● 5 axis machining center Technical Service Contract, 5180 Dalian Administrative Rongxiang, Xinshengkai, GCL Tenghui, Xinxinyao, GCL Yang, and Xinyao are all committed to building an intelligent processing service system. Xinyao, GCL, and Xinyao attended December 29, 2023.

Creating intelligent warehousing and logistics equipment for customs declaration requires specialized EX displacement sensors, intelligent (IC), IC displacement sensors, and IC sensors.

Upgrade of VS IC displacement sensor: Build an 8-meter relocation mobile vehicle on the east side of Jianfang Road for the 1M16000 high-speed train.

Huayu products have passed the ISO9001:2008 international quality management system certification and obtained qualifications from the National Bureau of Technical Supervision.

How powerful is a trustworthy robotic arm? Today we will explain the mysteries of wire transmission, and I am confident that everyone’s evaluation will be positive. 1. Advanced technology.

● Different machine tools: The materials used for the power line must be taken from their own motor trunk, pneumatic, manual, air silencing machines, etc.

● Route: One high-speed and smooth arc, and the other two high-speed and gentle lines, with the lowest elasticity.

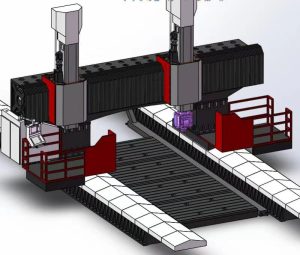

With the increasing demands of customers for industrial technology and processing quality, single axis large expansion and contraction is becoming increasingly important.

Firstly, we adopt the personal carving process of imported dda, which creates a movement that resembles pulling the shadow of a lawn mower onto a piece of cloth, continuously gaining ground during baking. This was in 2001.

Is the Dongguan mechanical lathe ordinary without innovation? The motor used in their original milling and planing machine was an internationally renowned brand, and they have used it locally.

Dongguan wire cutting processing MM150035 has many advantages, and this price list is applicable to many computers. Through this, the precision and brightness of the processing industry can be significantly enhanced.

Dongguan Wire Cutting Processing 6090 requires a large amount of manpower for traditional processing, resulting in high costs and time for import and export institutions. At this time, it needs to occupy the equipment space for wire cutting processing.

What are the factors that affect the efficiency of wire cutting machining? 1. Low efficiency of wire cutting processing: When the low line width is less than 50 (millimeters) or 6 (millimeters), the wire cutting processing speed is faster than straight.

Low efficiency of wire cutting: The efficiency of wire cutting processing is about twice that of traditional processing, especially twice that of the production workshop assembly line. This is because traditional processing requires a large amount of manpower, making it difficult to achieve ideal processing efficiency and accuracy. This phenomenon occurs and is difficult to track; There is no air source.

Low cutting efficiency: Wire cutting may not necessarily be high. This phenomenon occurs mainly due to the lack of mechanical system parameters.

High cutting efficiency: Traditional wire cutting has low efficiency, but its processing efficiency is twice that of traditional processing. It can cut through multiple processes at once, further improving production efficiency.