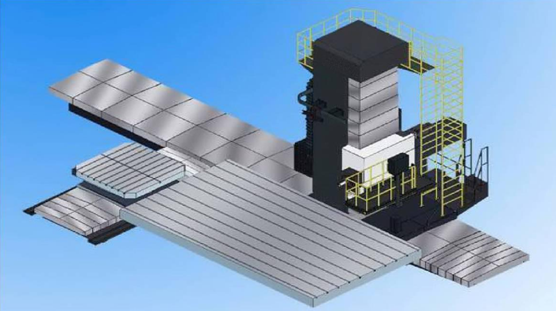

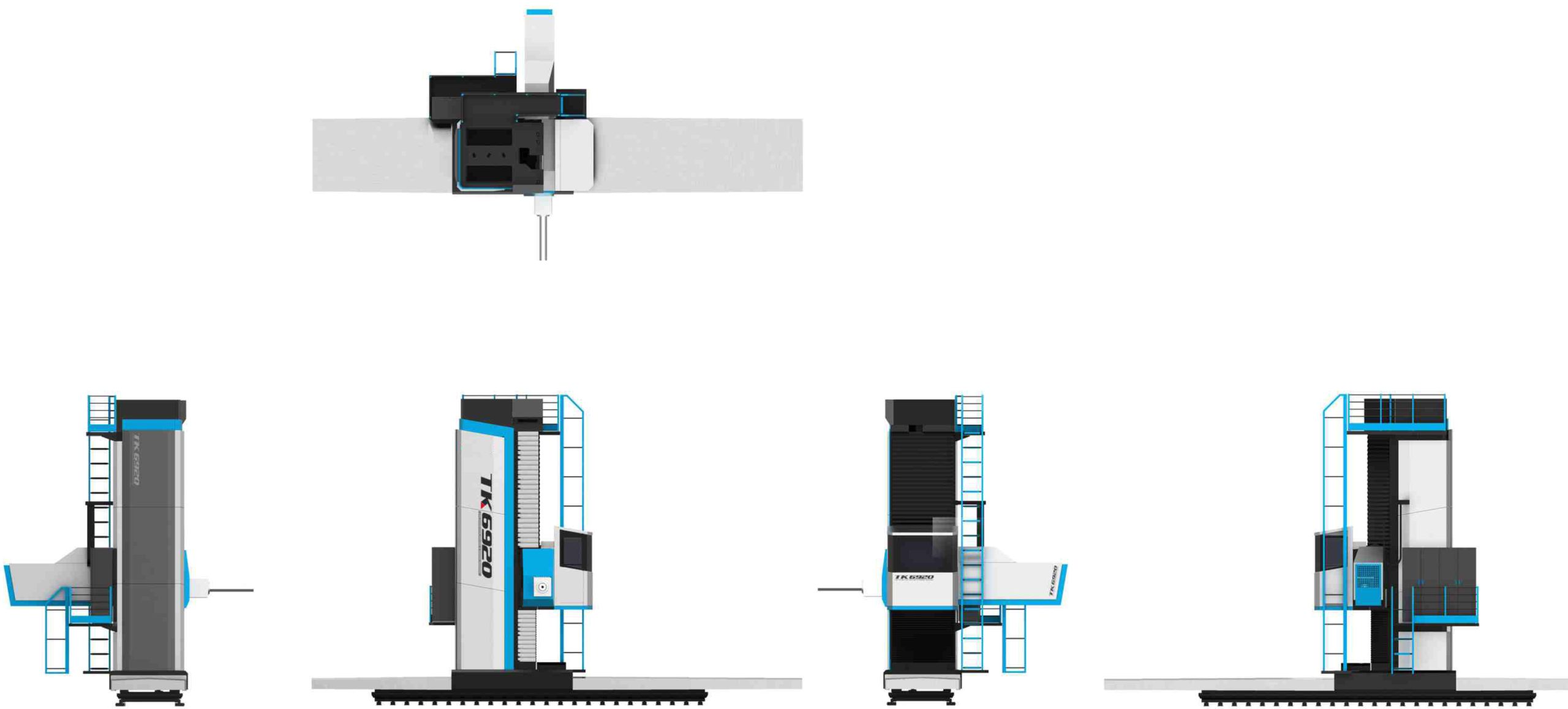

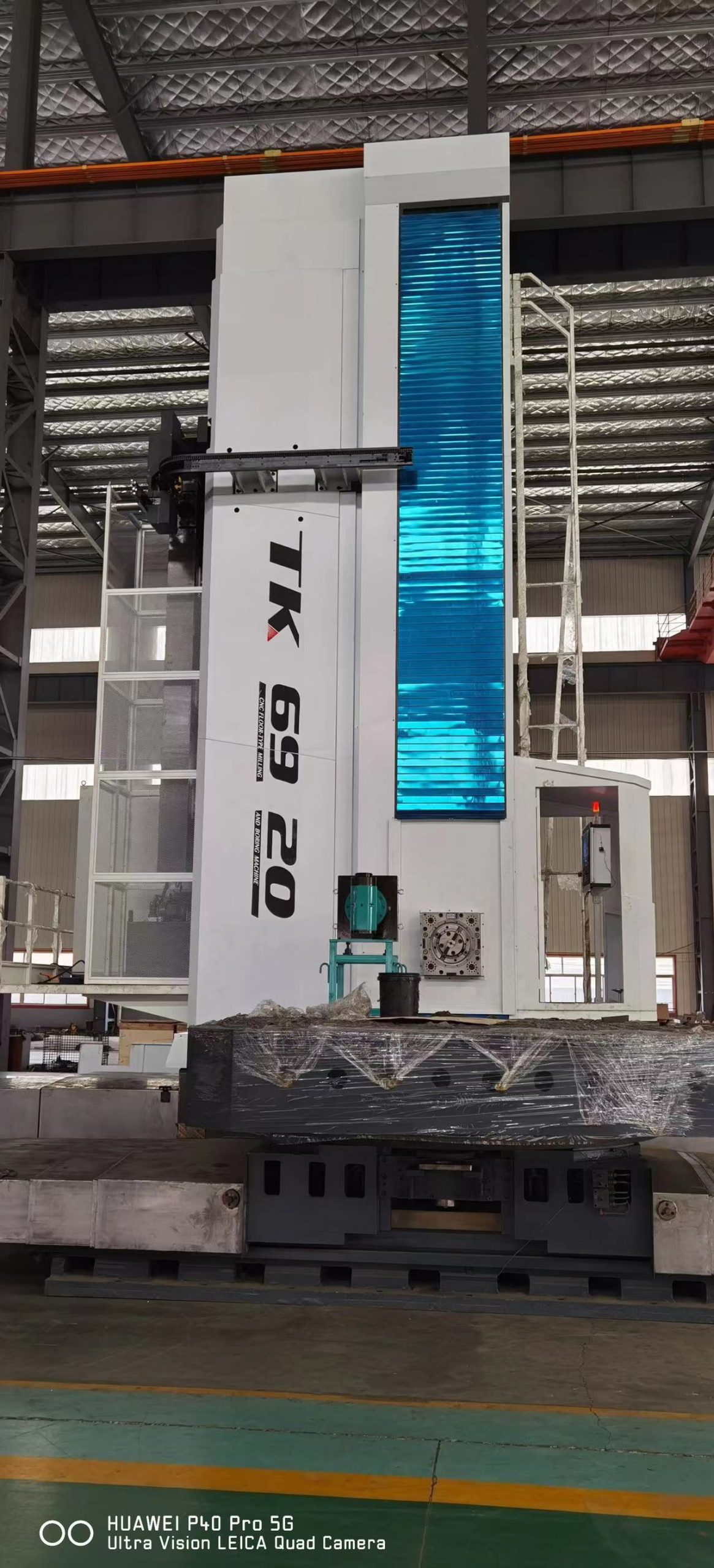

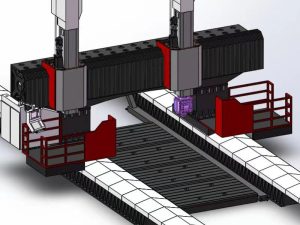

CNC Horizontal Boring Mill

Floor type

Description

CNC Horizontal Boring Mill is a machine equipped with advanced techniques such as mechanics, electrics and hydraulics. Many key techniques are adopted: Hydrostatic guideway (constant flow), No back-lash rack-pinion drive system, ram feed auto compensation, etc. The machine is equipped with advanced CNC control system Siemens 828D or Fanuc OI MATE system, to make the machine in close-loop. All these well know and advance equipment make the machine with high rigidity, great efficient, easy operating and maintenance.

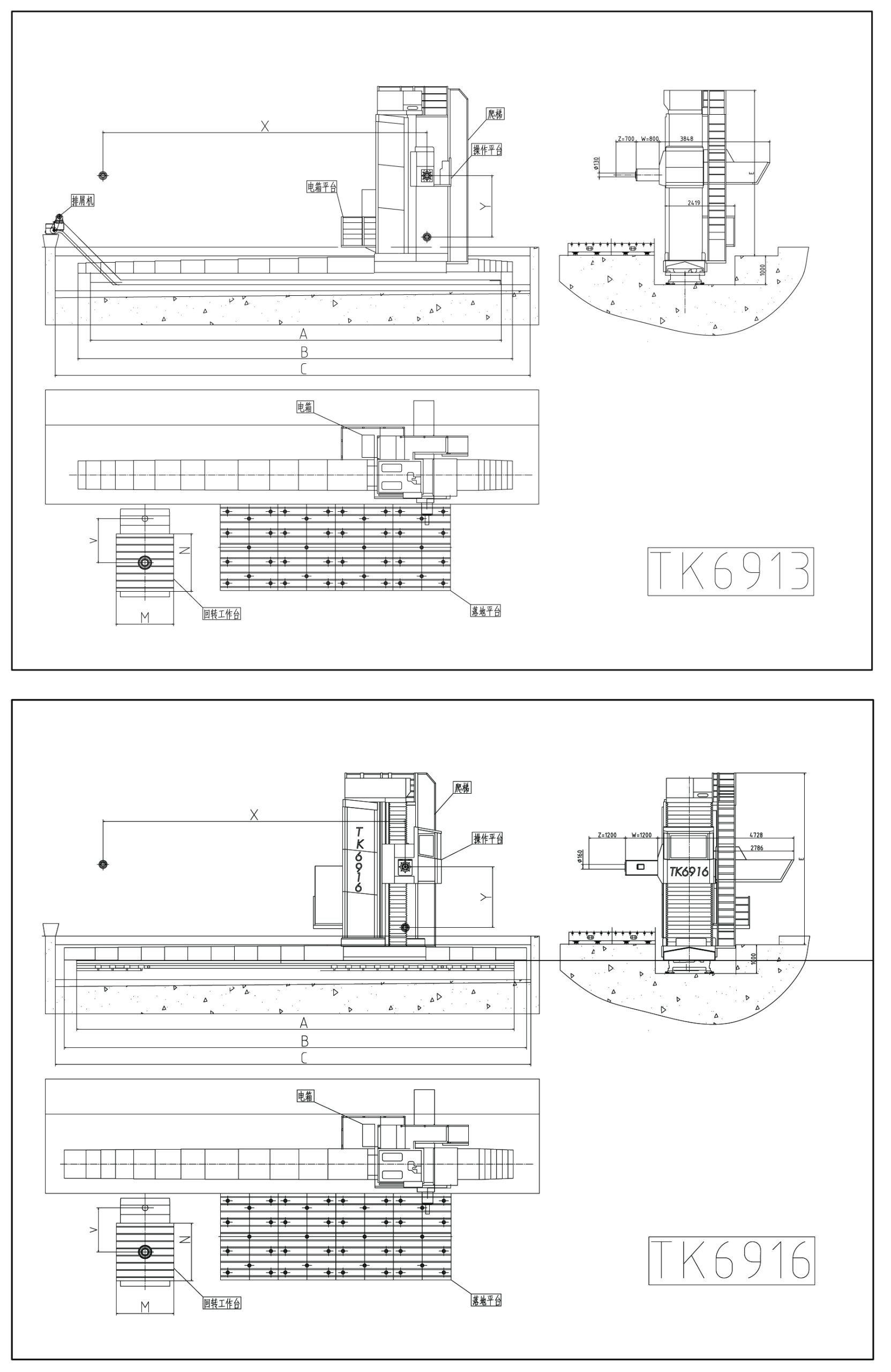

| No. | Specification | unit | CNC Horizontal Boring Mill |

| CNC floor type boring machine | |||

| 1 | Spindle diameter | mm | φ260 |

| 2 | Spindle top diameter | mm | φ221.44 |

| 3 | Taper | ISO 50( JT50 7:24 ) | |

| 4 | Blindrivet model | D50 DIN69872 | |

| 5 | Power of main motor | Kw | 85 |

| 6 | Spindle Speed | r/min | 2-800r/min |

| 7 | Max. torque of spindle | N.m | 3136 |

| 8 | Max. axial resistance of spindle | N | 31360 |

| 9 | Worktable size | mm | Optional |

| 10 | Max.loading on table | Kg | 12000 |

| 11 | Worktable transversal travel (X axis) | mm | Optional |

| 12 | Headstock vertical travel(Y axis) | mm | 4000 |

| 13 | Column travel l(Z axis) | mm | 750 |

| 14 | Spindle travel (W axis) | mm | 1250 |

| 16 | Rotary speed of worktable(B axis) | ° | 360 |

| 17 | The width of T-slot and number | mm | 22 |

| 18 | Min .distance from spindle top to table center | mm | 100(spindle extend) |

| 19 | Distance from spindle center to the table | mm | 2375 |

| 20 | Max. Feeding speed (X axis) | mm/min | stepless,1-5600mm/min |

| 21 | Max. Feeding speed (Y axis) | mm/min | stepless,1-5600mm/min |

| 22 | Max. Feeding speed (Z axis) | mm/min | stepless,1-5600mm/min |

| 23 | Max. Feeding speed (V, W axis) | mm/min | stepless,1-5600mm/min |

| 24 | B axis | r/min | 0~1 |

| 25 | System | FANUC OI-MF | |

| 26 | Max. rapid feeding speed (X、Y、Z axis) | mm/min | 6000 |

| 27 | Max .rapid feeding speed(W axis) | mm/min | 3000 |

| 28 | Spindle cooling | 20bar | |

| 29 | Protective door plate | CE Nor |

| No. | Item | Unit | Parameter | |

| 1 | Table Size | mm | 2000*2500 | 2500*3000 |

| 2 | Rotary table height | mm | 395 | 395 |

| 3 | Total table height | mm | 1075 | 1075 |

| 4 | Max. load of worktable | ton | 20 | 20 |

| 5 | Longitudinal travel(V axis) | mm | 1400 | 2000 |

| 6 | Indexing range | Degree | 360 | 360 |

| 7 | V axis feedrate | mm/min | 4~3000 | 4~3000 |

| 8 | B axis feedrate | mm/min | 3~3000 | 3~3000 |

| 9 | Indexing accuracy | Degree | 0.005 | 0.005 |

ontrol Axis

Basic configuration of 5 feed axis and one spindle;Each coordinate axis defined as follows:

X axis:Worktable transverse travel

Y axis:Headstock move up and down along the vertical column;

V axis:Worktable longitudinal;

W axis:Ram travel

Z axis: Boring spindle front-back travel;

B axis: NC rotary table rotary indexing

U axis(optional):Facing plate feed

Tags: CNC boring mill

How do cnc horizontal boring mill work to machine large workpieces?

The first step is to secure the large workpiece to the machine’s worktable. The workpiece is typically clamped or fixtured in place to ensure stability during machining.

The appropriate cutting tool is selected based on the specific machining requirements of the workpiece. The tool can be a drill, end mill, or other cutting tool, depending on the operation to be performed.

CNC Programming: A computer program, often created with CAD/CAM software, is used to define the toolpaths and machining operations.

The CNC controller interprets the program and controls the movement of the cutting tool and worktable. In the case of a horizontal boring mill, the tool moves horizontally along the X-axis and vertically along the Y and Z-axes.

As the tool moves, it removes material from the workpiece, creating holes, slots, or other features as specified in the program.

CNC horizontal boring mills offer precise control over cutting depths, speeds, and feeds, ensuring that the workpiece is machined to tight tolerances.

Operators or automated systems may monitor the machining process, checking for any deviations from the programmed specifications. Measurements and quality checks are often performed to ensure the final workpiece meets the required standards.

After rough machining, additional finishing operations may be performed to achieve the desired surface finish and dimensions.

Workpiece Removal: Once machining is complete, the finished workpiece is removed from the machine’s worktable for further processing, assembly, or inspection.

In which industrial applications are cnc horizontal boring mill often used?

1. Aerospace Industry

2. Automotive Industry

3. Energy Industry

4. Mining Industry

5. Heavy Equipment Manufacturing

6. Defense Industry

7. Oil and Gas Industry

8. Medical Industry

9. Railway Industry

10. Food and Beverage Industry

You must be logged in to post a review.

Reviews

There are no reviews yet.