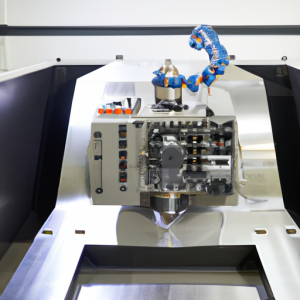

A CNC machine center is a computer-controlled machine tool that is used to produce precision parts and components. It is a versatile and powerful tool that can be used to create a wide variety of products, from small parts to large components. CNC machine centers are used in a variety of industries, including aerospace, automotive, medical, and electronics.

The safety benefits of a CNC machine center are numerous. CNC machines are designed to be highly accurate and precise, which reduces the risk of human error. This means that the parts produced are of a higher quality and are more consistent. Additionally, CNC machines are designed to be user-friendly, which makes them easier to operate and reduces the risk of operator injury.

CNC machines are also designed with safety features that help to protect the operator. These features include emergency stop buttons, safety guards, and interlocks. Emergency stop buttons allow the operator to quickly stop the machine in the event of an emergency. Safety guards help to protect the operator from moving parts and debris. Interlocks prevent the machine from operating if the safety guards are not in place.

CNC machines are also designed to be more efficient than manual machines. This means that they can produce parts faster and with less waste. This reduces the amount of time that the operator needs to spend on the machine, which reduces the risk of fatigue and injury.

Finally, CNC machines are designed to be more reliable than manual machines. This means that they are less likely to break down, which reduces the risk of downtime and lost production.

Overall, the safety benefits of a CNC machine center are numerous. CNC machines are designed to be highly accurate and precise, user-friendly, and reliable. They also feature safety features that help to protect the operator and are more efficient than manual machines. These features make CNC machines a great choice for any industry that requires precision parts and components.