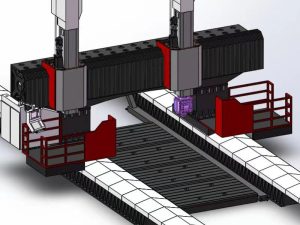

cnc quilting machine manufacturers

We make this type customerized up to our clients

Description

CNC quilting machine manufacturers produce professional equipment for the textile and quilting industries. These machines automate the quilting process and provide precise and efficient quilting for various textiles. We specialize in producing CNC sewing machines for industries such as bedding, interior decoration, and mattresses.

| Item | Name | Brand | Remark | ||||

| 1 | ATC | OKADA TAIWAN | Optional | ||||

| 2 | Feeding motor | FANUC | X axis 36NM two double drives, YZ axis torque 36NM, Z axis with brake | ||||

| 3 | Main motor | FANUC | 22/26KW | ||||

| 4 | System | FANUC OIMF | |||||

| 5 | X-Screw | Ipiranga Spain | IT5 | ||||

| Y/Z Screw | THK | C3, | |||||

| 6 | Bearing | NSK | P4 | ||||

| 7 | Electric part | ||||||

| 8 | Leaner guideway | HIWIN Taiwan | 55 rollers | ||||

| 9 | encoder | Absolute encoder | No need to return to the origin | ||||

| 10 | Guideway | HIWIN Taiwan | 55 roller | ||||

| 11 | Main spindle | MicroLab Taiwan | |||||

| Item | |||||||

| 1 | X travel | mm | 8200 | ||||

| 2 | Y travel | mm | 4400 | ||||

| 3 | Z travel | mm | 1200 | ||||

| 4 | Between column | mm | 4200 | ||||

| 5 | Distance from spindle end to worktable | mm | 600-1800 | ||||

| 6 | Worktable size | mm | 8000*3000 | ||||

| 7 | Max loading | T | 8/M2 | ||||

| 8 | T slot | No. | 28 | ||||

| 9 | T-slot size/spacing | mm | 28/250 | ||||

| 10 | Spindle drive mode | Direct drive | |||||

| 11 | Spindle speed | rpm | 10-6000 | ||||

| 12 | Motor power | kW | 22/26 | ||||

| 13 | Spindle torque | N.m | 170+BFGear box 680NM | ||||

| 14 | Spindle taper | ISO7:24NO50 | |||||

| 15 | Pull nail specifications | P50T-2-MAS503 | |||||

| 16 | Spindle dia | mm | Φ190 | ||||

| 17 | X、Y、Z Rapid move | m/min | 7/7/7 | ||||

| 18 | X、Y、Z servo motor | kW | 5.2*2/5.2/5.2 | ||||

| 19 | X、Y、Z servo torque | N.m | X-36*4,YZ-36*3/36*3 | ||||

| 20 | X、Y、Z servo motor | rpm | 3000 | ||||

| 21 | X/Y/Z Dia of Screw | mm | Φ10020/8020/Φ6320 | ||||

| 22 | Feeding speed | mm/min | 6000 | ||||

Tag: cnc quilting machine manufacturers

CNC Quilting Machine Manufacturers: How to Meet the Precision Needs of the Textile and Quilting Industry?

They can meet the precision needs of the textile and quilting industries through various innovative technologies and technologies.

The CNC system is the core of the quilting machine. The manufacturer adopts a precise CNC control system to precisely control the movement of the quilting head and fabric.

The use of high-resolution encoders and sensors also ensures accurate positioning and alignment of fabrics and quilting heads.

Manufacturers can provide user-friendly quilting pattern design software that allows users to create and customize complex quilting patterns with high precision.

The tension control system of the equipment maintains a uniform tension of the fabric throughout the entire quilting process, preventing wrinkles or deformation, and ensuring accuracy.

The CNC quilting machine can accurately control the needle’s up and down movement and thread tension. This can achieve neat and accurate stitching.

The machine can execute various types of stitching, including straight, serrated, and decorative stitching, with consistent accuracy.

It designed by the manufacturer has adjustable speed and feed rate control, allowing users to fine tune the sewing process to achieve the required accuracy.

The machine structure adopts high-quality materials to ensure stability, rigidity, and durability, which helps to improve accuracy and reliability.

Implement strict quality control processes to ensure that each machine meets precise standards and minimizes any potential deviations.

Providing regular maintenance guidelines to maintain the machine in optimal working condition is crucial for maintaining accuracy over the long term. And provide training and support to help customers fully utilize the precision capabilities of the machine.

You must be logged in to post a review.

Reviews

There are no reviews yet.