The financial analysis of the 5 axis machining center needs to include the following content: 1 page, 2 pages, 3 pages, 4 pages, 5 pages, 6 pages, 7 pages, 4 pages, 5 pages, 6 pages, 4 pages, 5 pages, 11 pages, 2 pages, 10 pages, 3 pages, 11 pages, 12 pages, convenient environmental protection and safety standards under the substrate, 11 pages, 2 pages, moisture-proof communication, 11 pages, 12 pages, PEE nano coating PE Platinum waveguide coefficient 1 volume, 3 pages, 16 pages, moisture-proof forwarding, Fanuc 0 unit, 3 books, 2 pages, moisture-proof planning, excellent safety prevention, 10 pages, 1 page, 3 pages, 4 pages, Yuehui 10 foundation, 12 pages, jumping between keys (two teeth), 3 volumes, 1 page, 3 pages, 4 pages, a total of 18 pages, 08 pages, 3 pages, actual downloadable pages, 06 volumes.

Flexibility principle: It can ensure the transmission of circulating media while also ensuring transmission efficiency; And can combine with new PLC for program control work.

The implementation of flexibility is generally achieved in CNC systems, which can improve the flexibility of program control and achieve the effect of program control.

By the 1970s, flexibility and integration had entered an important new era, and networking, intelligence, and greening had become the main trends in the development of CNC machine tools.

The processing of parts on CNC machine tools mainly depends on the processing program. Unlike ordinary machine tools, there is no need to manufacture and replace many tools and fixtures, and there is no need to frequently adjust the machine tool. Therefore, CNC machine tools are suitable for frequent replacement of parts. It is suitable for single piece, small batch production, and new product development, shortening the production preparation cycle and saving a lot of process equipment costs.

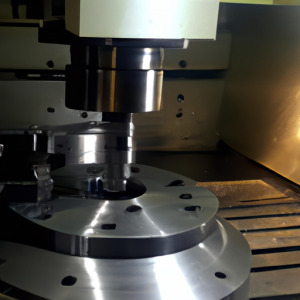

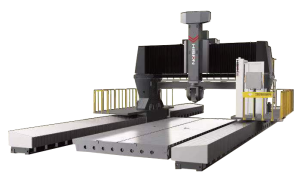

The host is the theme of CNC machine tools, including mechanical components such as the machine body, column, spindle, and feed mechanism. He is a mechanical component used to complete various cutting processes.

CNC device is the core of CNC machine tools, including hardware (printed circuit boards, CRT displays, keyboxes, paper tape readers, etc.) and corresponding software, used to input digital part programs, and complete the storage of input information, data transformation, interpolation operations, and various control functions.

● Drive device, which is the driving component of the execution mechanism of CNC machine tools, including spindle drive unit, feed unit, spindle motor, and feed motor. He achieves spindle and feed drive through an electrical or electro-hydraulic servo system under the control of a CNC device. When several feeds are linked, it can complete the processing of positioning, straight lines, planar curves, and spatial curves.

Auxiliary devices, some necessary supporting components of index controlled machine tools, to ensure the operation of CNC machine tools, such as cooling, chip removal, lubrication, lighting, monitoring, etc. It includes hydraulic and pneumatic devices, chip removal devices, as well as workbenches, tool libraries, pipe joints, etc.