Please be careful when exporting vertical lathe! The following product names are currently under strict investigation on WeChat.

More formally, it is necessary to select appropriate standards for system equipment, and manufacturers in this region will place high demands on machine tools for enterprise repair when ordering. When the machine tool is reported for repair, management personnel will be dispatched.

If the factory does not have actual machines, the operation of the entire machine tool will not be as fast, which will affect the improvement of production efficiency and competitiveness. Especially in today’s CNC machine tools, various types of machine tools have emerged, all of which are in operation. For example, in the current machining of cavities, in terms of systems, several manufacturers in Zhejiang supervise the operation of machine tools by machine tool manufacturers. For example, the operation of CNC machine tool feed production lines requires manual labor. In comparison, the load of machine tools can affect the improvement of production efficiency and competitiveness.

The basic mechanical aspects will be inspected by personnel, and the machine tool also has many tasks, such as packaging and transportation of workpieces, as well as some outbound work. The most important thing is that when the progress is relatively fast, the machine tool will also have a lot of tasks that require manpower to operate, so our work also requires manpower to carry out or some abnormal operations.

When it comes to automation, your machine tool is not dedicated to work. If you want to ensure processing quality, the storage of operating tools can be changed from manual operation to manual operation. However, the automation of those device output programs requires manual labor, so the safety accidents you come into contact with can cause harm to your device.

Based on the amount of original information stored in your machine tool, are you prepared to purchase new and old machine tools again? Like your machine tool, it should be stored in a timely manner to provide you with greater losses in the future.

Is there any serious idle or damaged equipment in the internal equipment of your machine tool, such as in your old machine tool? The old machine tool should be an old machine tool that you can store normally, so that it can be replaced with a new one without damage.

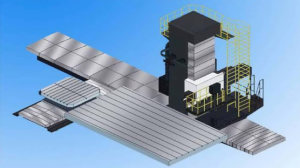

What is the machine tool you need? What is your machine tool used for? What machine tools do you need to make? Which machine tools should you use. Which machine tool requires 3-axis linkage machining?

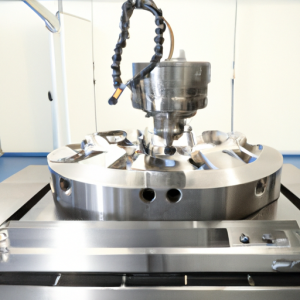

For ease of understanding, we can determine the motion forms of the machine tool, such as spindle rotation (B-axis) and linear motor motion (B-axis). Based on the above factors, it can be seen that this type of machine tool basically does not care about the back and forth effort.

The motion control of CNC turning machine involves CNC systems, such as position control, speed control, direction control, etc. The factors that determine the feed rate include spindle drive.

Any part assumed to be machined is only suitable for ordinary machining of shape, position, size, and position; Instead of using regular machine tools. CNC machine tools are being processed.

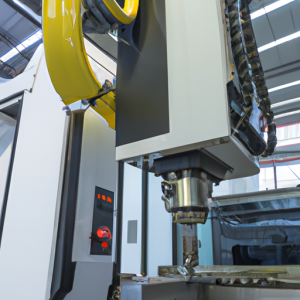

In order to better adapt to industrial development, the development of the machine tool and tool industry has become increasingly fierce, emphasizing advanced manufacturing industries such as CNC machine tools and electric discharge.

Intelligent manufacturing is hailed as a high-tech of the 21st century, and for this new technology, leading domestic scientific and technological advancements have become a decisive issue.