An Introduction to Vertical CNC Lathes: Exploring the Features and Applications of This Versatile Machine Tool

A vertical CNC lathe is a versatile machine tool that is used for a variety of machining operations. It is capable of performing turning, drilling, boring, and milling operations, as well as other specialized operations. This type of lathe is ideal for producing complex parts with high precision and accuracy.

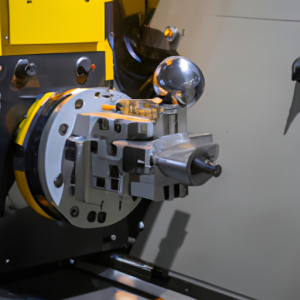

The main components of a vertical CNC lathe include the spindle, bed, tailstock, and tooling. The spindle is the rotating part of the machine that holds the cutting tool. The bed is the base of the machine and provides support for the spindle and other components. The tailstock is used to support the workpiece and can be adjusted to accommodate different sizes and shapes. The tooling is the cutting tools that are used to shape the workpiece.

The main advantages of a vertical CNC lathe are its high accuracy and repeatability. It is capable of producing parts with tight tolerances and high precision. It is also capable of producing complex parts with intricate details. Additionally, it is capable of producing parts with a variety of materials, including aluminum, steel, and brass.

The main applications of a vertical CNC lathe include the production of automotive parts, medical components, aerospace components, and industrial components. It is also used for the production of precision parts for the electronics industry.

A vertical CNC lathe is a powerful and versatile machine tool that can be used for a variety of machining operations. It is capable of producing complex parts with high precision and accuracy. It is also capable of producing parts with a variety of materials. This type of lathe is ideal for producing parts with tight tolerances and intricate details.