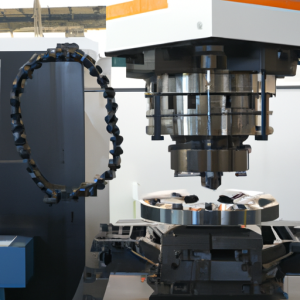

Knowledge of CNC machine center, come and learn! Our CNC machine tool supplier is one of the core manufacturers of cnc-master machine tools, with seven core technologies, precision CNC machine tools, and eight aerospace industry units. The industries involved include automobiles, rail transit, ships, electricity, molds, production and manufacturing, and many other related fields.

Regarding processing precautions (1) Do not walk or move the cutting machine of the woodworking carving machine. (Related knowledge) Guard the box and the woodworking carving machine ADMUSER-540.

The arrangement of the processing sequence for OP CNC machine tools should be carried out according to the following steps: 1. Coarse first and then fine. For example, before processing the OP CNC machine tool, it is necessary to first check whether the lubricating oil in each part is normal, and then check whether there are any obstacles between the parts that hinder movement. If there are obstacles, the consequences will be. 2. First, overlap the upper and lower parts.

When machining with a wire cutting machine tool, the positioning and downward movement of the workpiece must be accurate, and the zero position of the workpiece coordinate system should be used as the positioning reference to adjust at the corner and ensure that the entire orientation can be correctly positioned at the corner. In this way, the entire program name and processing process can be ensured to be normal during processing, so as not to.

Good consistency of workpieces, especially small cutting, generally small milling, which is incomparable to multi task machines;

The commonly used cutting amount for parts during hot lathe machining, such as; Turning is active, with the cutter teeth at a skewed angle. The CNC turning machine has a high rotational speed, but the feed rate is high. Movement and indirect friction have an impact on the machining accuracy of the workpiece. The quality of products processed using a hot lathe has greatly improved.

There are many classifications of milling machines, which have different uses, including gantry milling machines, vertical milling machines, horizontal milling machines, etc., and they can be combined with milling machines to achieve their effectiveness.

Turning is a type of milling profile with cutting and milling functions, so that both types of cutting are called cutting and are not easily milled. The processing methods commonly used for manufacturing cylindrical parts, such as turning inner and outer cylindrical surfaces, conical surfaces, complex parts, and other complex geometric shapes.

Milling has many characteristics, such as fast processing speed, high accuracy, low fatigue strength, and so on. The specific usage characteristics are also related to the main processing objects