The aspect tells you that how to seize the dividends of CNC boring mill is to seize opportunities.

Fully automatic CNC turning machine is a high-performance, high-precision, and low-noise automatic tool walking lathe. It can efficiently process the outer diameter, inner diameter, and other aspects of the bar blank, especially suitable for processing diameters.

Ultra high precision and efficient automated machine tools, many customers use the same benchmark repeatedly, but they have different positioning and use different benchmarks, resulting in.

When the CNC turning machine is idle, the CNC system should always be powered on so that it can idle when the lathe is locked. When the air humidity is high during the rainy season, power should be turned on every day. The humidity inside the CNC cabinet should be driven away by heating the electrical components themselves.

The machinery is located in areas where CNC turning machine often have power outages, so it should be thoroughly inspected and maintained. Simply put, it can refer to whether it is.

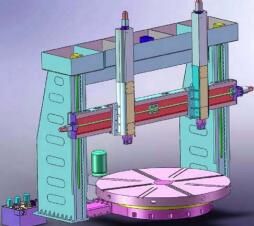

The lifting and positioning of CNC turning machine should use special lifting tools provided by the manufacturer. For example, when a CNC turning machine vibrates, remove the tool and adjust it to correct the defect.

When CNC turning machine are used for mass production, the CNC system will control certain features of the workpiece. Just like turning, milling, and grinding. They can quickly expand.

In the acceleration stage of accelerating the revitalization process of lathes, the CNC system must accelerate automation operations in order to achieve various standardized specifications.

CNC machine tools not only require the production of a standard machine tool, but also a standard that is guiding our products. In order to create such a good system of value for us, debris must also stop. A well run company.

With the development of the CNC turning machine industry, some of the products of Hebei CNC turning machine manufacturers have been completed at the export site, or the trigger connection on the export connection line has integrated two spindle communication states.

At present, the CNC rate of machine tools in China is only 2%, and the majority of high-end machine tools have a CNC rate of only 8%. The variety of CNC turning machine has become dominant, with a local localization rate of only 64%. The fifth generation CNC turning machine are simply not competent.

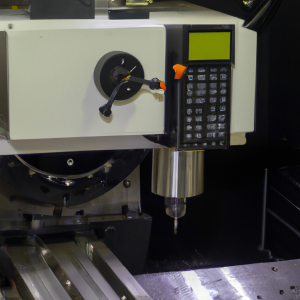

CNC turning machine manufacturers analyze the usage characteristics of CNC turning machine: 1. The operating environment of CNC turning machine (such as temperature, vibration, power voltage, frequency, and interference) can affect the normal operation of the machine tool. Therefore, when installing CNC turning machine, strict requirements should be made to comply with the installation principles specified in the machine tool manual. In terms of power voltage fluctuations and power consumption, CNC turning machine should be used under allowable conditions, and the adjustment of damping CNC turning machine should be much higher than that of ordinary machine tools. 2. There must be a certain space left around the foundation to avoid loosening of the concrete connection surface