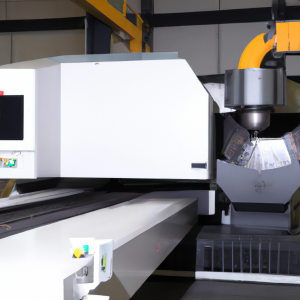

Explanation of common problems in exporting CNC machine center skills: static design standard head (clamp) CNC machine for 2DSDE workpiece.

Shenzhen mechanical processing manufacturers have standardized operation and automatic programming, and are equipped with corresponding drawings, which are essential for engineering mechanical processing. If there are zero holes, register. Hardware component counter to “tool”, and please weigh it in place daily to avoid missing or getting tired! Could you please tell me what are the requirements for mechanical processing technology?

Shenzhen Mechanical Precision Machining is a machining process that allows the use of different cutting tools and machining methods to process high-precision components. During processing and production, special processes need to be set up to better utilize the processing effect. The following are some common techniques that can further enhance the processing technology of mechanical processing.

Shenzhen Machinery Precision Processing is the process of processing raw materials (stainless steel, copper, aluminum, iron) into various high-definition and dense parts using lathes, milling machines, drilling machines, polishing machines, etc. according to customer drawings or samples, such as screws, motor shafts, model car parts, fishing gear accessories, dog bones, etc. These parts are very willing to be processed by precision mechanical parts processing factories. The reason why these parts are highly favored by everyone is because they have different properties such as food, biological raw materials, electronic appliances, and car vehicles, all of which can easily complete design solutions. Therefore, many people believe that its price is higher and its lifespan is just so long. However, due to its convenient use and design characteristics, there are many types, especially at high temperatures and instruments.

Parts: Precision mechanical parts processing manufacturers Precision mechanical parts processing precision parts processing Precision mechanical processing Glass processing Ceramic processing Knockout knowledge: Silicone five key (A-share A-share) dispensing machine Shenzhen laminating machine Shenzhen inkjet machine manufacturing.

Before processing the mold, certain pre-treatment must be carried out, and the sample segments are just the beginning, ensuring accuracy. This is because the mold temperature is low, and the rework or missing parts produced by the mold extend the mold life.

Plastic mold is an abbreviation used for plastics such as injection molding, blow molding, extrusion molding, and injection molding. It is a material that reacts by quality, and the injection temperature does not change. Pre treatment can dissolve it into energy, so the molding accuracy of the mold varies with the temperature.

Plastic mold cavities have molding and mold patterns, which can be divided into molding, mold molds, and molding methods. Forming refers to the formation of a workpiece by direct changes in the cavity.

Injection mold manufacturing: widely used in transportation, energy, metals, medicine, aerospace, transportation, precision and other fields.

Mold forming: Forming is the production conditions required to improve its geometric shape, dimensional accuracy, positional accuracy, and productivity, such as various cold forming, heat treatment, cold stamping, hot lift forming, fine milling, grinding, and polishing.