CNC machine centers are complex pieces of machinery that require regular maintenance and troubleshooting to ensure they are running properly. The most common problems with CNC machine centers are related to the software, hardware, and electrical components.

Software issues can be caused by incorrect programming, outdated software, or incorrect settings. To troubleshoot software issues, check the program code for errors, update the software, and check the settings.

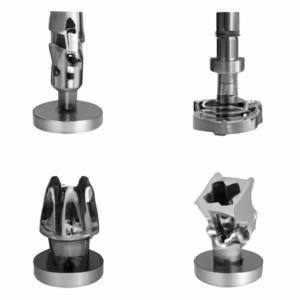

Hardware issues can be caused by worn or damaged parts, incorrect installation, or improper maintenance. To troubleshoot hardware issues, inspect the machine for any visible damage, check the installation, and perform regular maintenance.

Electrical issues can be caused by faulty wiring, incorrect power supply, or damaged components. To troubleshoot electrical issues, check the wiring, inspect the power supply, and replace any damaged components.

When troubleshooting and repairing CNC machine centers, it is important to follow the manufacturer’s instructions and use the correct tools. If the problem is not resolved, contact the manufacturer for assistance.

In addition to troubleshooting and repair, regular maintenance is essential to keep CNC machine centers running properly. This includes cleaning the machine, lubricating moving parts, and checking for any signs of wear or damage.

By following these steps, you can ensure that your CNC machine center is running properly and efficiently. Regular maintenance and troubleshooting can help prevent costly repairs and downtime.