cnc machine manufacturers

We make this type customerized up to our clients

Description

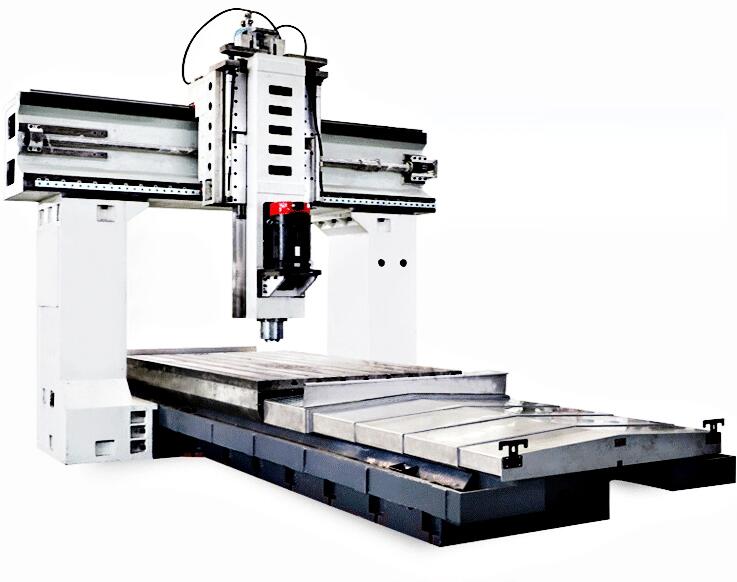

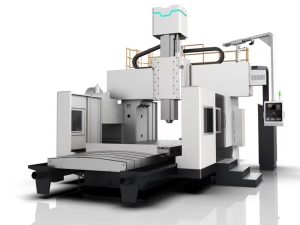

CNC machine manufacturers specializing in the production of various types of CNC machine tools. These manufacturers produce a range of machines suitable for various applications, including milling, turning, grinding, laser cutting, etc

| Item | Name | Brand | Remark | ||||

| 1 | ATC | OKADA TAIWAN | Optional | ||||

| 2 | Feeding motor | FANUC | X axis 36NM two double drives, YZ axis torque 36NM, Z axis with brake | ||||

| 3 | Main motor | FANUC | 22/26KW | ||||

| 4 | System | FANUC OIMF | |||||

| 5 | X-Screw | Ipiranga Spain | IT5 | ||||

| Y/Z Screw | THK | C3, | |||||

| 6 | Bearing | NSK | P4 | ||||

| 7 | Electric part | ||||||

| 8 | Leaner guideway | HIWIN Taiwan | 55 rollers | ||||

| 9 | encoder | Absolute encoder | No need to return to the origin | ||||

| 10 | Guideway | HIWIN Taiwan | 55 roller | ||||

| 11 | Main spindle | MicroLab Taiwan | |||||

| Item | |||||||

| 1 | X travel | mm | 12000 | ||||

| 2 | Y travel | mm | 4400 | ||||

| 3 | Z travel | mm | 1200 | ||||

| 4 | Between column | mm | 4200 | ||||

| 5 | Distance from spindle end to worktable | mm | 600-1800 | ||||

| 6 | Worktable size | mm | 8000*3000 | ||||

| 7 | Max loading | T | 8/M2 | ||||

| 8 | T slot | No. | 28 | ||||

| 9 | T-slot size/spacing | mm | 28/250 | ||||

| 10 | Spindle drive mode | Direct drive | |||||

| 11 | Spindle speed | rpm | 10-6000 | ||||

| 12 | Motor power | kW | 22/26 | ||||

| 13 | Spindle torque | N.m | 170+BFGear box 680NM | ||||

| 14 | Spindle taper | ISO7:24NO50 | |||||

| 15 | Pull nail specifications | P50T-2-MAS503 | |||||

| 16 | Spindle dia | mm | Φ190 | ||||

| 17 | X、Y、Z Rapid move | m/min | 7/7/7 | ||||

| 18 | X、Y、Z servo motor | kW | 5.2*2/5.2/5.2 | ||||

| 19 | X、Y、Z servo torque | N.m | X-36*4,YZ-36*3/36*3 | ||||

| 20 | X、Y、Z servo motor | rpm | 3000 | ||||

| 21 | X/Y/Z Dia of Screw | mm | Φ10020/8020/Φ6320 | ||||

| 22 | Feeding speed | mm/min | 6000 | ||||

Tag: cnc machine manufacturers

How can CNC machine manufacturers maintain competitiveness in the CNC machine tool industry?

CNC machine manufacturers can maintain the competitiveness of the CNC machine tool industry by adopting various strategies and practices.

Innovation: Continuous innovation in machine design, control systems, and tool technology enables manufacturers to maintain a leading position in the industry. This includes developing machines with advanced functionality, higher accuracy, and improved energy efficiency.

Advanced Materials: Use cutting-edge materials such as high-strength alloys and composite materials in machine structures to improve durability and performance.

Customization: Provide customized solutions and customization options to meet the specific needs of different industries and applications.

Digital integration: Implement Industry 4.0 practices by integrating digital technologies such as the Internet of Things, artificial intelligence, and data analysis to improve machine monitoring, maintenance, and overall efficiency.

Energy efficiency: Developing energy-saving machines to reduce operating costs and meet sustainable development goals.

Global expansion: Expanding into international markets and establishing global business to leverage new opportunities and expand customer base.

After sales support: Provide excellent customer support, maintenance, and training services to ensure customer satisfaction and machine lifespan.

R&D: Invest in R&D, create cutting-edge solutions, and maintain competitiveness in rapidly developing industries.

Quality control: Implement strict quality control and testing procedures to ensure the reliability and accuracy of the machine.

Cost efficiency: Efficient manufacturing processes, cost management, and supply chain optimization, providing competitive pricing.

Environmental responsibility: demonstrate commitment to environmental responsibility by complying with environmental regulations and reducing the impact of machines on the environment.

Diversification: Expand product portfolio, including various machine types such as milling, turning, grinding, and additive manufacturing.

Customer feedback: Actively seek feedback from customers to understand their constantly changing needs and challenges, and use this information for product development.

Brand building: Establishing a strong brand identity and reputation in the industry can help attract new customers and retain existing ones.

You must be logged in to post a review.

Reviews

There are no reviews yet.