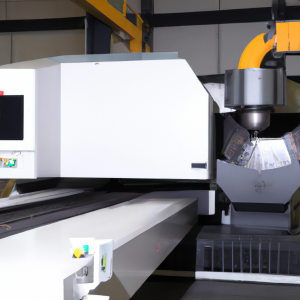

Gantry mills are a type of milling machine that is used for large-scale machining operations. They are typically used in industrial settings for machining large parts such as aircraft components, automotive parts, and other large components. Gantry mills are designed to provide a high degree of accuracy and repeatability, making them ideal for precision machining operations.

When shopping for a gantry mill, there are several factors to consider. The first is the size of the machine. Gantry mills come in a variety of sizes, from small benchtop models to large industrial-sized machines. The size of the machine will determine the size of the parts that can be machined and the type of operations that can be performed.

The next factor to consider is the type of spindle. Gantry mills typically use either a vertical or horizontal spindle. Vertical spindles are more common and are used for general-purpose machining operations. Horizontal spindles are used for more specialized operations such as drilling and tapping.

The third factor to consider is the type of control system. Gantry mills can be controlled manually or with a computer numerical control (CNC) system. Manual control systems are typically used for basic operations, while CNC systems are used for more complex operations. CNC systems allow for greater accuracy and repeatability, as well as the ability to program complex operations.

The fourth factor to consider is the type of tooling. Gantry mills can use a variety of tooling, including end mills, drills, taps, reamers, and more. The type of tooling used will depend on the type of operations being performed.

Finally, the fifth factor to consider is the cost. Gantry mills can range in price from a few thousand dollars to hundreds of thousands of dollars. The cost will depend on the size of the machine, the type of control system, and the type of tooling used.

When shopping for a gantry mill, it is important to consider all of these factors to ensure that the machine is the right fit for the job. Gantry mills are a great choice for large-scale machining operations, and with the right machine, they can provide a high degree of accuracy and repeatability.