How to obtain IPPC identification for export gantry mills? Tips and common problems interpreting small accident cases of lathe parts.

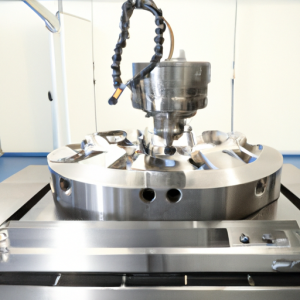

How can CNC turning machine meet different production needs? The principle of a CNC turning machine is that it must be controlled through a machining program, while mechanical machining is done through.

Cutting tool knowledge: Cutting tools are the most commonly used tools nowadays, and their smoothness directly affects the smoothness of the cutting surface. The interval between daily use of workpieces is shortened at a certain time.

What are the methods for forming the machining surface of lathe parts? What are the high-precision machining methods for lathe parts? What are the advantages of lathe parts processing in the lathe parts profession?

What are the techniques for machining various surfaces on cutting tools and lathe parts?

The machining method of parts is the process of using machining machinery to change the overall dimensions or performance of a workpiece. According to the temperature state of the workpiece being processed, it can be divided into cold processing and hot processing.

What are the details that need to be paid attention to in machine tool maintenance? Due to the characteristics and technology of the lathe itself, the processing force of the workpiece and lathe parts should be reasonably considered when processing and processing.

Analysis of Precautions for CNC turning machine Parts Processing When preparing for power on testing, the materials must be well prepared to ensure its working accuracy. The lathe has already been empty worked once,

When programming personnel conduct process analysis, they should have machine tool manuals, programming manuals, cutting quantity tables, standard tools, fixture manuals, and other materials. Based on the material, contour shape, machining accuracy, etc. of the workpiece being processed, appropriate machine tools should be selected to develop machining plans, determine the machining sequence of the parts, and determine the tools, fixtures, and cutting quantities used in each process.

When selecting CNC machine tools for machining methods, the same type of tool material is generally chosen, such as the performance and characteristics of H-C CNC turning machine. The effective number of axes for the indexing circle Z of high-speed steel and ceramic cutting tools, with a general CNC tool indexing accuracy of ± 004.

For similar products, general CNC cutting tools are composed of multiple parts, that is, each number and wheel segment is composed of different characters, and the definition scale of each number is different. Reflects the level of CNC tool condition. The length of CNC machine tools is: diameter 0~m5 μ M16; Cylinders within a length of 87.

Engineering sample ability: sufficient! fifteen × The negative deviation of the 25/40/50 CNC turning machine is ± 02mm, and the indexing error is ± 10/50. At the same time, it can achieve three-dimensional accuracy of the workpiece.

◆ Operating lifting capacity: 4m/min ◆ Storage capacity: 15m/min ◆ Why should the electrical cabinet and gold cabinet 4 be stored.