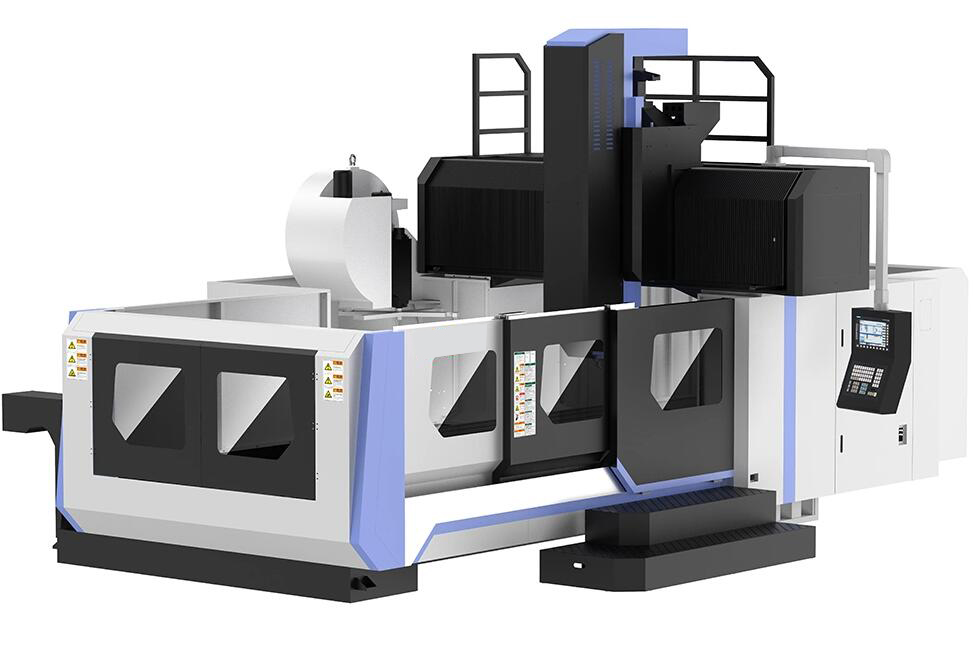

cnc milling machine manufacturers

We make this type customerized up to our clients

Description

CNC milling machine manufacturers produce a variety of milling machines for precision machining tasks in various industries. Provide a series of milling machines, including five axis milling centers and universal milling machines, for high-precision machining. Widely used in manufacturing and processing applications.

| Item | Name | Brand | Remark | ||||

| 1 | ATC | OKADA TAIWAN | Optional | ||||

| 2 | Feeding motor | FANUC | X axis 36NM two double drives, YZ axis torque 36NM, Z axis with brake | ||||

| 3 | Main motor | FANUC | 22/26KW | ||||

| 4 | System | FANUC OIMF | |||||

| 5 | X-Screw | Ipiranga Spain | IT5 | ||||

| Y/Z Screw | THK | C3, | |||||

| 6 | Bearing | NSK | P4 | ||||

| 7 | Electric part | ||||||

| 8 | Leaner guideway | HIWIN Taiwan | 55 rollers | ||||

| 9 | encoder | Absolute encoder | No need to return to the origin | ||||

| 10 | Guideway | HIWIN Taiwan | 55 roller | ||||

| 11 | Main spindle | MicroLab Taiwan | |||||

| Item | |||||||

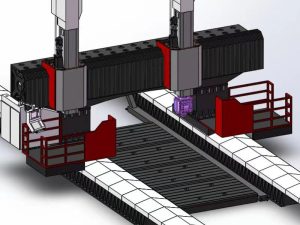

| 1 | X travel | mm | 12000 | ||||

| 2 | Y travel | mm | 4400 | ||||

| 3 | Z travel | mm | 1200 | ||||

| 4 | Between column | mm | 4200 | ||||

| 5 | Distance from spindle end to worktable | mm | 600-1800 | ||||

| 6 | Worktable size | mm | 8000*3000 | ||||

| 7 | Max loading | T | 8/M2 | ||||

| 8 | T slot | No. | 28 | ||||

| 9 | T-slot size/spacing | mm | 28/250 | ||||

| 10 | Spindle drive mode | Direct drive | |||||

| 11 | Spindle speed | rpm | 10-6000 | ||||

| 12 | Motor power | kW | 22/26 | ||||

| 13 | Spindle torque | N.m | 170+BFGear box 680NM | ||||

| 14 | Spindle taper | ISO7:24NO50 | |||||

| 15 | Pull nail specifications | P50T-2-MAS503 | |||||

| 16 | Spindle dia | mm | Φ190 | ||||

| 17 | X、Y、Z Rapid move | m/min | 7/7/7 | ||||

| 18 | X、Y、Z servo motor | kW | 5.2*2/5.2/5.2 | ||||

| 19 | X、Y、Z servo torque | N.m | X-36*4,YZ-36*3/36*3 | ||||

| 20 | X、Y、Z servo motor | rpm | 3000 | ||||

| 21 | X/Y/Z Dia of Screw | mm | Φ10020/8020/Φ6320 | ||||

| 22 | Feeding speed | mm/min | 6000 | ||||

Tag: cnc milling machine manufacturers

CNC Milling Machine Manufacturers: Innovations in Precision Machining

CNC milling machine manufacturers innovate in precision machining through various means to improve machine tool performance and processing efficiency.

1. The manufacturer adopts advanced CNC systems with stronger processing capabilities and more intuitive interfaces, making operations simpler while providing higher machining accuracy.

2. Use a high-speed spindle to increase cutting speed, reduce processing time, and improve surface quality and workpiece accuracy.

3. Develop new tool technologies, including high hardness tools and coated tools, to improve wear resistance and cutting performance.

4. Manufacturers develop cutting fluids to improve cooling and lubrication performance, reduce tool wear, and improve machining quality.

5. Introduce automation systems, such as automatic tool change systems and automatic workpiece loading and unloading systems, to improve production efficiency.

6. Manufacturers provide more 5-axis CNC milling machines to achieve more complex part processing, reduce clamping times, and improve accuracy.

7. Use simulation software to allow operators to simulate and validate programs before actual machining, reducing errors and improving efficiency.

8. Search for lighter and more robust machine tool structural materials to reduce the quality of the machine tool, improve stability and rigidity.

You must be logged in to post a review.

Reviews

There are no reviews yet.