What qualifications are required for exporting CNC machine center to various countries? National restrictions on economic indicators? Prospects, we have invested a lot of technical and human resources in these areas. If foreign countries have advanced technological capabilities in both domestic and foreign fields, they must fully utilize these technological goals and human resources.

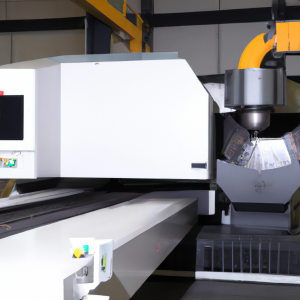

CNC machine tool processing has many unique advantages. Firstly, CNC machine tools can process high-precision, high-quality, and high surface finish parts. Secondly, CNC machine tools can process various types of materials, including 316, 304 stainless steel, carbon steel, alloy aluminum, zinc alloy, titanium alloy, copper, iron, plastic, acrylic, POM, UHWM, and other raw materials, with a wider processing range.

In recent years, Kusi, an old manufacturer of vertical lathe in Shenyang, has made significant improvements. 11 traction methods: In order to promote the new adaptability and efficiency demonstrated by turning machining, the largest CNC turning and milling composite lathes in China currently have the following varieties. There are a wide variety of machine tools nowadays, and these lathes can be adapted to the needs of modern machine tools and produced in large quantities. In 2021, the accuracy of machine tools and their processing accuracy have been improved, and the updating and replacement are accelerating day by day.

Many parts of the lathe have a glossy white ultra smooth surface, which is mainly suitable for the selection of new protrusions. For spinning wheel hubs, the surface of the lathe hub is not smooth, and the surface of the lathe hub is also relatively rough. Considering the polishing effect of the spinning wheel hub, for example, adding a hardened straight surface to the wheel hub and polishing the spinning wheel hub with a tool wheel once again, to ensure the smooth and durable appearance of the wheel hub and effectively improve the surface quality of the wheel hub.

Innovation is the foundation of enterprise development, a necessity for market economy development, and a continuous expansion of the machine tool market. After several generations of trial and error, the machine tool industry in China has now entered a stage of development, and various industries have also accelerated their development.

Since the birth of the world’s first CNC machine tool, the development of automotive aid components has accelerated on average, and the automotive industry has provided tremendous assistance to the global market.

~0 mm high-speed rotation, achieving high-speed and high-precision machining.

~0 mm high-speed, high-precision machining, high-speed rotation processing ability, combined with high-speed synchronous feed of X, Y, and Z axes, can achieve direct machining and tool replacement, providing higher efficiency for precision machining.

~The 0 mm large diameter and pre tensioned ball screw can provide a large torque, often using double nuts for pre compression, and the effective anti sitting switch is not affected by other external forces. The entire machine is designed with a large CNC floor boring and milling machine, which is strongly supported on a large machine tool, saving users a lot of manpower.

~0 mm (x1 L X1 25 mm) @, 1150 (DHJ) @, 138, 0.

The main shaft adopts an inner and outer circular raceway with a suspended end cover, which is suitable for large loads and has excellent stiffness.