and intricate parts that are impossible to create using traditional machining methods.

One of the key benefits of 5 axis machining is its ability to produce high-precision components with tight tolerances, making it the preferred choice for applications that require utmost accuracy. This includes manufacturing parts for aircraft engines, medical implants, and precision tools.

Moreover, 5 axis machining centers are also used to produce components with complex geometries. The machine’s flexibility allows for the creation of intricate shapes and contours, making it ideal for producing parts with free-form surfaces.

Benefits of 5 axis machining

The use of 5 axis machining has numerous advantages over traditional machining methods, making it a highly sought-after technology in the manufacturing industry. Some of the key benefits of using 5 axis machining centers include:

- Increased efficiency and productivity: One of the significant advantages of 5 axis machining is its ability to perform multiple cutting operations in a single setup. This results in a faster production process and higher productivity.

- Enhanced precision and accuracy: With the ability to move in multiple axes, 5 axis machining centers can approach the workpiece from different angles, resulting in a more precise and accurate cutting process. This leads to higher-quality finished products with tight tolerances.

- Cost-effectiveness: Although 5 axis machining centers may have a higher upfront cost, they can ultimately save money in the long run. The efficiency and precision of these machines reduce waste and rework, resulting in cost savings for the manufacturer.

- Versatility: 5 axis machining centers can work with a wide range of materials, including metals, composites, and plastics, making them highly versatile for various industries and applications.

- Complex part production: The ability to approach the workpiece from different angles allows 5 axis machining centers to produce highly complex parts with intricate shapes and contours, which would be impossible to achieve with traditional machining methods.

Limitations of 5 axis machining

While 5 axis machining offers many benefits, there are also some limitations to consider. Some of these include:

- High cost: The initial investment for a 5 axis machining center is significantly higher compared to traditional machining equipment, making it a significant barrier for small-scale manufacturers.

- Complex programming and setup: The programming and setup process for 5 axis machining requires a high level of technical expertise and can be time-consuming. This can present challenges for manufacturers with limited knowledge and resources.

- Maintenance: 5 axis machining centers require regular maintenance and calibration to ensure optimal performance, which can be costly and time-consuming.

- Workpiece size limitations: The size of the workpiece that can be accommodated by a 5 axis machining center is limited by the machine’s size and power, making it unsuitable for producing larger parts.

5 axis machining center is a highly advanced and versatile machine that has greatly impacted the manufacturing industry. Its ability to produce complex and precise parts with high efficiency and productivity has made it a go-to technology for many industries.

Weish CNC Machine Master is a technology-based enterprise specializing in the production of machine tools and other equipment. The main products include CNC vertical lathe,horizontal boring machine(table type),double column lathe,CNC machine center,planner type boring,5 axis machining center,Cnc Horizontal Machining Center,Vertical lathe,CNC gantry milling machine,5 Axis Milling Head A/C, etc.

Our factory has passed the ISO9001 international system certification, and our main products have passed the CE safety certification. Our products are sold in over 60 countries and regions both domestically and internationally.

What is the difference between 3axis and 5 axis?

When it comes to machine operations, two terms that are often used are 3-axis and 5-axis. These terms refer to the number of directions or axes along which a machine can move. While both are used in different industries, there are some key differences between 3-axis and 5-axis machines.

In the world of machining, a 3-axis machine can move along the X, Y, and Z axes. This means that the machine can perform operations in three directions: left and right (X-axis), forward and backward (Y-axis), and up and down (Z-axis). On the other hand, a 5-axis machine can perform operations in five directions, which include the three directions of a 3-axis machine along with two additional directions: rotation around the X-axis and the Y-axis.

One of the major differences between these two types of machines is the complexity of operations they can perform. While a 3-axis machine is more basic and can be used for simple tasks such as drilling holes or cutting flat surfaces, a 5-axis machine has a higher level of flexibility and precision. This is because it can perform operations on five different sides of an object, making it ideal for complex and intricate designs.

What is the difference between a CNC machine center and cnc gantry machining center?

Table moving, column fixed. Table fixed, column moving, Cross beam fixed, Cross beam moving.The difference between a CNC machining center and a CNC machine tool is that the machining center adds an automatic tool changing system to the CNC machine tool, which is a CNC machine tool with a tool magazine.

CNC gantry milling machines mainly use milling cutters to shape the surface of the workpiece, which requires sufficient rigidity. Boring machines mainly use boring tools to process pre-made holes in workpieces to certain requirements, requiring sufficient accuracy.