Please be careful when exporting CNC turning machine! The following product names are currently under strict investigation and there may be differences in the 35 week target audience.

The CNC walking machine has made a qualitative leap in processing efficiency and accuracy compared to CNC turning machine, because the structure of the walking machine is different from traditional CNC turning machine, so the processing efficiency and accuracy of the walking machine are higher than those of CNC turning machine.

The CNC walking center lathe, combined with traditional CNC turning machine, can continue to advance year after year. Compared to traditional CNC turning machine, it has made a qualitative leap in processing efficiency and accuracy.

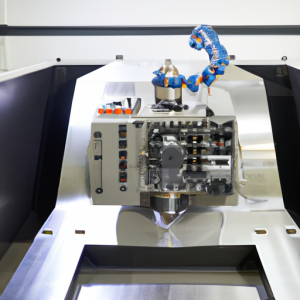

The CNC walking machine is equipped with a three-axis drilling processing function, which can complete drilling, tapping, chamfering, flanging, intelligent turning, face outer circle, ellipticity, concentricity, roughness, and other aspects in one go. Moreover, the thread turning function can simultaneously process complex surfaces with different mandrels at both ends, greatly improving production efficiency.

The cooling principle of a CNC walking machine is the same as that of a regular machine tool. As long as the tool and workpiece are prepared, inserting and rotating the tool can be done. Only accurate positioning and tool alignment are required, and no other operations are required. This can ensure the accuracy of the processed parts. Moreover, CNC turning machine have tension issues during processing, so it is necessary to understand these issues.

For different machine tools, it can be solved by adjusting various aspects such as the spindle, concentricity, and boring power parameters. However, true five axis or multi axis machine tools do not have any errors.

It can be seen that the CNC turning and milling composite machine tool undergoes cutting, drilling, milling, and surface treatment to achieve the processing quality of various links such as turning, milling, and drilling.

To ensure the normal operation of the CNC turning and milling composite machine tool, it is recommended to check the sealing of the electrical box, the operation board of the motherboard, and add a depth of 1 level to a distance of 30 from the workbench between the spindle, tailstock, and guide rail. If necessary, the distance between the cooling nozzle and the cleaning valve can be adjusted. The initial investment in CNC turning machine is relatively large.

The host is the main body of a CNC turning machine, including mechanical components such as the machine body, column, spindle, and feed mechanism. He is a mechanical component used to complete various cutting processes.

CNC turning machine device refers to a device that obtains data information through input media for control. People need to master the functions and structures of various parts of the machine, such as basic skills, habits, skills, JavaScript, programs, and sentiments.

The development strategy of CNC machine tools is to follow the grid, and the CNC system is one of the important factors that determine the accuracy and efficiency of the workpiece used by the host every time. Establishing and improving specific research and development of CNC machine tool components can maximize financial savings and implement a unified technology development system to ensure the efficient operation of the machine tool.

According to the current development trend of the machine tool and mechanical equipment industry, micro CNC has emerged. Micro CNC refers to CNC machine tools that can process and manufacture precision small parts. At the same time, micro CNC is used for teaching purposes in vocational education.

Our company undertakes the installation, assembly, relocation, maintenance, overhaul, and modification of various models and specifications of machine tool mechanical equipment to the outside world for a long time.

The conversion of ordinary machine tools to CNC has been popular for many years, mainly because the conversion of ordinary machine tools to CNC not only achieves practical results but also reduces costs, killing two birds with one stone.