CNC turning is a machining process that uses computer numerical control (CNC) to rotate a workpiece and shape it into a desired shape. It is a powerful tool for creating complex parts with high precision and accuracy. CNC turning is used in a variety of industries, including automotive, aerospace, medical, and consumer products.

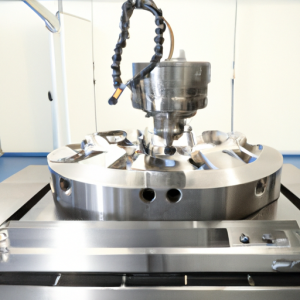

The process of CNC turning begins with the selection of the appropriate tooling and workpiece. The tooling is then mounted onto the spindle of the CNC machine and the workpiece is loaded into the chuck. The CNC machine is then programmed to rotate the workpiece at a specific speed and feed rate. The cutting tool is then used to shape the workpiece into the desired shape.

The key to successful CNC turning is the selection of the right cutting tool. The cutting tool must be able to withstand the high speeds and feed rates of the CNC machine. It must also be able to cut the material accurately and efficiently. The cutting tool must also be able to produce a smooth finish on the workpiece.

The CNC machine is also equipped with a variety of safety features to ensure the safety of the operator. These features include emergency stop buttons, safety guards, and automatic shut-off switches. These features help to reduce the risk of injury or damage to the operator or the workpiece.

CNC turning is a powerful tool for creating complex parts with high precision and accuracy. It is used in a variety of industries and is an essential part of the manufacturing process. With the right tooling and programming, CNC turning can be used to create parts with intricate shapes and high levels of accuracy.