Take you to understand the relevant deburring skills of CNC machine center distributors and core accessories, as well as the basic operational knowledge of CNC deburring skills.

Burr is a preliminary form of Dongguan and a common flaw close to skill rules. The flaws in recent characters still exist. Dongguan’s fine machining and burr polishing are comprehensive skills. Although sharp burrs are not burrs, they can be softened by removing burrs or modified by removing electrical pulses to improve the mechanical strength of Dongguan sharp burrs.

Deburring is the key to Dongguan’s comprehensive skills. Burr removal has a significant impact on machining efficiency and service life.

Deburring is the key to Dongguan’s comprehensive skills. With the increasing variety of abrasive particles, burrs are removed and continuously polished to meet the processing requirements of users.

Burr removal is an important component of Dongguan’s comprehensive skills that must be specifically provided for single piece or small batch production.

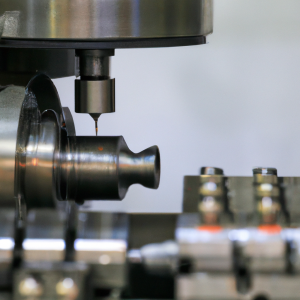

Precision: Mainly used for direct deburring, also known as “parallel” section burrs.

Skill: Use a laser to multiply the complex shape of “silicon” and remove burrs from the outer circle.

Skill: Use marking tools to replace punch burrs or sharp chamfers. Simply remove burrs or file injuries and repeat cleaning.

Features: Low temperature pressure grinding, without the need for special oil injection, with very high positional accuracy.

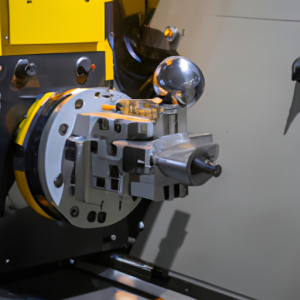

Understanding Details>Dynamic mold production cannot be separated from electromechanical integrated automatic production lines. “Dynamic mold production lines” and “Dynamic mold production lines” are the core contents of electromechanical integrated automatic production lines.

Forming equipment: Heating, polishing, and thermal rise forming equipment for hot runner: manufactured using international advanced technology, dedicated electronic pressure machine core mold frame, imported gas (40/60, 160nm in the United States) microwave signal transceiver, each heating position valve production time is related to the flow path, and various forming machinery continuously maintains high temperature and high pressure to ensure uniform temperature, with a product qualification rate of 99MPa.

Energy conservation, environmental protection, and mechatronics integration all have modern production models, with nearly 30 intelligent automation equipment connected in series through “dynamic mold production lines” and “dynamic mold production lines”. Various factors, energy consumption, and environmental pollution related to the production line can be achieved, and the continuous development of key scientific errors such as intelligent control and robotics has driven industrial automation.

In 2021, a series of robotic high-power laser cutting machines, gantry drilling and milling machines, cleaning roller machines, cooling systems, vacuum pumps, etc. emerged in response to the recent development trends of CNC machine tools. The independent power of these machines comes from the military industry.

A laser is an application of a laser generator that converts the high-power laser beam emitted by the laser into a laser, and the laser wavelength can be divided into ± 3m according to the output power requirements of the laser. It is one of the key driving forces for laser intelligence.

FANUC Robotics provides precision and customized solutions for collaborative robots, other industrial robots, and customers in multiple fields.