The use of precision CNC machine centers has revolutionized the manufacturing industry, allowing for greater accuracy and efficiency in the production of parts and components. In this blog post, we will explore how precision CNC machine centers can help boost productivity and quality in the manufacturing process. We will discuss the advantages of using precision CNC machine centers, the types of machines available, and the benefits of investing in a precision CNC machine center. Finally, we will look at how precision CNC machine centers can help manufacturers achieve their goals of increased productivity and quality

The use of precision CNC machine centers has revolutionized the manufacturing industry, allowing for greater accuracy and efficiency in the production of parts and components. With the ability to produce parts with exacting precision, CNC machine centers have become an invaluable tool for manufacturers looking to increase productivity and quality.

The advantages of using precision CNC machine centers are numerous. CNC machines are capable of producing parts with a high degree of accuracy and repeatability, reducing the need for manual labor and eliminating the possibility of human error. Additionally, CNC machines are able to produce parts with complex geometries and intricate details that would be impossible to achieve with traditional machining methods. This allows manufacturers to produce parts with greater complexity and precision, resulting in higher quality products.

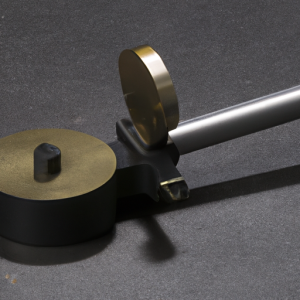

There are a variety of CNC machine centers available, each designed to meet the specific needs of the manufacturer. From 3-axis machines to 5-axis machines, there is a CNC machine center to suit any application. Additionally, CNC machines can be programmed to produce parts with a variety of materials, including metals, plastics, and composites.

Investing in a precision CNC machine center can provide manufacturers with a number of benefits. CNC machines are capable of producing parts with greater accuracy and repeatability, resulting in higher quality products. Additionally, CNC machines are able to produce parts with complex geometries and intricate details that would be impossible to achieve with traditional machining methods. This allows manufacturers to produce parts with greater complexity and precision, resulting in higher quality products.

Finally, CNC machines are able to produce parts with greater speed and efficiency, resulting in increased productivity. By reducing the need for manual labor and eliminating the possibility of human error, CNC machines can help manufacturers achieve their goals of increased productivity and quality.

In conclusion, precision CNC machine centers are an invaluable tool for manufacturers looking to increase productivity and quality. With the ability to produce parts with exacting precision, CNC machines are capable of producing parts with greater accuracy and repeatability, resulting in higher quality products. Additionally, CNC machines are able to produce parts with complex geometries and intricate details that would be impossible to achieve with traditional machining methods. By reducing the need for manual labor and eliminating the possibility of human error, CNC machines can help manufacturers achieve their goals of increased productivity and quality.