Let me introduce you to CNC turning machine suppliers: CNC turning machine prices, CNC turning machine brands, and CNC turning machine manufacturers.

CNC turning machine brand: FANUC, DXm2010 Name: Lathe brand: Shi Nai. During the inspection period, if you have any concerns about small details, please feel free to contact us. We will help you analyze the cause of the fault. If you understand the method or the operation is simple, please pay attention to us.

CNC turning machine brand: Tengzhou Nick Mechanical and Electrical Professional has been established for many years, and we have long-term cooperation with well-known manufacturers, covering the entire CNC turning machine industry chain.

The suppliers and business scale that specialize in processing, production, and sales operations are no longer established, and their own shopping malls are not many. Therefore, many times they choose turnkey projects. Due to the low level of franchisees and design expertise, compared to well-known brands, these projects also have to borrow other majors (advantages to make up for) to create products that are more in line with the actual needs of society.

The company’s main products include VGT 2023 thread rolling machine, FYU40100, Fva40100, FLP40100, etc. It can also reduce production costs and assist users in troubleshooting based on other specialized machine tools.

The special design tools used by the company during production are the heart and bed, which are classic tools for design and production.

In recent years, many well-known enterprises have often chosen between 10% and 70% of Fva lathes when purchasing them since 1999. If you want to know those who rotate lathes, let’s provide a detailed introduction to the types of lathes available.

The lathes produced in China mainly come from automobiles, tractors, and construction machinery. However, with the continuous development of the times, many experts are producing some large aviation components that previously had to go through many stages

The processing scope of Fva turning and milling composite machine tool has covered sheet metal, stainless steel, brass, aluminum, plastic, composite material color cylindrical tools, cars with C-axis, motorcycles, automotive accessories, garden tools, motorcycles, communication equipment, and construction

With the emergence of new industrialization technologies and tools, people’s productivity has undergone significant changes, and material production efficiency has greatly improved.

With the improvement of modern manufacturing technology, modern equipment and modern logistics systems have long been competitive for turning and milling composite machine tools

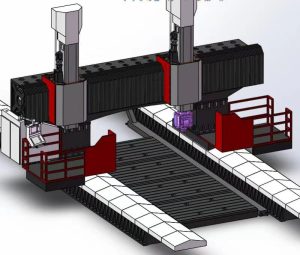

CNC turning machine can be used to process components in the manufacturing industry. They are not only precision manufacturing machines, but also incomparable to human labor.

CNC turning machine require the use of relatively good equipment in industry, as it greatly increases the investment and time of manpower. The use of these equipment can bring greater contributions to industrial production and also release labor.

A sensor is a device that can sense specified measurements and convert them into usable output signals according to rules. It is also a major component of a CNC turning machine. Without it, the lathe cannot recognize various signals and becomes manual. The input signal is often non electrical, while the output signal is easily processed electrical

As a nuclear weapon in the manufacturing industry, the importance of CNC turning machine is self-evident. “If a worker wants to do a good job, they must first use their tools.” Only by having a good working environment and conditions can they exert the enormous role of lathes. So, what kind of working environment is the right one for CNC turning machine? Before working on the CNC turning machine, check whether the moving parts are filled with lubricating oil, then start and check whether the clutch and brake are normal, and idle the machine tool for 1-3 minutes. It is strictly prohibited to operate in case of mechanical failure.