zero setting for cnc machine

The spindle adopts Taiwan spindle

The feed motor adopts FANUC original motor

The spindle motor adopts FANUC original motor

The X-axis screw adopts the Spanish ipiranga European standard IT5 level

Y/Z axis screw adopts Japanese THK precision grinding C3 level

The guide rail adopts the silver roller P grade precision

The bearing adopts Japanese NSK precision P4 bearing

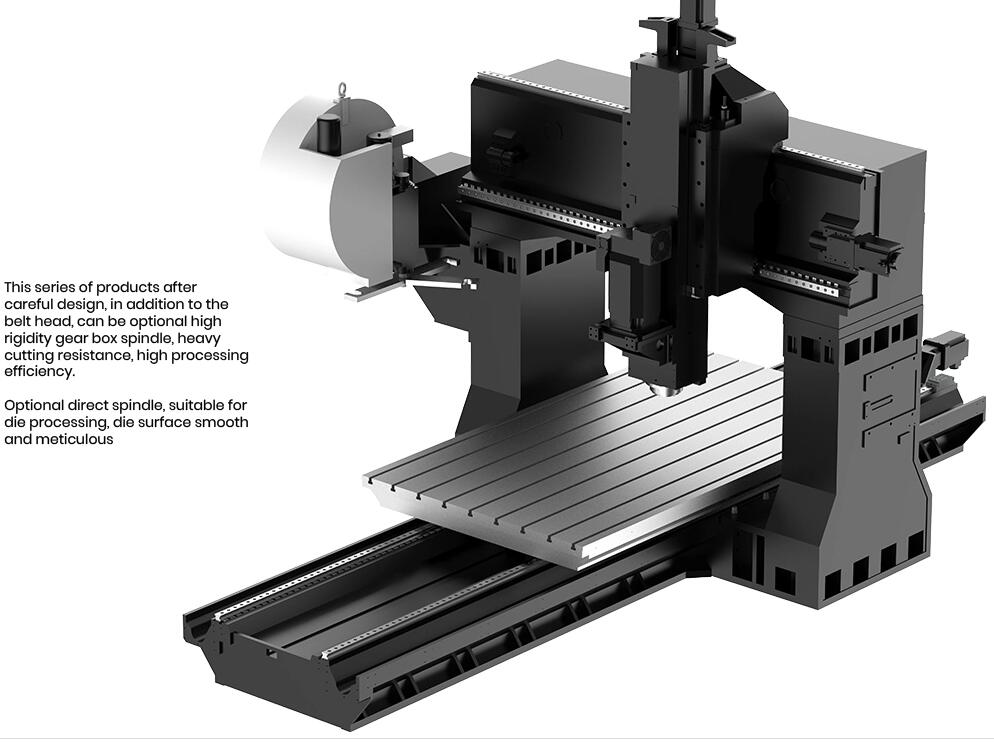

Description

Weish CNC Co., Ltd is a company that integrates the production, design, manufacturing, trade, and service of CNC machine, providing high-quality and efficient CNC machine worldwide.We can provide you with various high-quality machine tools at competitive prices. Our product has obtained CE certification.

The design and manufacture of zero setting for cnc machine comply with ISO international standards, and the units of measurement for all parts of the machine tools and various instruments all adopt international unit standards.

CNC machining of precision parts, workpiece clamping can complete drilling,reaming,milling,tapping Various processes such as silk are processed.

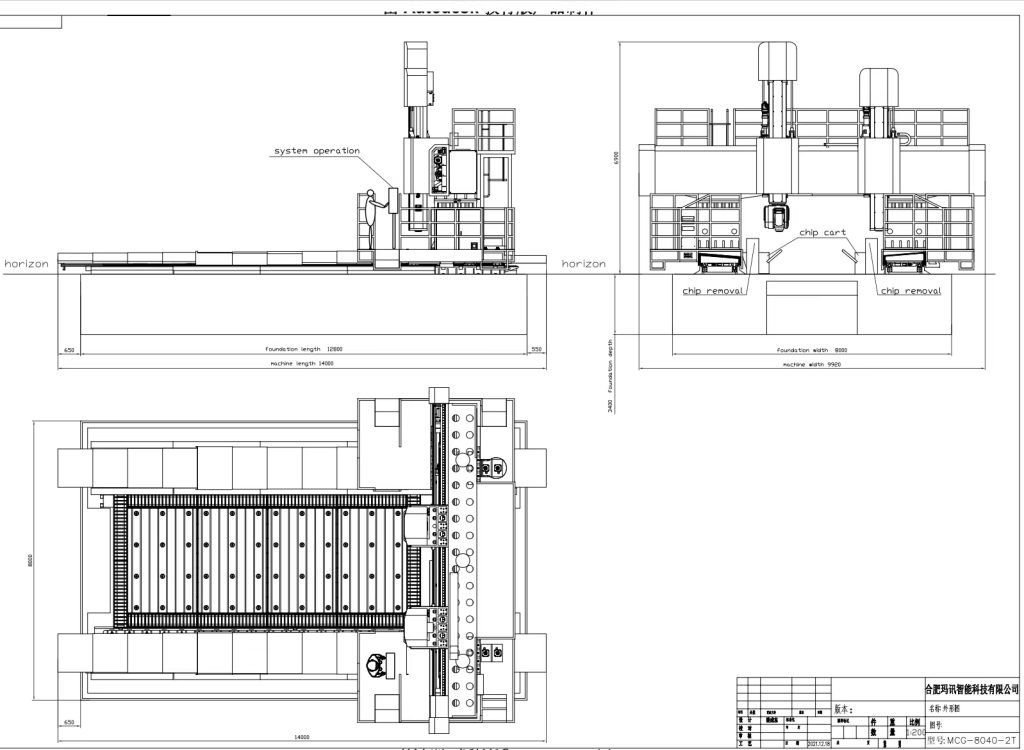

Beam: Strengthen structure. HT300

Main spindle motor: Original SIEMENS AC motor

Linear Guideway: #65

5 Axis head: MEPRO / Optional

Y1 and Y2 axis ball screw: 80mm

Bearing: FAG Germany / NSK Japan

Couping: NBK Japan

Reducing: ALPHA Germany

CNC SYSTEM:SIEMENS 840D

X.Y.Z. is 3 axis linkage controlled by system. Table moving and column fixed Cross beam moving for W axis

1:promise to replace the broken part of machine during the warranty period

2:The seller(WEISH CNC MASTER) will dispatch technicians to the customer’s designated location for installation and debugging based on customer needs. Includes Training, commissioning and programming

3:we can provide the remote training if customer don’t need the on-site installation

| Product name | zero setting for cnc machine |

| Brand Name | Weish CNC Master |

| Product Type | CNC machine |

| Place of Origin | Ningbo, Zhejiang |

| Product Size(CM) | 418*206*266(Please consult us for specific details) |

| Motor power(KW) | 21 |

| Use | molds,printing,steel…etc |

| Colors | Blue+Customizable |

| Export region | Africa,Oceania,America… |

| Export countries | Russia,India,Cyprus,Azerbaijan,Gambia…etc |

| Certification | CE |

| Feature | Recycled Materials |

| Voltage | 220V/380V |

| Services | 24 Hours Online Service |

| MOQ | 1 Set |

| Port | Ningbo |

| Packaging Details | 3×40” OT for loading |

| Lead time (days) | 25-30(To be negotiated) |

| Payment method | 30% TT prepaid.60% TT proceeding. 10% before shipment |

| Supply Ability | 30 Set/Sets per Year (See specific model products) |

Please note: This table is for reference only, please consult us for specific information.

zero setting for cnc machine–A Guide to Frequently Asked Questions

2.What are the after-sales services available for zero setting for cnc machine?

3.How does the zero setting for cnc machine ensure the safety of operators?

4.What is the research and development capability of the factory?

5.What is the main structure and structure of zero setting for cnc machine?

6.What is the general power of the zero setting for cnc machine spindle?

7.Where is your factory located? How can I visit there?

8.About zero setting for cnc machine, what are your payment terms?

9.Does the zero setting for cnc machine have a cooling system to control temperature?

10.zero setting for cnc machine manufacturer service and quality system

1.How many axes does zero setting for cnc machine device typically have?

3 axis , 3+2 axis, 5 axis. Up to client’s reqirement

2.What are the after-sales services available for zero setting for cnc machine?

Two-year warranty, Seller should assign 2 or 3 engineers come to clinet’s site for installation.

3.How does the zero setting for cnc machine ensure the safety of operators?

Our company has many years of zero setting for cnc machine experience and expertise.The CNC machine has several safety features in place to ensure the safety of operators.

1. Emergency Stop Button: The machine is equipped with an emergency stop button that immediately stops all operations in case of an emergency.

2. Safety Protective Covers: The machine has safety guards and covers around moving parts to prevent operators from coming into contact with them.

3. Interlocks: The machine has interlocks in place to prevent the machine from starting if any doors, covers, or protective guards are open.

4. Soft Limit Switches: CNC machines have soft limit switches that limit the range of motion of the machine, preventing it from hitting the end of its travel and causing damage or harm.

5. Warning Signs: The machine has warning signs and labels to alert operators to potential hazards and safety precautions.

6. Emergency Override: In case of a malfunction or emergency, the machine can be manually overridden to stop its operations.

7. Safety Sensors: Some CNC machines have safety sensors that automatically detect the presence of someone in the work area and stop the machine to prevent accidents.

4.What is the research and development capability of the factory?

Independently researched and developed, pioneering new research and development technology, and equipped with mature production capabilities,series gantry machining centers have always prioritized efficiency, high precision, and high rigidity, providing you with extremely powerful chip cutting capabilities. With more flexible options and a more complete series of specifications, it is widely used in various fields such as the automotive industry, precision molds, aerospace industry, military shipbuilding industry, etc.

5.What is the main structure and structure of zero setting for cnc machine?

The gantry frame of the zero setting for cnc machine is composed of two columns, beams, sliding saddles and other components. According to the gantry frame, the gantry machining center can be a fixed beam type, a moving beam type and a moving column type gantry machining center. The beam of the top beam gantry machining center is fixed and the workbench moves; the beam of the moving beam gantry machining center moves up and down, and the workbench moves forward and backward; the workbench of the moving column gantry machining center is fixed and the gantry moves.

6.What is the general power of the zero setting for cnc machine spindle?

Usually 37-55KW

7.Where is your factory located? How can I visit there?

Our factory is located in Ningbo City ,Zhejiang Province,China. You are warmly welcomed to visit us.

8.About zero setting for cnc machine, what are your payment terms?

30% TT prepaid.60% TT proceeding. 10% before shipment

9.Does the zero setting for cnc machine have a cooling system to control temperature?

Yes. Lubricate system. Cutting oil temp control system

10.zero setting for cnc machine manufacturer service and quality system

WEISH CNC MASTER has a highly skilled and experienced R&D team that can carry out customized design and manufacturing according to customer needs. The company’s products adopt advanced numerical control systems and electronic control systems, which have the advantages of high precision, high stability, and high efficiency. In addition, the company also has a complete after-sales service system that can provide customers with a full range of technical support and services.

Tags:touch probes for cnc machines,cnc wood carving machines,cnc machine working,heavy cnc machining,cnc machine plastic,cnc machine rotary table