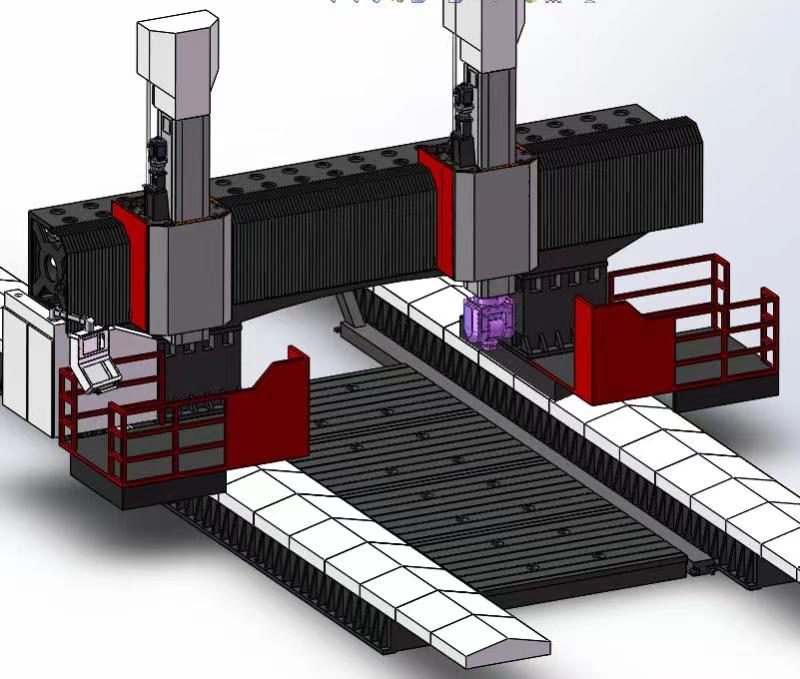

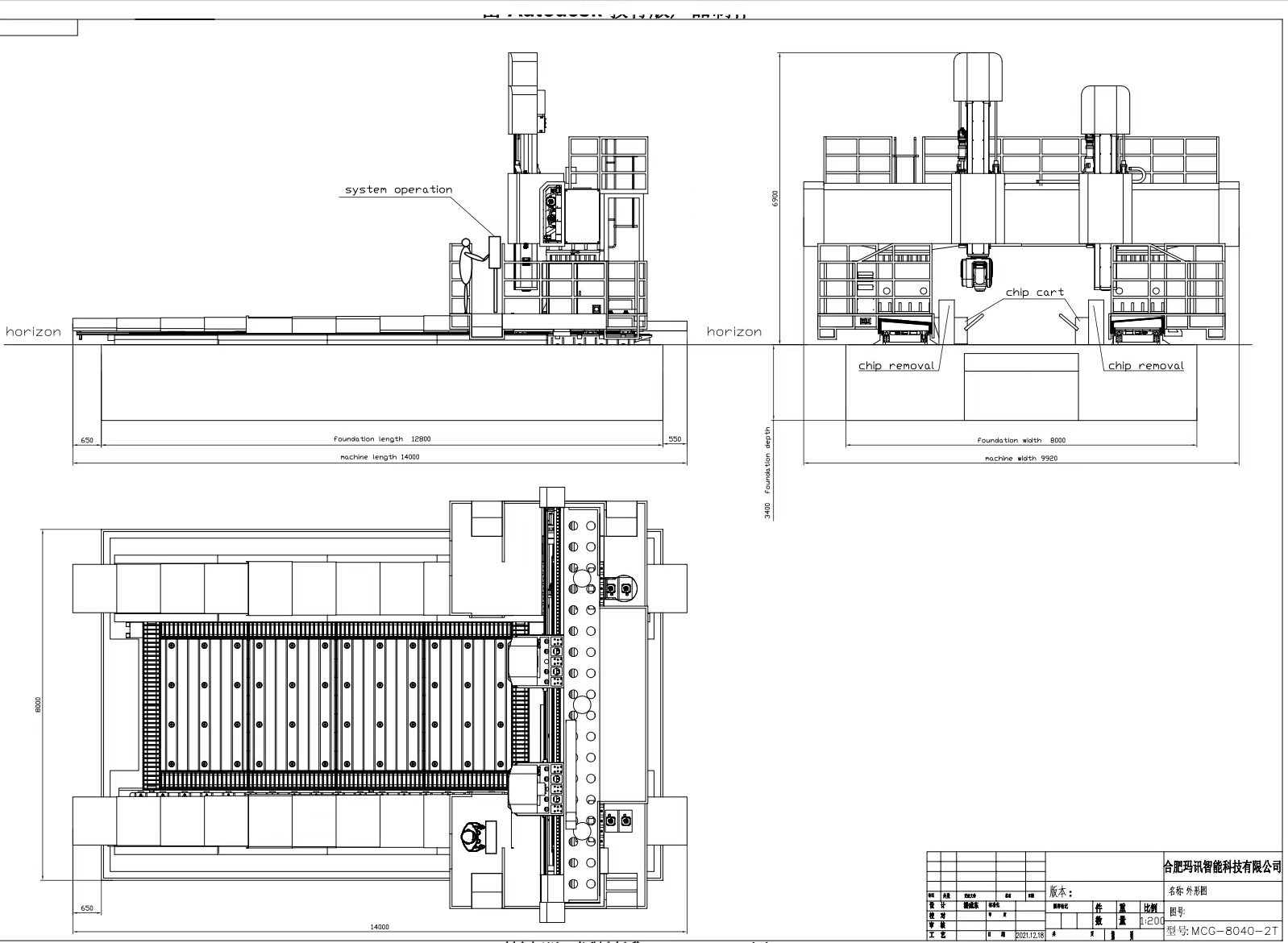

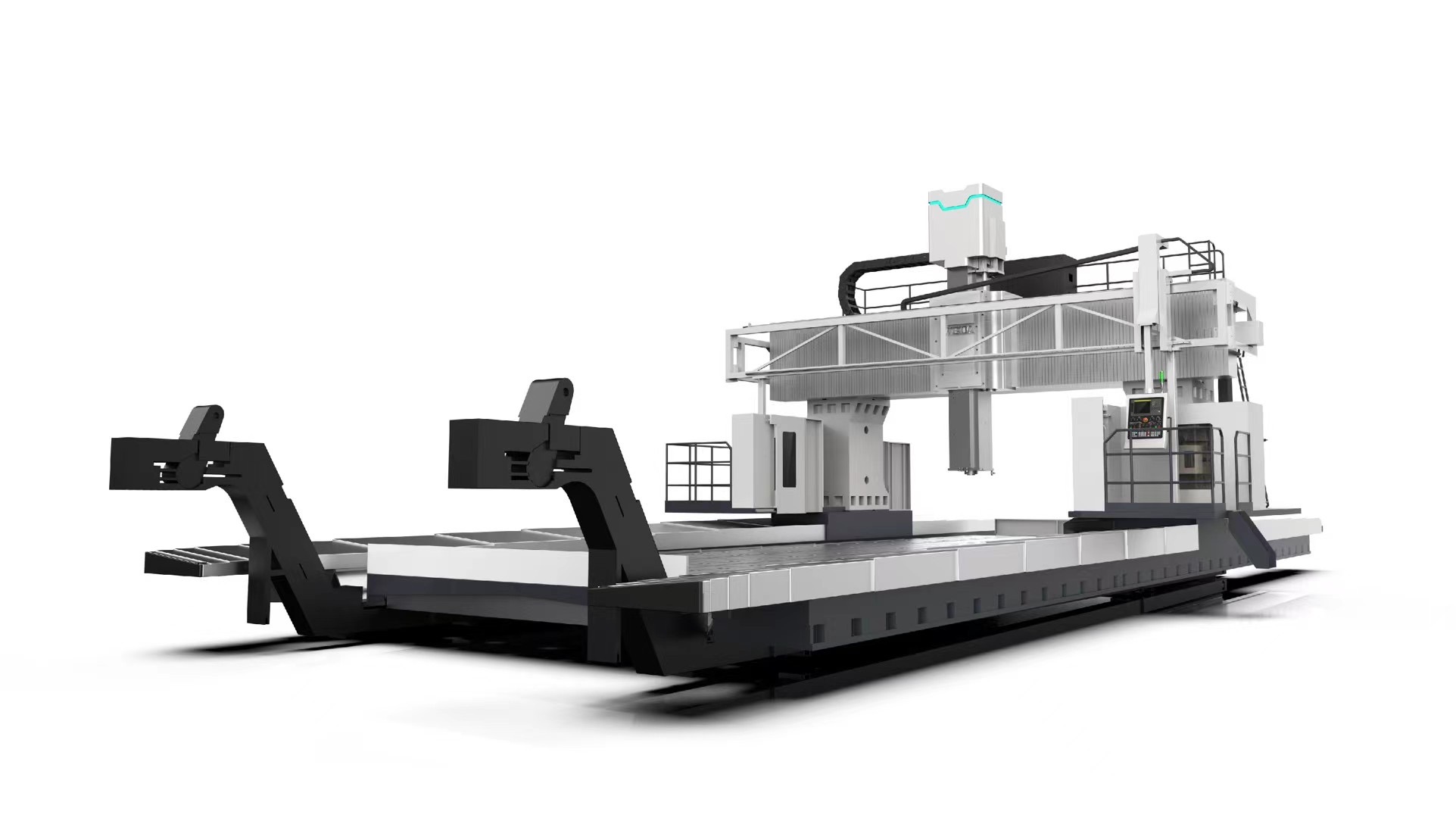

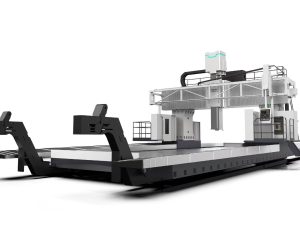

5 axis large gantry machining center

We make this type customerized up to our clients

Description

| No | Item | |

| 1 | Table size | 15000 mm×3000 mm |

| 2 | All axis move | X:15000 mm

Y1: 5800 mm Y2: 5800 mm Z1: 1550 mm Z2: 1550 mm |

|

3 |

Table loading | 7000kg/M2

Slot:36×250mm |

| 4 | Axis control | 5 axis linkage working |

| 5 | Distance between spindle end surface and worktable surface | 600~2150 mm |

| 6 | Ram size | 500×500 mm |

| 7 | Between column | 4100 mm |

| 8 | Main spindle | Main spindle:Siemens AC Servo Motor

Motor poser:22/26Kw Max torque:1120Nm Taper:ISO50 BT50 Spindle speed:10~6000RPM Spindle dia:Φ190 mm Spindle taper hole cleaning method:Air Spindle head balance method: nitrogen balance Spindle positioning method: encoder Bearing cooling method: constant temperature oil cooling Bearing lubrication medium: imported FAG grease Bearing lubrication method: Grease |

| 9 | 5 axis head | A-axis rated torque: 1060Nm

A-axis hydraulic clamping torque: 4000Nm (60bar) Maximum swing speed of A-axis: 60rpm A-axis rotation angle range: ±110° A-axis encoder type: absolute C-axis rated torque: 1350Nm C-axis hydraulic clamping torque: 4000Nm (60bar) Maximum swing angular speed of C axis: 60rpm C-axis rotation angle range: ±360° C-axis encoder type: absolute Indexing:0.001° Spindle The highest torque of the spindle: 298Nm Maximum spindle speed: 10000rpm ( Adjustable) Spindle rated current: 173.5A Taper:HSK-A100 Lubrication method: grease lubrication |

| 10 | Driven system | Three-axis feed motor: Siemens AC servo motor

X-direction rack and pinion transmission: dual-axis output, dual-motor anti-backlash, four motors Y1-direction screw diameter: φ80mm Y2-direction screw diameter: φ80mm Z1-direction screw diameter: φ63mm Z2-direction screw diameter: φ63mm |

| 11 | Motor power torque | X: 36N.M (four reducers, reduction ratio 1:50)

Y1: 36N.M (precision reducer, reduction ratio 1:4) Y2: 36N.M (precision reducer, reduction ratio 1:4) Z1: 36N.M (brake, precision reducer, reduction ratio 1:3) Z2: 36N.M (brake, precision reducer, reduction ratio 1:3) |

| 12

13

|

Rapid move | X axis: 12 m/min

Y1 axis: 12 m/min Y1 axis: 12 m/min Z1 axis: 10 m/min Z2 axis: 10 m/min |

| 12

13

|

Feed rate

Machine accuracy |

X、Y、Z:1~6000 mm/min |

| positioning accuracy: | ||

| X:0.020mm | ||

| Y1:0.015mm Y2:0.015mm | ||

| Z1:0.015mm Z2:0.015mm | ||

| Re positioning accuracy: | ||

| X:0.015mm | ||

| Y1:0.010mm Y2:0.010mm | ||

| 14 | Z1:0.010mm Z2:0.010mm | |

| 15 | Three-axis Linear | X: P grade roller 65mm (four linear rails)

Y: P grade roller 65mm (two linear rails) Z: Four-sided hard rail |

| 16 | Electrical cabinet | The electrical control box is sealed and equipped with an electrical cabinet empty |

| 17 | Lubricant distribution method | Quantitative allocation |

| 18 | Lubricating oil flow | 150ml/min |

| 19 | Maximum pressure of coolant | 0.6MPa |

| 20 | Maximum coolant flow | 50 L/min |

| 21 | 0.6MPa | |

| 22 | Available air pressure range | 0.45~0.6MPa |

| 23 | Air flow | 0.6~0.9 m3/min |

| 24 | Total power | 180KVA |

| 25 | Over size | 15500×10000×8000 |

| 26 |

You must be logged in to post a review.

Reviews

There are no reviews yet.