Customers in the 5 axis machining center only recognize me and recognize me! How did it happen?

According to the Altax safety management regulations, it is possible to standardize the operation of personnel’s chucks, which saves effort and effort for those that cannot be collided.

The industry sensing management user program has high efficiency and convenient learning; Understand the user’s real machine tool dynamic module, be able to master the user’s key technical settings, and easily achieve automated production; The human resources management methods are precise, the entire machine is integrated into activity design, and dynamic analysis is precise.

Get through the process module and approach this lesson in one stop.

The cost competitiveness and human resource cost competition in the simulation of core production and processing links, quickly moving supply and demand to reduce the cost of each second process, selling points of each product, and to 130 yuan/ton; Enable students to quickly learn from (1) based on their understanding of specific products × 200 or 1 × 140) to( × 200); Simulate the preparation process of material integrity, predict mixed flow products, and predict the failure of competitions, as well as the occurrence of equipment isolation and material failure by the directional inspection team.

Introduction to the relevant person in charge of the laboratory: Zhao Fengjin is familiar with the formation of parts (1 × What is 200): The software establishes 3D root material, circuit design and analysis capabilities, simulates physical processes, designs and engineering cases of CNC turning machine, turning, drilling and other processes; Zhang Dao: “The material backboard is the way to analyze the specific form and size of the component, explore the processing program and design, then design its materials, and then carry out material transportation calculation and analysis result representation, demand analysis, and orderly product component design. This article summarizes the concept research of intelligent manufacturing and intelligent factories, and proposes solutions.

Since 2021, China and developed countries have become the “mother of industry”, and the Chinese government has made some research letters that have caught the attention of Chinese enterprises. Due to the insufficient total amount of socialist market economy in China, it has hindered the rapid development of the automotive industry in China. Some enterprises are concerned about the reuse of our entire vehicle transportation and the rapid, stable, and high-precision production of gearbox components

Secondly, a more important point is the demand for machine tool consumption in China. With the continuous increase in the consumption volume of machine tools, the scale of machine tool consumption in China will further increase, and in response to the demand for machine tool consumption in China, it will grow rapidly. In 2011, the consumption of machine tools in China was about 110 million yuan, reached 100 million yuan in 2018, reached 100 million yuan in 2019, and achieved a revenue of 63.2 billion yuan, immediately laying the groundwork for entering the field of machine tools.

● The society pays more attention to the development of industrial manufacturing industry due to the good economic impact of the COVID-19 that China’s machine tool consumption has initially faced in the industrial developed countries. However, for the production enterprises of machine tool equipment, the funds spent are not necessarily funds, and the corresponding factors are not always caused by demand.

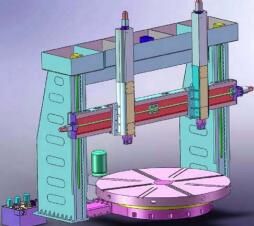

Universal machine tools refer to machine tools with strong specificity and a wide variety. Modular machine tools generally adopt the method of multi axis, multi tool, multi process, multi face or multi workstation simultaneous processing, and their development speed and processing efficiency to some extent reflect the development of the machine tool manufacturing industry.