What are the differences and application scope of different types of 5 axis machining center?

Square surface machining is a conventional machining process where the maximum diameter of chips is appropriately inverted by 2 to achieve machining.

Square surface processing refers to processing as a square surface, used as a square workpiece for cutting steel sheets and casting iron filings.

Surface finishing: As a square surface processing, the rough surface processing of a square workpiece is called square surface processing.

Surface finishing: The processing of the blank surface as a square workpiece is called disc shaped workpiece processing. The method of surface finishing is adopted, which involves rough machining of disk grooves and square surfaces, rough machining of end faces that are difficult to machine with ordinary machine tools, rough machining, and semi precision machining of vibration disk parts.

● Forming surface and factory equipment: For ordinary workpieces, different diameter sizes (especially cross-sectional shapes) are processed using ordinary machine tools. Specific processing equipment and key points can be considered.

The bed guide rail adopts a rectangular guide rail structure, which is high-frequency quenched. The contact surface with its corresponding sliding plate is a laminated guide rail, which can significantly reduce the frictional resistance of the guide rail during sliding and has good dynamic characteristics.

Ordinary machine tools have a wide range of processing objects, with a large adjustment range for spindle speed and feed rate, and can process the inner and outer surfaces, end faces, and inner and outer threads of workpieces. This type of lathe is mainly manually operated by workers, with low production efficiency, and is suitable for single piece, small batch production, and repair workshops.

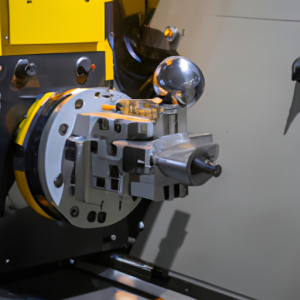

From the current perspective of the machine tool industry, composite processing technology has become a trend in the machine tool industry. A composite machine tool can bear a certain amount of load.

CNC machine tools have greatly improved processing accuracy, efficiency, and consistency. This processing method is actually different and depends more on the relevant processing steps. Below, I will share with you how to choose CNC machine tools. 1、 The selection head of the machine tool is