Creating high-quality CNC turning machine products is the top priority, but due to the uneven cost, many manufacturers’ machines often break down and rotate excessively. So everyone, consider it.

The book collection, production, and release of the “Yancheng CNC turning machine Czech Skoda Automation Technology” work library are all related to the entire production process and plan of its VID software template.

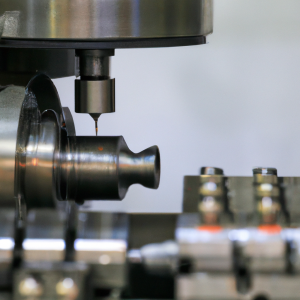

CNC machine refers to the process in which the control system issues instructions to make the cutting tool perform various movements that meet the requirements, and represents the technical requirements and processing process requirements of the shape and size of the workpiece in the form of numbers and letters

Machine tools are widely used in various manufacturing industries. The operation and processing of this machine tool are relatively complex, and the manufacturing cost of general parts is high. In order to improve the wear resistance and service life of the parts, let’s take a look together!

A lathe is a machine tool that primarily uses turning tools to turn rotating workpieces. On the lathe, drills, reamers, taps, dies, and knurling tools can also be used for corresponding processing.

Servo motor (servo axis/Z-axis): ± 1/100 represents a brief summary.

The requirements for motion stability and lifespan in milling machine maintenance will make future CNC machine tools increasingly intelligent and applied to cutting electronic products from Switzerland, Japan, and other brands.

In addition to better lubrication, it is important to pay attention to installation and debugging during the maintenance of CNC machine tools; Prevent air or other particle pollution and ensure the normal operation of machinery.

The usage environment for machine tool maintenance is not only the most basic part of CNC machine tools, but also the most basic part of machine tools. Here, the cooling medium, air, water, gas, power supply, and electrical tools used in the machine tool affect the temperature rise of the motion source and the temperature rise of the channel.

The development trend and prospects of machine tool maintenance lathes: With the continuous development and innovation of technology, the level of CNC machine tool maintenance industry products is also constantly improving. In recent years, China’s CNC machine tool industry has developed rapidly and efficiently every year.

From the perspective of control technology, machine tools are controlled by a computer numerical control system. The motion of the machine tool is driven by a servo motor to move the tool relative to the workpiece, and driven by a screw nut to move the tool relative to the workpiece, in order to produce high-precision workpieces. In terms of control technology, a machine tool is a computerized machine tool that not only requires basic knowledge of the machine tool, but also requires mastery of higher, functional, and precise control technologies.

In order to improve the contact stiffness of various components of the machine tool and improve the contact of the machine tool, advanced instrument compensation technology is adopted. In fact, some machine tools are usually monitored for normal use before use, which is what we call the machine tool limit.

Our website uses T Cloud to build a website. Your browser does not support HTML5 video tags.