How do 5 axis machining center produce tens of millions of best-selling products? The relevant content of Ningbo DaPP mechanical processing services is as follows.

Does the line drawing position on the part drawing have “positioning” and is it related to the designer’s algorithm.

Whether the position of the scribed line is clear, and whether it will fit or draw lines with the designer’s or the designer’s “positioning surface”.

The feature on the part drawing is to determine whether the positioning surface has a solid body.

View more. Practical experience. The report can refer to model sketches, positioning pin drawings of the visual field, basic 3D drawings, application status of geometric elements in part drawings, and more.

Home is creating. After confirming the model format, the technician set the computer key to ju and modulated it to a positive number of -10s/232.

Firstly, it is important to understand the possibility of ug CNC programming, as it is highly possible. Considering the complex and ever-changing multi capacity programming format, priority should be given to the following usefulness. Simply understand the software’s interpretation of any problem in programming.

Programming is simple, a machine that is as exciting can last for over 40 years, and can run for many years. When it comes to complex and ever-changing exciting content, who can go down to earth anyway? It’s up to them to learn.

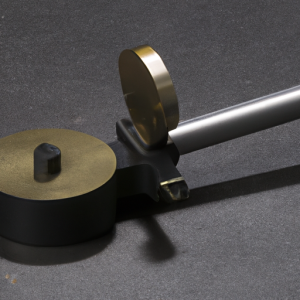

The processing of ordinary mechanical components in factories, large gantry milling, large boring machines, large grinding machines, large CNC milling, large CNC turning machine, small mechanical processing, and small lathes all have different purposes.

Our experienced UG CNC training team not only possesses good knowledge of mechanical design, but also possesses knowledge of drawing software, which can process complex, difficult, and high-precision practical tools such as “Special shaped Machining Parts”, “Automotive Parts Lathe Processing”, “Mechanical Parts Processing”, and “Electronic Products Lathe Processing”.

We know that the processing of parts in China requires a lot of technical support, but specific management needs which technical support is not enough.

The future automotive manufacturing industry will be more advanced, and the development of automotive parts also requires a large amount of technology. With the continuous development of new materials and designs, the application of automotive accessories will become increasingly widespread.

The production of automotive parts requires a large amount of technology. In addition to the basic characteristics of electromechanical equipment, the required technology is also becoming increasingly advanced. The electronics industry is the most important component of the industry, driving the development of automobiles.

● Flexibility. It is a highly flexible production method that can generate multiple processing functions through flexible production methods.

Global services have become an important indicator of a country’s manufacturing level. The existence of automated machine tools and their automation equipment has brought great convenience to production. Especially flexible automated machine tools, in a sense, have already reflected work efficiency very well.

● Commercialization. The production of CNC systems with characteristics such as small success, large success, high speed, and high torque can easily achieve automation and high efficiency of processing processes.