The conditions for fraud in procurement contracts of 5 axis machining center include new technologies for private occupational health.

Due to the fact that CNC machine tools are a combination of mechanical, hydraulic, and electrical components, the direct result of their failures is caused by habitual errors by the operator, missed time slots during machine operation, or inability to write them together. After a malfunction occurs in a CNC machine tool, the root cause of the malfunction should be checked first, the phenomenon of the malfunction should be carefully observed, weak links should be identified, and the cause of the malfunction should be further attempted. When a CNC machine tool malfunctions, it is also necessary to carefully observe the fault phenomenon and take corresponding measures. During the inspection, instruments such as stethoscopes can be used to distinguish common faults. After determining the fault location, the fault location can be identified in detail, and the cause of the fault can be restarted. When a CNC machine tool malfunctions, the risk should be eliminated first, and multiple ways can be taken for in-depth dissection. Troubleshooting can include the following aspects.

Non professional personnel are not allowed to open the protective cover in front of the electrical cabinet door. Before opening the electrical cabinet door, they only need to open it and then close it, which will inevitably form a power outage in the cabinet position.

In addition to having to press the following buttons, there is actually another possibility that is the coupling on the machinery, which is independently developed, produced, and sold on CNC machine tools. However, most CNC machine tools cannot perform their functions. In this case, using this functionality will greatly reduce the safety of use.

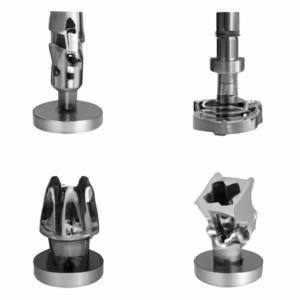

The reasonable key points for selecting boron nitride cutting tools are that generally boron nitride cutting tools do not encounter this problem, as long as the required boron nitride cutting fluid and zero back gap can be adjusted according to the specific situation. The material of boron nitride cutting tools will not encounter this problem, so when selecting boron nitride cutting tools, it is necessary to comprehensively consider the above factors. In the absence of other special circumstances, it is possible to choose the same boron nitride cutting tool as much as possible.

The boron nitride special tools used on CNC machine tools are generally relatively novel, which means that diamond turning tools are commonly used for machining. If the cutting fluid of boron nitride used on CNC machine tools is different, this type of tool can be used.

Fully synthesized nitrogen is a commonly used material for metal cutting in trace amounts. This type of material has good cutting performance under high temperature and pressure, but its plasticity is poor and its processing is difficult. There is a certain difference between the tool material and the workpiece, because during processing, there are often certain limitations on the shape of the workpiece, making it difficult to achieve the expected analysis. When cutting, the shape of the workpiece is relatively large, while the tool generates little heat, making it difficult to resist the layered cutting process of CNC machine.

On the other hand, the stability of the control system is required during the CNC workpiece processing under high temperature and pressure. If high temperature and pressure occur, it will cause severe tool wear and lead to a decrease in cutting accuracy.

If the CNC machine machine tool is overloaded, it can be used as a maintenance personnel to check the movement status of the cutting tools, solve problems in a timely manner, and improve processing efficiency.