CNC routers are a great way to boost your efficiency and productivity in the manufacturing process. They are used to cut, shape, and engrave a variety of materials, including wood, plastic, metal, and composites. CNC routers are computer-controlled machines that use a variety of cutting tools to create intricate designs and shapes.

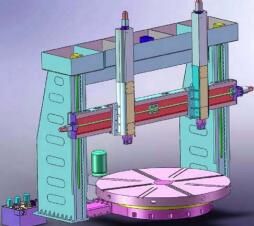

When selecting a CNC router machine, it is important to consider the size of the material you will be working with, the type of material, and the complexity of the design. The size of the material will determine the size of the machine you need. If you are working with large pieces of material, you will need a larger machine. If you are working with smaller pieces of material, you will need a smaller machine.

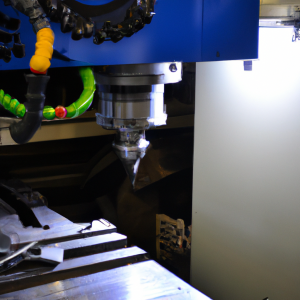

The type of material you are working with will also determine the type of machine you need. Different materials require different cutting tools and speeds. For example, wood requires a different type of cutting tool than metal. You will also need to consider the complexity of the design you are creating. If you are creating intricate designs, you will need a more powerful machine.

When selecting a CNC router machine, it is important to consider the features and capabilities of the machine. Some machines are designed for specific tasks, such as engraving or cutting. Other machines are designed for more general tasks, such as cutting and shaping. It is important to select a machine that has the features and capabilities you need for your specific project.

It is also important to consider the cost of the machine. CNC routers can range in price from a few hundred dollars to several thousand dollars. The cost of the machine will depend on the size, features, and capabilities of the machine.

Finally, it is important to consider the maintenance and support of the machine. CNC routers require regular maintenance and support to ensure they are running properly. It is important to select a machine that has a good warranty and support system.

CNC routers are a great way to boost your efficiency and productivity in the manufacturing process. When selecting a CNC router machine, it is important to consider the size of the material you will be working with, the type of material, the complexity of the design, the features and capabilities of the machine, the cost of the machine, and the maintenance and support of the machine. By selecting the right CNC router machine, you can ensure that your manufacturing process is efficient and productive.