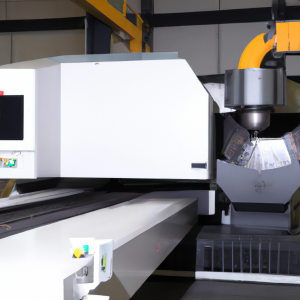

How CNC Machine Centers Can Help Streamline Your Manufacturing Process

CNC machine centers are a great way to streamline your manufacturing process. These machines are computer-controlled and can be programmed to perform a variety of tasks, from cutting and drilling to milling and grinding. With CNC machine centers, you can reduce the amount of time and labor needed to complete a job, as well as reduce the amount of scrap material produced.

CNC machine centers can be used to produce a variety of parts with precision and accuracy. They can be programmed to cut and shape materials with exact measurements, allowing for a consistent product. This eliminates the need for manual labor and reduces the amount of time needed to complete a job. Additionally, CNC machine centers can be used to produce parts with complex shapes and intricate details. This allows for a higher level of customization and can help you create unique products.

CNC machine centers also help reduce the amount of scrap material produced. By programming the machine to cut and shape materials with exact measurements, you can reduce the amount of material wasted. This can help you save money and resources, as well as reduce the amount of time needed to complete a job.

Overall, CNC machine centers are a great way to streamline your manufacturing process. They can help you reduce the amount of time and labor needed to complete a job, as well as reduce the amount of scrap material produced. Additionally, they can be used to produce parts with complex shapes and intricate details, allowing for a higher level of customization. With CNC machine centers, you can create unique products with precision and accuracy.

The Benefits of Investing in CNC Machine Centers for Your Business

Investing in CNC machine centers can provide a number of benefits for businesses. CNC (Computer Numerical Control) machine centers are computer-controlled machines that are used to create parts and components with precision and accuracy. They are used in a variety of industries, including automotive, aerospace, medical, and electronics.

The first benefit of investing in CNC machine centers is increased productivity. CNC machines are able to produce parts and components with greater accuracy and speed than manual machines. This means that businesses can produce more parts in less time, resulting in increased efficiency and cost savings.

The second benefit of investing in CNC machine centers is improved quality. CNC machines are able to produce parts and components with greater precision and accuracy than manual machines. This means that businesses can produce parts and components with higher quality, resulting in fewer defects and improved customer satisfaction.

The third benefit of investing in CNC machine centers is reduced labor costs. CNC machines are able to produce parts and components with greater speed and accuracy than manual machines. This means that businesses can reduce the number of employees needed to produce parts and components, resulting in lower labor costs.

The fourth benefit of investing in CNC machine centers is improved safety. CNC machines are able to produce parts and components with greater accuracy and speed than manual machines. This means that businesses can reduce the risk of accidents and injuries, resulting in improved safety for employees.

Overall, investing in CNC machine centers can provide a number of benefits for businesses. CNC machines are able to produce parts and components with greater accuracy and speed than manual machines, resulting in increased productivity, improved quality, reduced labor costs, and improved safety. Investing in CNC machine centers can help businesses save time and money while producing higher quality parts and components.