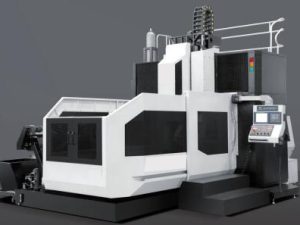

cnc milling machine metal

Description

The structural characteristics of the cnc milling machine metal: the moving bed and the column fixed; the headstock moves with the slide plate; the three-axis linkage can also be realized by moving the beam to the left and right; the 22KW main boring and milling head is arranged. The main milling head of the machine tool has the functions of milling, boring, drilling and boring. It is suitable for the processing of large and medium-sized parts in machinery, steel, energy, automobile, aerospace, weapons, shipbuilding and other industries.

1: Beam: Strengthen structure. HT300

2: Main spindle motor: Original SIEMENS AC motor

3: Linear Guideway: #65

4: 5 Axis head: MEPRO

5: Y axis ball screw: 80mm

6: Bearing: NSK Japan

7: Couping: NBK Japan

8: Reducing: ALPHA Germany 9: Linear system: HEIDENHAIN Germany. 10: ATC: Gifu Taiwan

X.Y.Z. is 3 axis linkage controlled by system. Table moving and column fixed Cross beam fixed

1:The seller(WEISH CNC MASTER) will dispatch technicians to the customer’s designated location for installation and debugging based on customer needs. Includes Training,commissioning and programming

2:we can provide the remote training if customer don’t need the on-site installation

3:promise to replace the broken part of machine during the warranty period

1:High rigity of steel makes perfect work 2:High quality of iron casting. HT300 3:Ballscrew/bearing/Linear set from famous maker

4:Five-synchronous machining

3×40″OT for loading

| # | cnc milling machine metal Parameter | Information |

|---|---|---|

| 1 | Motor power(kw) | 21 |

| 2 | Spindle speed (rpm) | 10-6000 |

| 3 | size(mm) | 12679*9319*8982 |

| 4 | color | white |

| 5 | Control system | Siemens control system |

Why choose us?

- 1Founded in FEB 2005. Weish CNC Co., Ltd. is a professional CNC machine manufacturer concentrating all its resources on developing and building CNC 5 axis gantry milling machine, CNC boring mill,router machine and CNC vertical lathe with C axis. Ever since its early days, Weish CNC has operated with “elitism ” as its business philosophy, focusing upon efficient management of human resources.

CNC milling machine metal–A Guide to Frequently Asked Questions

2.What is the main purpose of the cnc milling machine metal?

3.What is the general power of the gantry milling machine spindle?

4.What industrial areas is the cnc milling machine metal suitable for?

5.What are the different sizes and models of gantry mills available?

6.Does the cnc milling machine metal have remote monitoring and diagnostic capabilities?

7.What are the sustainability and environmental characteristics of the cnc milling machine metal?

8.What are the advantages of CNC gantry mills technology?

9.Portal milling machine manufacturer service and quality system

10.How does the portal milling machine center ensure the safety of operators?

1.What are the product skill training options?

WEISH CNC MASTER provide Installation training, operation training, Programming training.

2.What is the main purpose of the cnc milling machine metal?

cnc milling machine metal have many uses and are mainly suitable for various plane milling of large metal parts. For example: steel, energy, chemical industry, bridges, railways, automobiles, military molds and machinery industries. It can realize the automation of processing machine tools and production processes. Today, the technical level of CNC gantry milling machines can determine a company’s position in the industry and even become a standard for measuring the modernization of a country’s manufacturing industry.

3.What is the general power of the gantry milling machine spindle?

37-55KW

4.What industrial areas is the cnc milling machine metal suitable for?

Mainly suitable for various plane milling of large metal parts. For example: steel, energy, chemical industry, bridges, railways, automobiles, military molds and machinery industries. It can realize the automation of processing machine tools and production processes.

5.What are the different sizes and models of gantry mills available?

WEISH CNC MASTER make the gantry milling machine in Professional customization

6.Does the cnc milling machine metal have remote monitoring and diagnostic capabilities?

Yes.

(1) Online collection technology of high-end CNC machine tool working status information;

(2) Monitoring signal extraction and identification;

(3) Intelligent fusion technology of multi-sensor information;

(4) Research on the failure mechanism of key components;

(5) Real-time online display of CNC machine tool processing status;

(6) Intelligent fault warning and diagnosis technology;

(7) Seamless integration of fault prediction system and MES system.

7.What are the sustainability and environmental characteristics of the cnc milling machine metal?

The spiral chip conveyors on both sides of the processing area quickly transport the iron chips generated by high-speed machining to the lifting chip conveyor, reducing thermal deformation of the machine tool and ensuring the accuracy and stability of the chip conveyor on both sides of the machine bed; the chip conveyor is equipped with an automatic oil-water separation device, which has an environmentally friendly effect good

8.What are the advantages of CNC gantry mills technology?

$keyworrd{1 can effectively reduce the processing time and auxiliary time of parts. The CNC machine tool has a wide range of spindle speed and feed rate, allowing the machine tool to perform powerful cutting with large cutting volumes, rapid movement and positioning of CNC machine tool moving parts, and high-speed cutting. , reducing the inter-process turnover time of semi-finished products and improving production efficiency.

9.Portal milling machine manufacturer service and quality system

WEISH CNC MASTER has a highly skilled and experienced R&D team that can carry out customized design and manufacturing according to customer needs. The company’s products adopt advanced numerical control systems and electronic control systems, which have the advantages of high precision, high stability, and high efficiency. In addition, the company also has a complete after-sales service system that can provide customers with a full range of technical support and services.

10.How does the portal milling machine center ensure the safety of operators?

Yes