Exploring the Benefits of High-Performance CNC Machine Centers for Precision Manufacturing

The use of high-performance CNC machine centers for precision manufacturing has become increasingly popular in recent years, and for good reason. Compared to traditional manufacturing methods, CNC machine centers offer a number of advantages that make them an attractive option for many manufacturers. In this article, we will explore the benefits of high-performance CNC machine centers for precision manufacturing and compare them to traditional manufacturing methods.

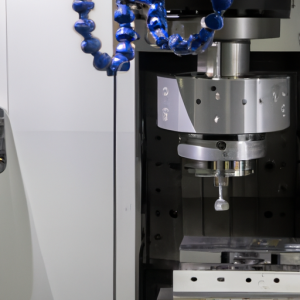

One of the primary advantages of CNC machine centers is their ability to produce parts with greater accuracy and precision than traditional manufacturing methods. CNC machines are programmed with precise instructions that allow them to produce parts with exacting tolerances. This level of accuracy is not possible with traditional manufacturing methods, which rely on manual labor and are subject to human error. Additionally, CNC machines can produce parts with complex geometries that would be difficult or impossible to produce with traditional methods.

Another benefit of CNC machine centers is their ability to produce parts quickly and efficiently. CNC machines are programmed to run continuously, allowing them to produce parts in large quantities with minimal downtime. This makes them ideal for high-volume production runs. Additionally, CNC machines can be programmed to produce parts with a variety of materials, allowing manufacturers to produce parts with different properties and characteristics.

Finally, CNC machine centers are relatively easy to maintain and operate. CNC machines are designed to be user-friendly, allowing operators to quickly and easily program and operate the machines. This makes them ideal for manufacturers who need to quickly and efficiently produce parts with minimal downtime.

In conclusion, high-performance CNC machine centers offer a number of advantages over traditional manufacturing methods. They are capable of producing parts with greater accuracy and precision, can produce parts quickly and efficiently, and are relatively easy to maintain and operate. For these reasons, CNC machine centers are becoming increasingly popular for precision manufacturing.

How to Maximize Efficiency with High-Performance CNC Machine Centers for Precision Manufacturing

High-performance CNC machine centers are essential for precision manufacturing, as they provide the accuracy and repeatability needed to produce complex parts with tight tolerances. To maximize efficiency, manufacturers must consider the following factors when selecting a CNC machine center: speed, accuracy, repeatability, and automation.

Speed is a key factor in maximizing efficiency. High-performance CNC machine centers are designed to operate at higher speeds than traditional CNC machines, allowing for faster production times. This can be especially beneficial for high-volume production runs, as it reduces the amount of time needed to complete each part.

Accuracy is also important for precision manufacturing. High-performance CNC machine centers are designed to produce parts with tight tolerances, ensuring that each part is produced to exact specifications. This helps to reduce waste and improve the quality of the finished product.

Repeatability is another important factor in maximizing efficiency. High-performance CNC machine centers are designed to produce parts with consistent accuracy and repeatability, allowing for faster production times and fewer errors. This helps to reduce the amount of time needed to complete each part and ensures that each part is produced to exact specifications.

Finally, automation is an important factor in maximizing efficiency. High-performance CNC machine centers are designed to be automated, allowing for faster production times and fewer errors. Automation also helps to reduce the amount of time needed to complete each part, as well as reduce the amount of manual labor required.

By considering these factors when selecting a CNC machine center, manufacturers can maximize efficiency and ensure that each part is produced to exact specifications. High-performance CNC machine centers provide the accuracy and repeatability needed to produce complex parts with tight tolerances, allowing for faster production times and fewer errors. This helps to reduce waste and improve the quality of the finished product.