Boring machines are used to create precise, cylindrical holes in a variety of materials. They are used in a variety of industries, including automotive, aerospace, and construction. Boring machines come in a variety of shapes and sizes, and each type has its own unique advantages and disadvantages.

The most common type of boring machine is the vertical boring machine. This type of machine is used to create large, deep holes in materials such as steel and aluminum. The vertical boring machine is typically used for large-scale projects, such as the construction of bridges and other large structures. The vertical boring machine is also used to create large, deep holes in materials such as wood and plastic.

The horizontal boring machine is another type of boring machine. This type of machine is used to create shallow, narrow holes in materials such as wood and plastic. The horizontal boring machine is typically used for smaller projects, such as the construction of furniture and cabinets.

The jig boring machine is a type of boring machine that is used to create precise, cylindrical holes in materials such as steel and aluminum. The jig boring machine is typically used for precision work, such as the creation of engine components and other parts that require exact measurements.

The line boring machine is a type of boring machine that is used to create long, straight holes in materials such as steel and aluminum. The line boring machine is typically used for large-scale projects, such as the construction of bridges and other large structures.

The portable boring machine is a type of boring machine that is used to create precise, cylindrical holes in materials such as steel and aluminum. The portable boring machine is typically used for smaller projects, such as the construction of furniture and cabinets.

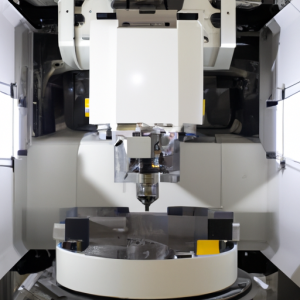

The CNC boring machine is a type of boring machine that is used to create precise, cylindrical holes in materials such as steel and aluminum. The CNC boring machine is typically used for precision work, such as the creation of engine components and other parts that require exact measurements.

The boring machine is an essential tool for many industries, and each type of machine has its own unique advantages and disadvantages. When selecting a boring machine, it is important to consider the type of project that needs to be completed, as well as the size and type of material that needs to be bored. By understanding the different types of boring machines, it is possible to select the best machine for the job.