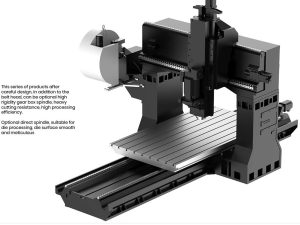

cnc metal mill

Description

CNC metal mill are mobile table CNC gantry boring and milling machines. On the basis of inheriting the advantages of traditional gantry machine tool basic frame rigidity, structural symmetry, and strong stability, it introduces Japan’s advanced dynamic rigid design concept. It has the characteristics of high precision, high rigidity, strong vibration absorption, good stability, good dynamic characteristics, large torque and heavy cutting.

The machine tool has various 2D and 3D high-speed and high-precision processing functions such as milling, boring, drilling inner holes, outer circles, planes, steps, cones, spherical surfaces, and grooves. The machine tool’s technical indicators and configuration are domestically leading, its product structure and technology are mature, and its product quality is stable. Widely used in various mechanical processing fields such as energy, aerospace, automobile, printing, textile, packaging, transportation, military industry, hardware and rubber, and molds.

The design and manufacture of cnc metal mill comply with ISO international standards, and the units of measurement for all parts of the machine tools and various instruments all adopt international unit standards.

1: Beam: Strengthen structure. HT300

2: Main spindle motor: Original SIEMENS AC motor

3: Linear Guideway: #65

4: 5 Axis head: MEPRO

5: Y axis ball screw: 80mm

6: Bearing: NSK Japan

7: Couping: NBK Japan

8: Reducing: ALPHA Germany 9: Linear system: HEIDENHAIN Germany. 10: ATC: Gifu Taiwan

X.Y.Z. is 3 axis linkage controlled by system. Table moving and column fixed Cross beam moving for W axis

1:The seller(WEISH CNC MASTER) will dispatch technicians to the customer’s designated location for installation and debugging based on customer needs. Includes Training,commissioning and programming

2:we can provide the remote training if customer don’t need the on-site installation

3:promise to replace the broken part of machine during the warranty period

1:High rigity of steel makes perfect work 2:High quality of iron casting. HT300 3:Ballscrew/bearing/Linear set from famous maker

4:Five-synchronous machining

| # | cnc metal mill Parameter | Information |

|---|---|---|

| 1 | Motor power(kw) | 22 |

| 2 | Spindle speed (rpm) | 10-6000 |

| 3 | size(mm) | 17614*9833*6082 |

| 4 | color | Standard Grey |

| 5 | Control system | Fagor control system |

Why choose us?

- 1Founded in FEB 2005. Weish CNC Co., Ltd. is a professional CNC machine manufacturer concentrating all its resources on developing and building CNC 5 axis gantry milling machine, CNC boring mill,router machine and CNC vertical lathe with C axis. Ever since its early days, Weish CNC has operated with “elitism ” as its business philosophy, focusing upon efficient management of human resources.

cnc metal mill–A Guide to Frequently Asked Questions

2.What are the maintenance requirements for the gantry milling machine

3.Does the gantry milling machine device have an automated loading and unloading system?

4.What are the dimensions and load-bearing capacity of the workbench of the gantry milling machine?

5.Does the cnc metal mill have an automatic measurement and calibration system?

6.Does the cnc gantry milling machine have an automatic tool replacement feature?

7.What are the sustainability and environmental characteristics of the cnc metal mill?

8.What are the different sizes and models of gantry mills available?

9.How many axes does cnc gantry milling machine center device typically have?

10.What is the general power of the gantry milling machine spindle?

11.What are the advantages of CNC gantry mills technology?

12.Does this gantry milling machine have a tool monitoring system?

13.Does the portal milling machine center support multi tasking?

1.How does the portal milling machine center ensure the safety of operators?

Yes

2.What are the maintenance requirements for the gantry milling machine

1. External maintenance: Maintain the internal and external surfaces of the machine tool. When changing products for processing, clean the work surface as appropriate, and check and repair burrs at any time.

2. Keep the spindle and tool magazine clean. Check the tool magazine when turning on the machine. The spindle needs to run at low speed for 10 minutes before starting work.

3. Knife handles and knife sheaths are neatly arranged and rust-proof. Check that the screws should not be loose or rough.

4. Keep the appearance of the computer clean and dust-free. Clean up junk files and organize folders at any time. File naming must include information such as (name, version, time, operator).

5. Keep the electric control box clean and dust-free.

6. Lubricating oil Check the oil level in the oil pool, which requires the lubricating mechanism to have good performance, safety and reliability.

7. Fixed beam CNC gantry milling machine coolant eliminates leakage and blockage.

8. The air duct and air gun should be kept unobstructed and there should be no air leakage.

9. Keep tool boxes and tables clean inside and outside, neatly arranged, and workpieces protected from rust.

10. Keep the shelves clean, tidy and rust-proof.

3.Does the gantry milling machine device have an automated loading and unloading system?

Yes. Robot

4.What are the dimensions and load-bearing capacity of the workbench of the gantry milling machine?

Table size is Up to client’s requirement. Worktable loading is from 30-150 Tons

5.Does the cnc metal mill have an automatic measurement and calibration system?

cnc metal mill adopts a modular design and can provide customers with different configurations according to specific needs, including on-machine measurement of workpiece contour thickness, 3D precision automatic calibration, online workpiece monitoring, chain tool magazine, and online monitoring; optional high-performance Siemens system and autonomous controllable CNC systems.

6.Does the cnc gantry milling machine have an automatic tool replacement feature?

Our machine can be equiped with ATC for tools and ATC for milling head

7.What are the sustainability and environmental characteristics of the cnc metal mill?

The spiral chip conveyors on both sides of the processing area quickly transport the iron chips generated by high-speed machining to the lifting chip conveyor, reducing thermal deformation of the machine tool and ensuring the accuracy and stability of the chip conveyor on both sides of the machine bed; the chip conveyor is equipped with an automatic oil-water separation device, which has an environmentally friendly effect good

8.What are the different sizes and models of gantry mills available?

WEISH CNC MASTER make the gantry milling machine in Professional customization

9.How many axes does cnc gantry milling machine center device typically have?

3 axis , 3+2 axis, 5 axis. Up to client’s reqirement

10.What is the general power of the gantry milling machine spindle?

37-55KW

11.What are the advantages of CNC gantry mills technology?

$keyworrd{1 can effectively reduce the processing time and auxiliary time of parts. The CNC machine tool has a wide range of spindle speed and feed rate, allowing the machine tool to perform powerful cutting with large cutting volumes, rapid movement and positioning of CNC machine tool moving parts, and high-speed cutting. , reducing the inter-process turnover time of semi-finished products and improving production efficiency.

12.Does this gantry milling machine have a tool monitoring system?

Yes. ARTIS system monitoring

13.Does the portal milling machine center support multi tasking?

Yes. Five facing machining, 5 axis machining. 3+2 axis machining.