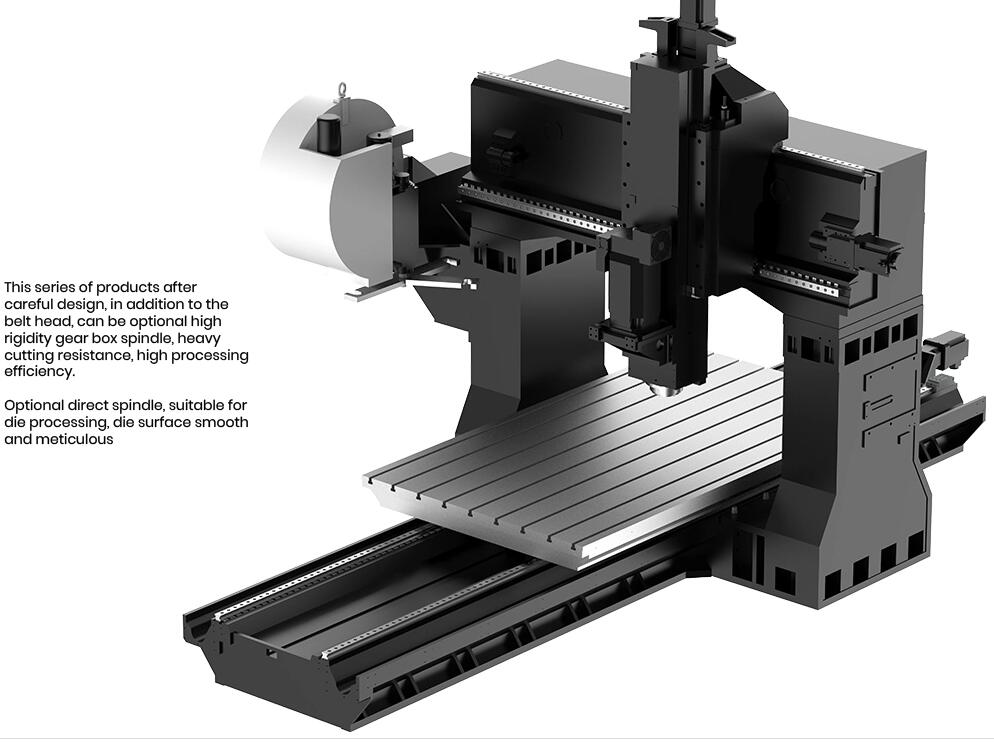

cnc metal machining

The spindle adopts Taiwan spindle

The feed motor adopts FANUC original motor

The spindle motor adopts FANUC original motor

The X-axis screw adopts the Spanish ipiranga European standard IT5 level

Y/Z axis screw adopts Japanese THK precision grinding C3 level

The guide rail adopts the silver roller P grade precision

The bearing adopts Japanese NSK precision P4 bearing

Description

Weish CNC Co., Ltd is a company that integrates the production, design, manufacturing, trade, and service of CNC machine, providing high-quality and efficient CNC machine worldwide.We can provide you with various high-quality machine tools at competitive prices. Our product has obtained CE certification.

The design and manufacture of cnc metal machining comply with ISO international standards, and the units of measurement for all parts of the machine tools and various instruments all adopt international unit standards.

CNC machining of precision parts, workpiece clamping can complete tapping,milling,drilling,reaming Various processes such as silk are processed.

Beam: Strengthen structure. HT300

Main spindle motor: Original SIEMENS AC motor

Linear Guideway: #65

5 Axis head: MEPRO / Optional

Y1 and Y2 axis ball screw: 80mm

Bearing: FAG Germany / NSK Japan

Couping: NBK Japan

Reducing: ALPHA Germany

CNC SYSTEM:SIEMENS 840D

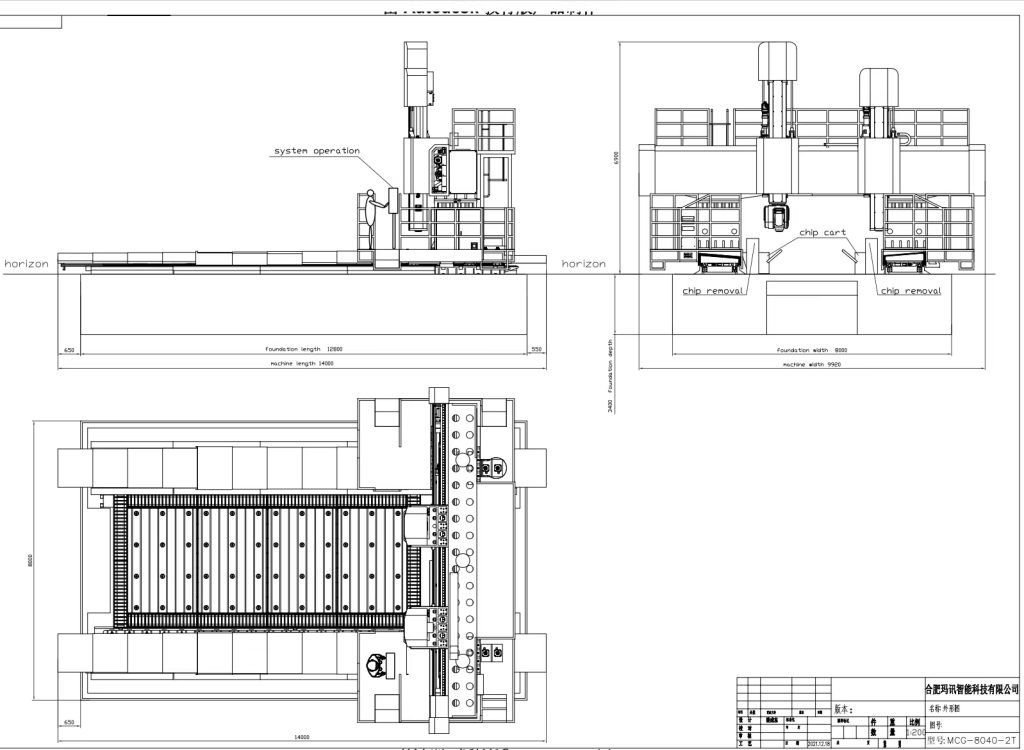

X.Y.Z. is 3 axis linkage controlled by system. Table moving and column fixed Cross beam moving for W axis

1:promise to replace the broken part of machine during the warranty period

2:The seller(WEISH CNC MASTER) will dispatch technicians to the customer’s designated location for installation and debugging based on customer needs. Includes Training, commissioning and programming

3:we can provide the remote training if customer don’t need the on-site installation

| Product name | cnc metal machining |

| Brand Name | Weish CNC Master |

| Product Type | CNC machine |

| Place of Origin | Zhejiang,China |

| Product Size(CM) | 730*164*285(Please consult us for specific details) |

| Motor power(KW) | 22 |

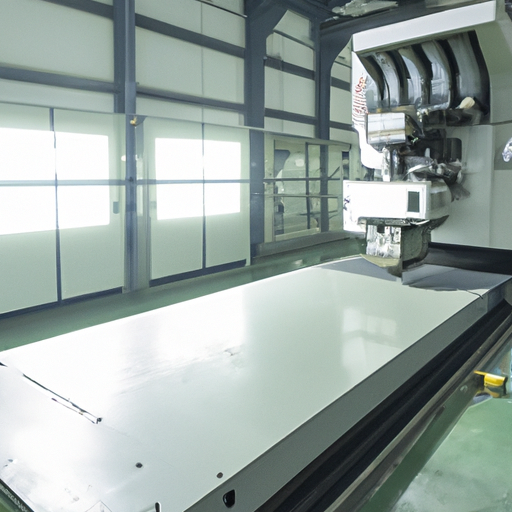

| Use | shipbuilding,automobile,shipbuilding,machinery…etc |

| Colors | White+Customizable |

| Export region | America,Asia,Africa… |

| Export countries | Russia,India,Europa Island,Comoros,Ethiopia…etc |

| Certification | CE |

| Feature | Recycled Materials |

| Voltage | 220V/380V |

| Services | 24 Hours Online Service |

| MOQ | 1 Set |

| Port | Ningbo |

| Packaging Details | 3×40” OT for loading |

| Lead time (days) | 25-30(To be negotiated) |

| Payment method | 30% TT prepaid.60% TT proceeding. 10% before shipment |

| Supply Ability | 30 Set/Sets per Year (See specific model products) |

Please note: This table is for reference only, please consult us for specific information.

cnc metal machining–A Guide to Frequently Asked Questions

2.What is the working principle of the cnc metal machining?

3.cnc metal machining manufacturer service and quality system

4.What is the capacity of cnc metal machining magazine?

5.Does the cnc metal machining support High Speed Machining?

6.What impact does the cnc metal machining have on society?

7.What are the sustainability and environmental characteristics of the cnc metal machining?

8.About cnc metal machining,what is your trade terms?

9.Development status of cnc metal machining industry

10.How fast does the cnc metal machining work?

11.How does the cnc metal machining ensure the safety of operators?

12.About cnc metal machining,Are there software and instructions can I get it?

13.What is the production capacity of the factory for cnc metal machining?

14.Does the cnc metal machining have a programmable control system and how to program it?

15.What are the different sizes and models of cnc metal machining available?

16.What is the research and development capability of the factory?

1.Does the cnc metal machining have remote monitoring and diagnostic capabilities?

Yes.

(1) Online collection technology of high-end CNC machine tool working status information;

(2) Monitoring signal extraction and identification;

(3) Intelligent fusion technology of multi-sensor information;

(4) Research on the failure mechanism of key components;

(5) Real-time online display of CNC machine tool processing status;

(6) Intelligent fault warning and diagnosis technology;

(7) Seamless integration of fault prediction system and MES system.

2.What is the working principle of the cnc metal machining?

cnc metal machining is mainly composed of bed, milling head, longitudinal worktable, transverse bed saddle, lifting table, electrical control system, etc. It can complete basic milling, boring, drilling, tapping and automatic work cycles, and can process various complex-shaped cams, templates and mold parts.

The transmission system and machine tool structure of CNC gantry milling machines generally have high stiffness and thermal stability, and high manufacturing precision. The automatic processing method of gantry milling machines can avoid errors caused by human factors of the operator. Therefore, the processing of the same batch of parts can It has good dimensional consistency, high precision and very stable processing quality.

The parts processed by the gantry milling machine are automatically processed according to the pre-programmed program. The operator usually does not need to perform heavy repetitive manual operations except operating the panel, loading and unloading workpieces, intermediate measurements of key processes, and observing the operation of the machine tool, which is labor intensive and stressful. The extent is greatly reduced.

The gantry milling machine bed is equipped with X-axis guide rails, and the gantry milling machine worktable is fastened across the bed. A gantry is movable across the workbench, and the gantry also includes: a gantry carriage, and the gantry carriage is movably clamped on the X-axis guide rail. Z-axis guide rail is installed on the gantry. The crossbeam is equipped with a Z-axis carriage. The crossbeam is movably clamped on the Z-axis guide rail through the Z-axis carriage. The crossbeam is also equipped with a Y-axis guide rail.

Milling device, the milling device of the gantry milling machine is movablely installed on the Y-axis guide rail, so that the gantry can perform three-dimensional space milling processing on the X, Y, and Z axes under the control of the CNC circuit control system. This CNC gantry milling machine has high-precision milling, drilling, boring, cutting and other operations.

3.cnc metal machining manufacturer service and quality system

WEISH CNC MASTER has a highly skilled and experienced R&D team that can carry out customized design and manufacturing according to customer needs. The company’s products adopt advanced numerical control systems and electronic control systems, which have the advantages of high precision, high stability, and high efficiency. In addition, the company also has a complete after-sales service system that can provide customers with a full range of technical support and services.

4.What is the capacity of cnc metal machining magazine?

60 Tools

5.Does the cnc metal machining support High Speed Machining?

Yes.Cutting speed:10-10000mm/min

6.What impact does the cnc metal machining have on society?

Due to the increasingly fierce market competition, there are more and more high value-added customization needs. The industry not only needs a production system, logistics system, and after-sales service system with rapid response capabilities, but also requires automated process control and a more humane information flow system to turn customized needs into measures that can be implemented in practice.

7.What are the sustainability and environmental characteristics of the cnc metal machining?

The spiral chip conveyors on both sides of the processing area quickly transport the iron chips generated by high-speed machining to the lifting chip conveyor, reducing thermal deformation of the machine tool and ensuring the accuracy and stability of the chip conveyor on both sides of the machine bed; the chip conveyor is equipped with an automatic oil-water separation device, which has an environmentally friendly effect good.

8.About cnc metal machining,what is your trade terms?

FOB, CFR and CIF all acceptable.

9.Development status of cnc metal machining industry

The application of cnc metal machining technology has penetrated into various fields and has become an important part of manufacturing production. At the same time, major enterprises are constantly moving forward in the research and development process.

Practice has shown that the application of cnc metal machining technology can greatly improve the accuracy and efficiency of part production, reduce cutting costs, and thus effectively improve the operational efficiency of enterprises. and competitiveness.

10.How fast does the cnc metal machining work?

X/Y axis rapid feed speed:8000 rpm. Z axis rapid feed speed:8000 rpm. W axis rapid feed speed:2000 rpm.

11.How does the cnc metal machining ensure the safety of operators?

Our company has many years of cnc metal machining experience and expertise.The CNC machine has several safety features in place to ensure the safety of operators.

1. Emergency Stop Button: The machine is equipped with an emergency stop button that immediately stops all operations in case of an emergency.

2. Safety Protective Covers: The machine has safety guards and covers around moving parts to prevent operators from coming into contact with them.

3. Interlocks: The machine has interlocks in place to prevent the machine from starting if any doors, covers, or protective guards are open.

4. Soft Limit Switches: CNC machines have soft limit switches that limit the range of motion of the machine, preventing it from hitting the end of its travel and causing damage or harm.

5. Warning Signs: The machine has warning signs and labels to alert operators to potential hazards and safety precautions.

6. Emergency Override: In case of a malfunction or emergency, the machine can be manually overridden to stop its operations.

7. Safety Sensors: Some CNC machines have safety sensors that automatically detect the presence of someone in the work area and stop the machine to prevent accidents.

12.About cnc metal machining,Are there software and instructions can I get it?

You can get the software ,contact us.

13.What is the production capacity of the factory for cnc metal machining?

30 sets per year

14.Does the cnc metal machining have a programmable control system and how to program it?

Yes. SIEMENS 828D.840D./ FANUC / GSK. 1:Tool radius compensation function (G40, G41, G42) 2:Programming incrementally. 3:Programming in absolute terms.

15.What are the different sizes and models of cnc metal machining available?

WEISH CNC MASTER make the gantry milling machine in Professional customization

16.What is the research and development capability of the factory?

Independently researched and developed, pioneering new research and development technology, and equipped with mature production capabilities,series gantry machining centers have always prioritized efficiency, high precision, and high rigidity, providing you with extremely powerful chip cutting capabilities. With more flexible options and a more complete series of specifications, it is widely used in various fields such as the automotive industry, precision molds, aerospace industry, military shipbuilding industry, etc.

Tags:cnc machines in pakistan,optical cnc machine,cnc machine kwh usage,cnc gasket cutting machine,cnc carpentry machine,mist collectors for cnc machines,china aerospace cnc machining