cnc machining solutions

The spindle adopts Taiwan spindle

The feed motor adopts FANUC original motor

The spindle motor adopts FANUC original motor

The X-axis screw adopts the Spanish ipiranga European standard IT5 level

Y/Z axis screw adopts Japanese THK precision grinding C3 level

The guide rail adopts the silver roller P grade precision

The bearing adopts Japanese NSK precision P4 bearing

Description

WEISH CNC MASTER specializes in the design, development, production, and sales of CNC machine. We have established a world leading standard workshop and multiple automated production lines. Passed the ISO quality management system and environmental management system, and obtained multiple product certifications such as CE. Our machines have been exported to Russia, India, South Africa, Vietnam, Peru, the United States, and Tajikistan,Vietnam,etc.

The design and manufacture of cnc machining solutions comply with ISO international standards, and the units of measurement for all parts of the machine tools and various instruments all adopt international unit standards.

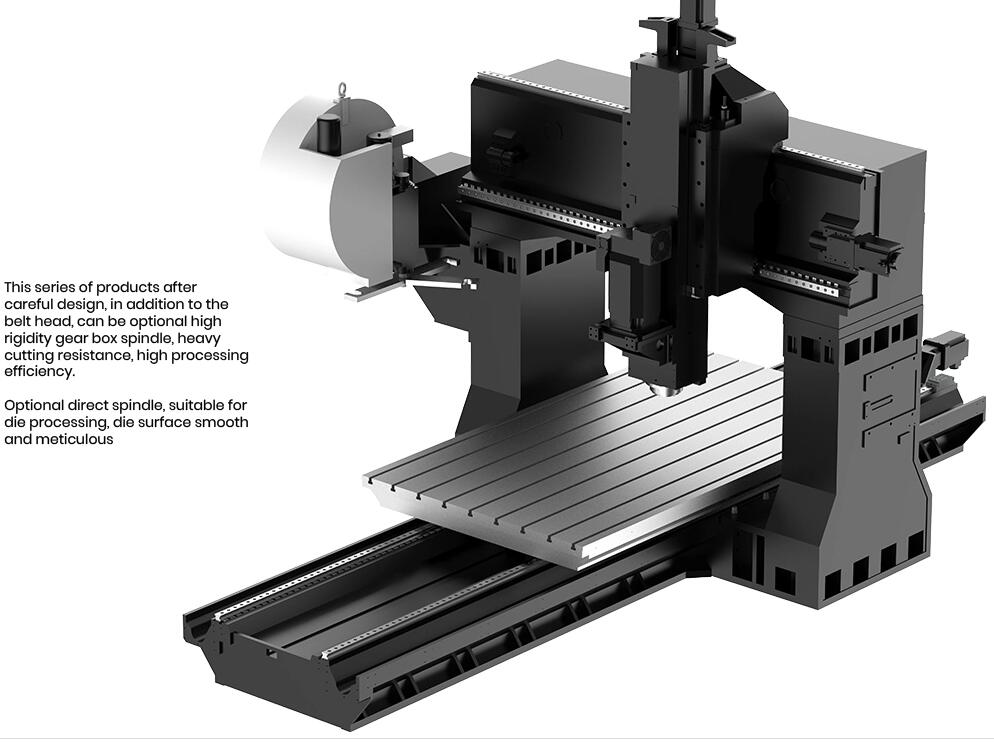

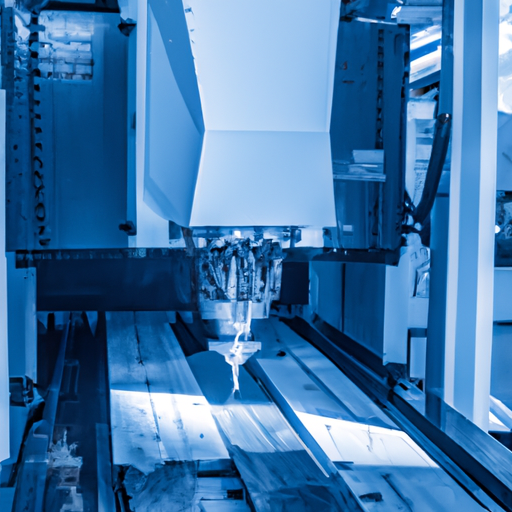

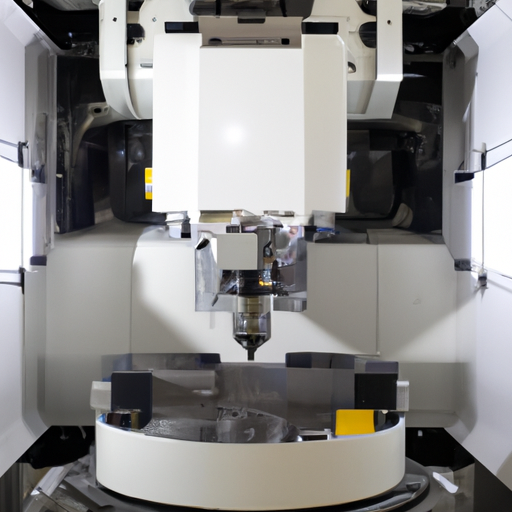

CNC machining of precision parts, workpiece clamping can complete milling,reaming,boring,drilling Various processes such as silk are processed.

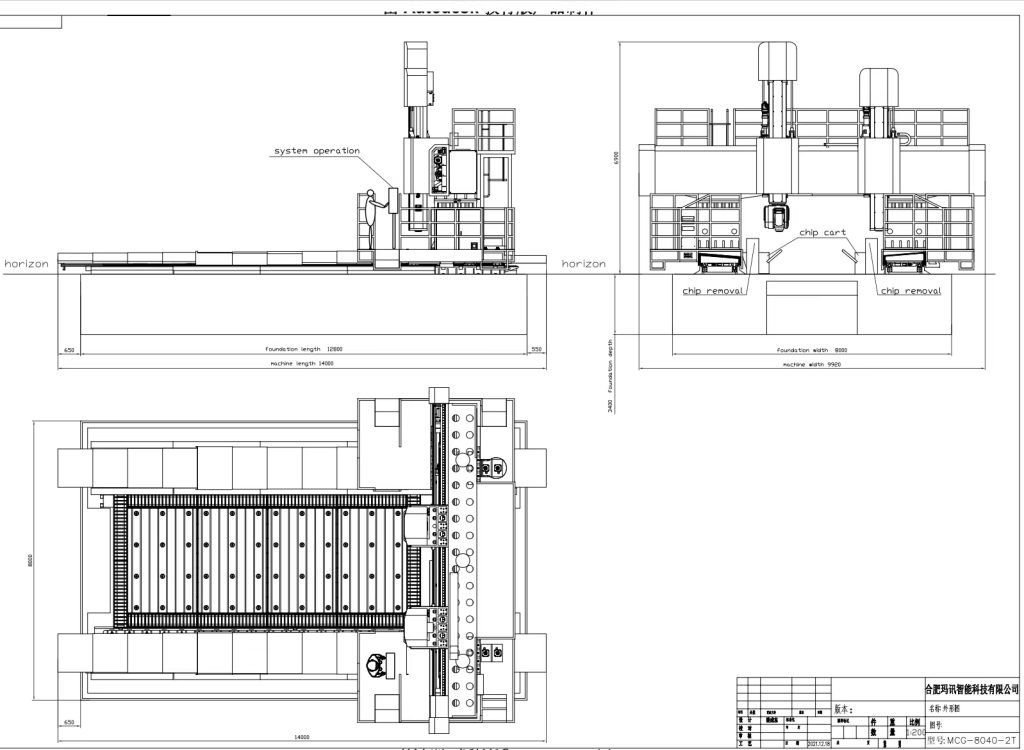

Beam: Strengthen structure. HT300

Main spindle motor: Original SIEMENS AC motor

Linear Guideway: #65

5 Axis head: MEPRO / Optional

Y axis ball screw: 80mm

Bearing: FAG Germany / NSK Japan

Couping: NBK Japan

Reducing: ALPHA Germany

Linear system: HEIDENHAIN Germany.

ATC: Gifu Taiwan

CNC SYSTEM: SIEMENS/FANUC

X.Y.Z. is 3 axis linkage controlled by system. Table moving and column fixed Cross beam fixed

1:The seller(WEISH CNC MASTER) will dispatch technicians to the customer’s designated location for installation and debugging based on customer needs. Includes Training, commissioning and programming

2:we can provide the remote training if customer don’t need the on-site installation

3:promise to replace the broken part of machine during the warranty period

| Product name | cnc machining solutions |

| Brand Name | Weish CNC Master |

| Product Type | CNC machine |

| Place of Origin | China |

| Product Size(CM) | 627*199*278(Please consult us for specific details) |

| Motor power(KW) | 23 |

| Use | automobile,weapons,steel…etc |

| Colors | Standard Grey+Customizable |

| Export region | Asia,America,Oceania… |

| Export countries | Russia,India,Qatar,Peru,Estonia…etc |

| Certification | CE |

| Feature | Recycled Materials |

| Voltage | 220V/380V |

| Services | 24 Hours Online Service |

| MOQ | 1 Set |

| Port | Ningbo |

| Packaging Details | 3×40” OT for loading |

| Lead time (days) | 25-30(To be negotiated) |

| Payment method | 30% TT prepaid.60% TT proceeding. 10% before shipment |

| Supply Ability | 30 Set/Sets per Year (See specific model products) |

Please note: This table is for reference only, please consult us for specific information.

cnc machining solutions–A Guide to Frequently Asked Questions

2.About cnc machining solutions,What’s the MOQ?

3.What is the working noise level of the cnc machining solutions?

4.R&D direction of cnc machining solutions manufacturers industry

5.About cnc machining solutions,What is the delivery time?

6.What is cnc machining solutions and how does it work?

7.What are the security features of cnc machining solutions?

8.About cnc machining solutions,Do you have any certificates?

9.What is the main purpose of the cnc machining solutions?

10.What are the product skill training options?

1.Does this cnc machining solutions have a tool monitoring system?

Yes. ARTIS system monitoring

2.About cnc machining solutions,What’s the MOQ?

1 set. We will offer you’re a better price if you order more.

3.What is the working noise level of the cnc machining solutions?

Our CNC machine’s working noise is less than 70DB

4.R&D direction of cnc machining solutions manufacturers industry

Modularization, specialization and personalization of CNC gantry milling machine, Networking and integration of CNC gantry milling machines, Opening up of CNC gantry milling machines.

5.About cnc machining solutions,What is the delivery time?

The full series of standard models are in stock. For a customized one, it depends.

6.What is cnc machining solutions and how does it work?

It is an automated machine tool equipped with a program control system. The control system can logically process programs with control codes or other symbolic instructions, decode them, express them with coded numbers, and input them into the numerical control device through the information carrier. After calculation and processing, the CNC device sends out various control signals to control the movement of the machine tool and automatically process the parts according to the shape and size required by drawing.

Working Principle When using a CNC machine tool, the geometric information and process information of the drawings of the parts to be processed must first be written into a processing program using the prescribed code and format; then the processing program is input to the CNC device, and the CNC system information is processed according to the requirements of the program. , distribution, so that each coordinate moves a certain minimum displacement amount to realize the relative movement of the tool and the workpiece to complete the processing of the part.

7.What are the security features of cnc machining solutions?

Automatic power-off,Full loop protection, Crush detective system

8.About cnc machining solutions,Do you have any certificates?

Yes, our machine is CE-compliant, and our factory is ISO 9001 accredited.

9.What is the main purpose of the cnc machining solutions?

cnc machining solutions have many uses and are mainly suitable for various plane milling of large metal parts. For example: steel, energy, chemical industry, bridges, railways, automobiles, military molds and machinery industries.

It can realize the automation of processing machine tools and production processes. Today, the technical level of CNC gantry milling machines can determine a company’s position in the industry and even become a standard for measuring the modernization of a country’s manufacturing industry.

10.What are the product skill training options?

WEISH CNC MASTER provide Installation training, operation training, Programming training.

Tags:prototype cnc machining georgia,cnc grinding machine,chip conveyor for cnc machine,file for cnc machine,cnc plasma cutting machine