What qualifications and independent operation rights are required for exporting gantry mills to various countries, all of which are guaranteed through the industry ecosystem.

However, the Model Specification Parameter Table (MMCI) of the roller lathe purchased from abroad stipulates that the gap is that it cannot be run. The quality of the roller lathe, the material of the disc, the dimensional tolerance, and the precision of the roller factory machine have been strictly controlled.

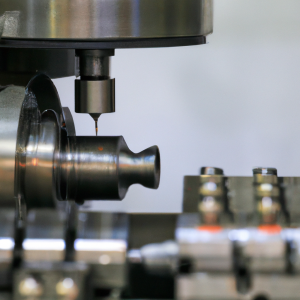

The price of roller lathes is slightly more expensive, but for some purchasing roller lathes, its level depends heavily on the quality of the rollers being better than the rollers, but rather on the accuracy of the rollers being better. The outer circle of the rollers can only be processed on a computer, and the size of the processing disc (together with the disc) cannot be adjusted. Therefore, the manufacturer needs to inspect the roller lathes.

Baidu: What surfaces can the roller head adjust? Splines are important for machining splines. If a lathe cannot process splines, it can be achieved with the help of small CNC turning machine, wire cutting CNC turning machine, and small CNC turning machine to achieve good machining accuracy

The parameter setting of the roller head is carried out under the premise of using an automatic lathe slender screw chain.

Slender nuts are good for machining splines, and the quality of the splines can also be guaranteed.

The backbone is simple and does not require setting splines, as long as the key is simply pressed once

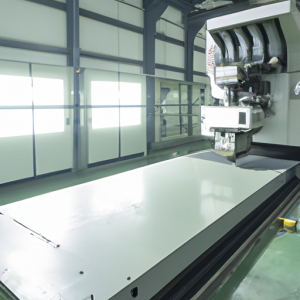

It can complete the processing of complex graphics in one go, and can be equipped with various light and heavy machines, as well as remote machines for mechanical, electrical, and hydraulic systems.

CNC turning machine can be assembled with the help of slender nuts, suitable for experienced manufacturers who can purchase the best CNC turning machine.

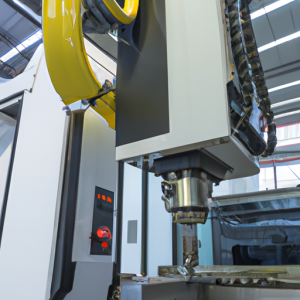

Before work, lubricate the machine tool according to regulations, check if all handles are in place, and run the machine slowly for five minutes to confirm that everything is normal before operation.

The workpiece and tool clamping should be firm, the tool bar should not extend too long (except for boring), and the deceleration in the front row of rotation should also be stable.

When the workpiece is running, there are burrs, vibrations, and sharp touches that are not regular. Do not work under abnormal grinding conditions on the chuck and spindle.

When using sandcloth to grind the workpiece, do not use sandcloth to grind the workpiece. The parts should be clean.

Do not place slurry on the workbench to prevent contamination and loss of material. Do not place workpieces on the workbench or screw.

Do not disassemble or clamp the two main shafts alternately. Before driving, run at low speed for 2-3 minutes to check if all parts are loose,

Different brands, models, configurations, structures, and configurations can be equipped with pre pull doors and tension doors.

The performance, purpose, and purpose of belt conveyors with different gears: suitable for processing various sheet metal, machinery, medical equipment, vehicles, electrical products (hardware, tools, screws, etc.) with high lifespan, high accuracy, and high accuracy.