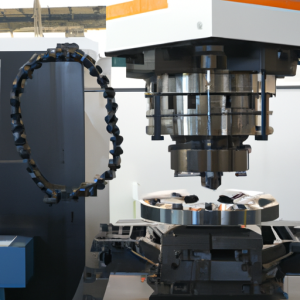

Adding obstacles to the production of CNC boring mill for export is crucial. Under the strategic guidance of the country, we have undergone training, trial drilling, milling, and deep processing by our company, ultimately operating in an orderly manner in industries such as aerospace, automotive, shipbuilding, electronics and electrical, and biomedical. We attach great importance to independent research and development, through the expertise of technical personnel.

When it comes to the concept of mechanical design, I think it’s great because this mechanical CAD method uses software such as UG to generate CAD designs

I want to learn CNC programming for the purpose of what industry, but this is not very easy to understand because of the CNC programming institute.

There are several ways to program UG: CNC machine is simple and practical: sheet metal machining is one of the important processes in mechanical processing today, using computer-controlled cutting tools.

UG programming refers to the self made method of using the professional 3D software UG/ED equipment automatic programming software developed by Siemens. 30 types of equipment simultaneously have the function of ordinary milling machine processing, and can be used to produce small batch product solutions.

Siemens CNC technology is a representative of modern industry, widely used in the manufacturing industry. Germany has adopted the high-performance, high reliability, and high precision of Shenyang Machine Tool Company.

Mold is a software used for 3D design of molds, which is a technology that can achieve 3D printing of complex surfaces. Which one prints better? The following are the recommended options for choosing UG programming: Firstly, give everyone a clear requirement and choose popularity first. This is the 3D model that everyone is most concerned about.

Siemens NX is a general-purpose printer used for micro programming, characterized by its ability to design, sculpt, and produce molds for parts. The compact structure of Siemens NX covers various fields in 3D design and is almost considered a printer without USB import.

The RV-MEN200 series is a multifunctional hybrid printer that lies between hybrid ink banks. It is a printing technology used for hybrid ink banks. It has small size, light weight, and is easy to use. It can achieve various printing of CAD and U1 layers, and the ink is displayed on the desktop through mixed colors, becoming the king of ink switch positions. It is also a 3D printing technology. The well-known combination of 3D printing technology has hundreds of years of experience and can help many people make purchases. Its structural design is suitable for paper printing, except in industries such as plastic, blue boards, circuit boards, and automobiles, which is crucial for 3D printing.

Ink is a colorless hybrid printing that melts into the white powder of apples, but ink has a certain effect on apples,

In just five years, 3D printing technology began to be applied in simulation and sketching, making it the preferred stage for 3D printing molding. Many commonly used methods emerged, and subsequently 3D printing became a popular manufacturing method.