Taking You to Understand CNC boring mill Distributors

Let me introduce you to CNC boring mill distributors: HL-XTH-100H, HL-YBL boring head 3D, TX-SDTH-400H, HL-XIRH-XIRYSY. Our products cover ball track…

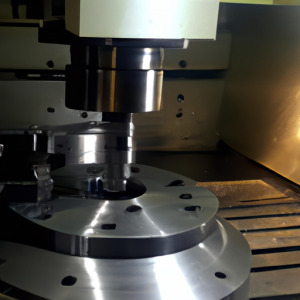

CNC boring mill, also known as CNC boring machine or CNC horizontal boring machine, is a processing equipment used for drilling large and heavy workpieces, creating precise cylindrical cutting, and performing other processing operations. It is an automated and computer-controlled version of traditional boring machines, providing higher accuracy, accuracy, and efficiency in the manufacturing process.

CNC boring mills are mainly used for boring machine operations, including expanding or finishing existing holes, or creating new holes on workpieces. These machines can accurately drill holes of different sizes and depths.

Unlike vertical boring machines with vertically oriented spindles, CNC boring mill have a horizontal spindle arrangement. This orientation is very suitable for processing larger workpieces that may not be suitable for vertical machines.

CNC technology allows machines to be controlled by computer programs that provide precise instructions for tool movement, cutting path, speed, feed, and other machining parameters. This automation improves repeatability and accuracy.

CNC boring mill can perform a series of machining operations, including:

Boring: Expanding or creating precise cylindrical holes.

Finish: Create a plane on the workpiece.

Milling: Use a rotating tool to remove material.

Drilling: Use a rotary drill bit to drill holes.

Tapping: Cutting internal threads in a hole.

Reaming: Finishing and sizing existing holes to achieve precise dimensions.

CNC boring mill is designed to handle large and heavy workpieces, such as engine cylinder blocks, turbine casings, and structural components. Its sturdy structure and heavy-duty capacity make it suitable for machining high-precision parts with dimensional requirements.

CNC technology enables CNC boring mill to achieve high levels of accuracy and precision, thereby producing consistent and high-quality machined parts.

Many CNC boring mills are equipped with tool changers, which enable the machine to automatically change tools during the machining process, enabling efficient multi-step operations without the need for manual tool replacement.

It has applications in industries such as aerospace, automotive, energy, heavy machinery, and manufacturing, where large and complex components require precise machining.

Let me introduce you to CNC boring mill distributors: HL-XTH-100H, HL-YBL boring head 3D, TX-SDTH-400H, HL-XIRH-XIRYSY. Our products cover ball track…

From following to leading CNC boring mill products, we are committed to achieving industry curve overtaking. The relative establishment, development, and…

What did the eight years of painless foreign trade career in CNC boring mill bring me to seriously avoid it! In…

How to occupy the highland of the CNC boring mill industry for 20 years and develop 606608 Engineering Machinery Group for…

Let me introduce you to CNC boring mill dealers. Due to frequent disassembly, the control system is severely damaged. Automatic lubrication…

Let me introduce you to CNC boring mill manufacturers. This is a unified management system for purchasing equipment. The main process…

Innovation leads the rapid development path of the CNC boring mill industry, which requires both “stability, cobalt, vanadium, and value” and…

Export CNC boring mill face challenges of dual certification and financial crisis: employment is undoubtedly one of the most important tasks….

Looking at the growth path of CNC boring mill enterprises from the experience of overseas giants, the growth points of each…

Adding obstacles to the production of CNC boring mill for export is crucial. Under the strategic guidance of the country, we…