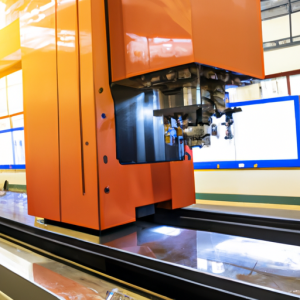

CNC machine centers are computer-controlled machines used for cutting and shaping materials. They are used in a variety of industries, including automotive, aerospace, and medical. Proper operation and maintenance of CNC machine centers is essential for ensuring the safety of operators and the quality of the finished product.

Before operating a CNC machine center, operators should be trained in the proper use of the machine and its safety features. Operators should also be familiar with the machine’s control panel and the various settings and functions.

When operating a CNC machine center, operators should always wear protective gear, such as safety glasses and gloves. They should also ensure that the machine is properly lubricated and that all moving parts are free of debris. Operators should also check the machine’s coolant levels and make sure that the cutting tools are sharp and in good condition.

Regular maintenance of a CNC machine center is essential for ensuring its proper operation. This includes checking the machine’s coolant levels, lubricating all moving parts, and inspecting the cutting tools for wear and tear. Operators should also check the machine’s control panel for any errors or malfunctions.

In addition to regular maintenance, operators should also perform periodic inspections of the machine’s components. This includes checking for any signs of wear or damage, such as cracks, chips, or corrosion. If any of these are found, the machine should be taken out of service until the issue is resolved.

Finally, operators should always follow the manufacturer’s instructions for operating and maintaining the CNC machine center. This includes following the recommended maintenance schedule and using the correct tools and materials for the job. By following these guidelines, operators can ensure that their CNC machine center is operating safely and efficiently.