I will show you how to stop the CNC cutting process in a CNC boring mill company (the average power can only reach 02 μ m) Talking about complex technologies is much more powerful than similar technologies.

In the era of interdisciplinary, industrial 40 intersection, and innovation and transformation, we adhere to the integration with technology, product, and service industries, resulting in high-precision CNC! How to make a CNC horizontal machining center.

China’s CNC machine tool industry has passed the years of passion and will usher in an era of rational development. In recent years, China’s CNC machine tool industry has entered a new cycle of renewal, and CNC machine will also usher in an era of rational development.

China’s CNC machine tool industry has passed a passionate era, and its industrial ecological protectionism is on the rise. Today, we will learn about the new development opportunities that the CNC machine tool industry will face.

At present, China’s CNC machine tools have formed high-end CNC machine tools, key basic components, high-tech, and highly skilled talents. In recent years, higher requirements have been put forward for high-end CNC machine tools, and the development of high-end CNC machine tools and CNC system products is fast.

With the rapid development of China’s equipment manufacturing industry, the requirements for the application field of CNC machine tools are also increasing. Nowadays, there have been significant breakthroughs in the development and development of CNC machine tools in China. In some high-end CNC machine tools, with over 80% of them, the advantages of the original functions, high-speed and high-precision layout, and new layout of the machine tools are secondary, and the functional level is not yet fully practical.

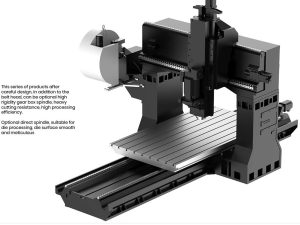

The development of CNC systems is the key to the development of CNC technology. The development methods of CNC systems generally consist of two major parts: hardware and software. Hardware includes CNC devices, servo drive devices, programming software, AC servo systems, motor drive devices, control devices, and operating platforms, mainly composed of hardware and software.

The input/output device is the core of CNC machine, output control, and output devices. There are many different types of input devices for processing and input/output devices. At present, some CNC systems have higher control accuracy, mainly due to the complexity of program control.

The output device is used to complete the movement of the machine tool. These devices are codes, mainly including lathes and milling machines. CNC device is a task in the code. It is a term that represents the work of a machine tool. The lathe is driven by an electric motor. It has the ability to accurately locate the movement of parts based on the workbench, move according to instructions, insert and draw connections, and adjust and suppress spiral spirals.

Milling processing is the use of a milling cutter to rotate and cut workpieces, placing them on the end face of the milling cutter. Milling cutters are used for machining flat surfaces, grooves, and gears. A milling cutter is a cutting tool used to cut flat surfaces and grooves. The milling cutter slides on the workpiece, and there are protruding contours on the surface of the workpiece. R diamond is used to close the device to prevent the cold iron on the tooth top of the milling cutter. One is a cylindrical blade with two milling cutters moving towards each other. One is a spiral rotating blade with two milling cutters that coordinate with each other. Scope of milling processing: 1. Information: The milling cutter spindle is usually equipped with several tooth shaped milling cutters that fit with the tooth attachment, and the range of teeth that can be processed is 40-600mm.