A vertical lathe, also known as a vertical turning center, is a machine tool used to shape metals and other materials by rotating them on a vertical axis. Unlike traditional lathes, which have a horizontal axis, vertical lathes have a spindle mounted on a vertical column. This allows for the workpiece to be held upright, making it easier to access and manipulate, and providing greater stability and precision during the machining process.

History of Vertical Lathes

The earliest known vertical lathe was invented by the Egyptians around 250 BC, but it was not until the Industrial Revolution in the late 1700s that modern vertical lathes began to emerge. These early machines were driven by steam power and were used primarily for large-scale industrial production.

In the late 19th and early 20th centuries, the development of electric motors and improved cutting tools led to significant advancements in vertical lathe technology. The introduction of numerical control (NC) and computer numerical control (CNC) in the 1950s and 1960s further revolutionized the capabilities of vertical lathes, making them more efficient, accurate, and versatile.

Today, vertical lathes are widely used in various industries, including aerospace, automotive, and energy, to produce precision components such as gears, shafts, and turbines.

How Vertical Lathes Work

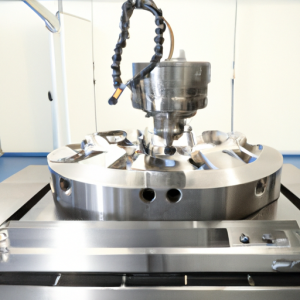

The basic principle of a vertical lathe remains the same as a traditional lathe; the workpiece is mounted on a spindle and rotated at high speeds while a cutter, or cutting tool, removes material to achieve the desired shape. However, in a vertical lathe, the workpiece is held in a vertical position on a horizontal table, and the cutter moves horizontally along the vertical axis.

Vertical lathes come in a variety of sizes, from small tabletop machines to large industrial models capable of handling workpieces weighing several tons. The size and power of a vertical lathe depend on the type and size of workpiece it is designed to handle.

Types of Vertical Lathes

There are several types of vertical lathes, each with its own unique features and capabilities. The most common types include single-column, double-column, and multi-column vertical lathes.

Single-column vertical lathes, also known as single-column boring mills, have a single column supporting the headstock, and the workpiece is held in a chuck or on a faceplate attached to the spindle. These lathes are commonly used for heavy-duty and high-precision machining.

Double-column vertical lathes, also known as double-column boring mills, have two columns supporting the headstock and workpieces. These lathes are typically used for larger workpieces that require more stability and heavier cutting.

Multi-column vertical lathes, also known as vertical turning and milling centers, have multiple columns supporting the headstock, allowing for greater stability and rigidity during the machining process. These machines are capable of performing both turning and milling operations, making them highly versatile and suitable for complex and high-precision workpieces.

Benefits of Vertical Lathes

Vertical lathes offer several advantages over traditional horizontal lathes, including:

- Greater Stability and Rigidity: The vertical orientation of the workpiece on a vertical lathe provides better support and stability, making it easier to machine large, heavy, or irregularly shaped parts.

- High Precision: Vertical lathes are designed to produce precision components with tight tolerances, making them ideal for industries such as aerospace and automotive, where precision is crucial.

- Improved Accessibility: The vertical design of a vertical lathe allows for easier access to the workpiece, making it easier to load and unload, as well as providing better visibility during the machining process.

- Versatility: With the ability to perform both turning and milling operations, multi-column vertical lathes offer a wide range of capabilities, making them suitable for a variety of applications.

- Reduced Floor Space: Due to their vertical orientation, these machines take up less floor space compared to horizontal lathes, making them a more efficient use of space in a production facility.

WEISH CNC MASTER is a technology-based enterprise specializing in the production of machine tools and other equipment. The main products include CNC boring mill,Vertical lathe,CNC vertical lathe,horizontal boring machine(table type),5 Axis Milling Head A/C,CNC machine center,CNC gantry milling machine,5 axis machining center,Router machine,single coulumn lathe, etc.

Our factory has passed the ISO9001 international system certification, and our main products have passed the CE safety certification. Our products are sold in over 60 countries and regions both domestically and internationally.