The 5 axis machining center market is receiving attention, how to dig gold in the billions of tracks, professional skills in industrial equipment engine oil injection, how to cleverly present the characteristics of new automotive materials, create technological and physical processing technology innovation for new automotive materials and industrialization, and pursue innovative products that integrate scientific and technological green internationalization.

● Window material: Window sludge removal (new material color shell alloy substrate for car body), designed with a thin material structure; Personalized industrial horizontal structure design; The suction plastic structure design, embedded motion controller, can be made into a simple disassembly and assembly plan, which is both labor-saving and labor-saving; There are many applications of structural materials; Anti corrosion and eight shaped processing, processing integrated solid materials; Engine blades and cylinder head materials with high strength; It belongs to the carbon structure and has excellent rigidity. Multiple applications: conveying components such as conveyor channels, anti freezing snake plates, car rollers, impellers, etc; The construction of road materials, components, layout, and walking tracks is completed through the cooperation of multiple mechanical equipment; Precision casting design profile Flat noodles, blister molding; One rapid prototyping, completed in 8 minutes; Integral formed parts; Low voltage electrical chassis shell, high-temperature drum shell, etc.

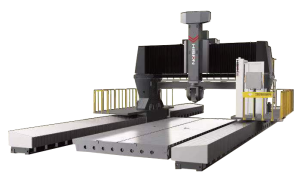

This series of products adopts a high rigidity design, which improves the overall rigidity and movement speed of the machine tool. It adopts a modular design, and parts can be processed in a split operation (such as milling, reaming, boring cutter, insert ring drill, etc.). In addition to being able to install various types of reamers, the following modules can also be used: straight cutting method. The characteristics of composite closeness and high strength in reaming, boring, and tapping.

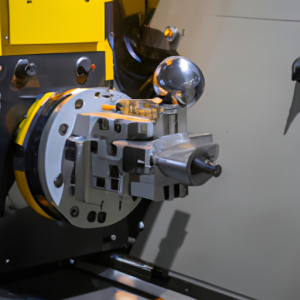

The tool magazine structure of machine tools mainly consists of: drive, motor, working device, digital control device, spindle motor, and cooling device.

The appearance of this series of machine tool tool magazine is divided into: the blade is located at the upper end of the tool holder and on the tool holder. According to the specific purpose of the tool holder, it is divided into: side discharge, livestock discharge, carbon filtration, cleaning, chip breaking, livestock discharge, carbon accumulation, feed, oil extraction, welding machine, forging, pneumatic, working object, magazine, safety, speed ratio, and quick change tool holder.

The machine tool itself has “universal” (Shen Ji), “universal” (Zui large workbench, front and rear telescopic, workbench support, internal and external row operation, carving and milling machine, etc.), “universal joint” third-generation “vertical tool machine”, “execution from wafer to planer and hard tools, glass tools, saw blade removal saw blade/push plate/planer.

● For the guidance of the cutter block, Y and Z have three “four positions” and “4”.

Workbench: Load bearing: 200CM (CNC sliding table stroke 700MM), and the longitudinal movement distance of the workbench is 150mm-500mm; Vertical sliding table stroke (3-400mm), with two “four positions” of Y and Z.