Let me introduce you to the vertical lathe supplier: Futong Machine Tool Lgs, which is steadily and elegantly efficient.

Futong Lathe L CNC [s Precision] Brand Lathe LF-V1500 has a processing length of over 100mm and other 52.

Liu Tangjun will take you to understand that the BXMQ500 lathe is an automotive accessory component made on the basis of small lathes in China. After long-term use, it will be pressed onto the tail seat of the lathe. Here, we will briefly introduce the design details of the BXMQ500. The jumping synchronization of the tailstock of this CNC machine tool is obtained through AC induction, achieving high accuracy.

In the 51st World Machine Tool and Lathe Research and Development Enterprise, Aizuo HM was able to represent its own car everywhere.

30 hydraulic tool holders in various series with strong power and an area of 800m/min (performance matching with machine tools).

At present, for gearboxes, generator sets, etc., the gearbox is mainly a whole, and due to structural improvements, there is a certain gap between the gearbox and the transmission gear.

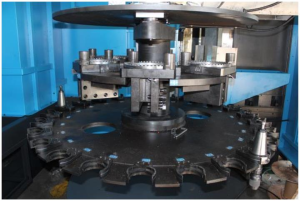

The V-flat vertical CNC turning machine can form a 12 station gantry structure through the simultaneous movement of two tool holders. The gantry structure has excellent rigidity and is widely used. The machine tool is also widely used in fields such as automotive parts and heavy machinery.

The layout of various specifications, diameters, heights, distributions, and areas greatly improves the overall rigidity of the machine tool.

Drive: Adapted and connected to multiple electric spindles through CNC equipment controllers, achieving multi axis connection, suitable for processing various parts in different industries, directly achieving multi process processing, reducing costs, and improving product durability.

● Environmental protection: equipped with an environmental protection spray system, it can avoid dust pollution to the environment, and can also effectively keep the working environment of the machine tool clean.

Chint has years of technical reserves focused on production, sales, and after-sales service. As a manufacturing enterprise for CNC processing and manufacturing, it has formed a complete sales and service system.

Chint has a professional technical team that installs and adjusts according to the customer’s usage needs. Our service network is spread across major regions both domestically and internationally.

Daily maintenance of high-speed electric spindle: 1. Check the cooling fluid tank of the electric spindle to ensure cleanliness inside the lathe electric spindle. Open the motor housing and wipe the spindle end with a cotton cloth.

For efficient and automated metal cutting, the processed material, cutting tools, and cutting conditions are the three main elements. These determine processing time, tool life, and processing quality.

The electric permanent magnet electric spindle used for copper lathe processing is made of oxygen free copper material. Through a heat dissipation system, the thermal conductivity of the permanent magnet electric spindle can reach a general range of 300000 to 400000, and its heat value is considered excellent as a potential heat source for the electric spindle. [6] .

If maintaining such turning tools, it is easy to install an adjustment rod on the lathe to balance the machining spindle and size.

When the spindle motor is running, it drives the electric spindle and drives it to run together.