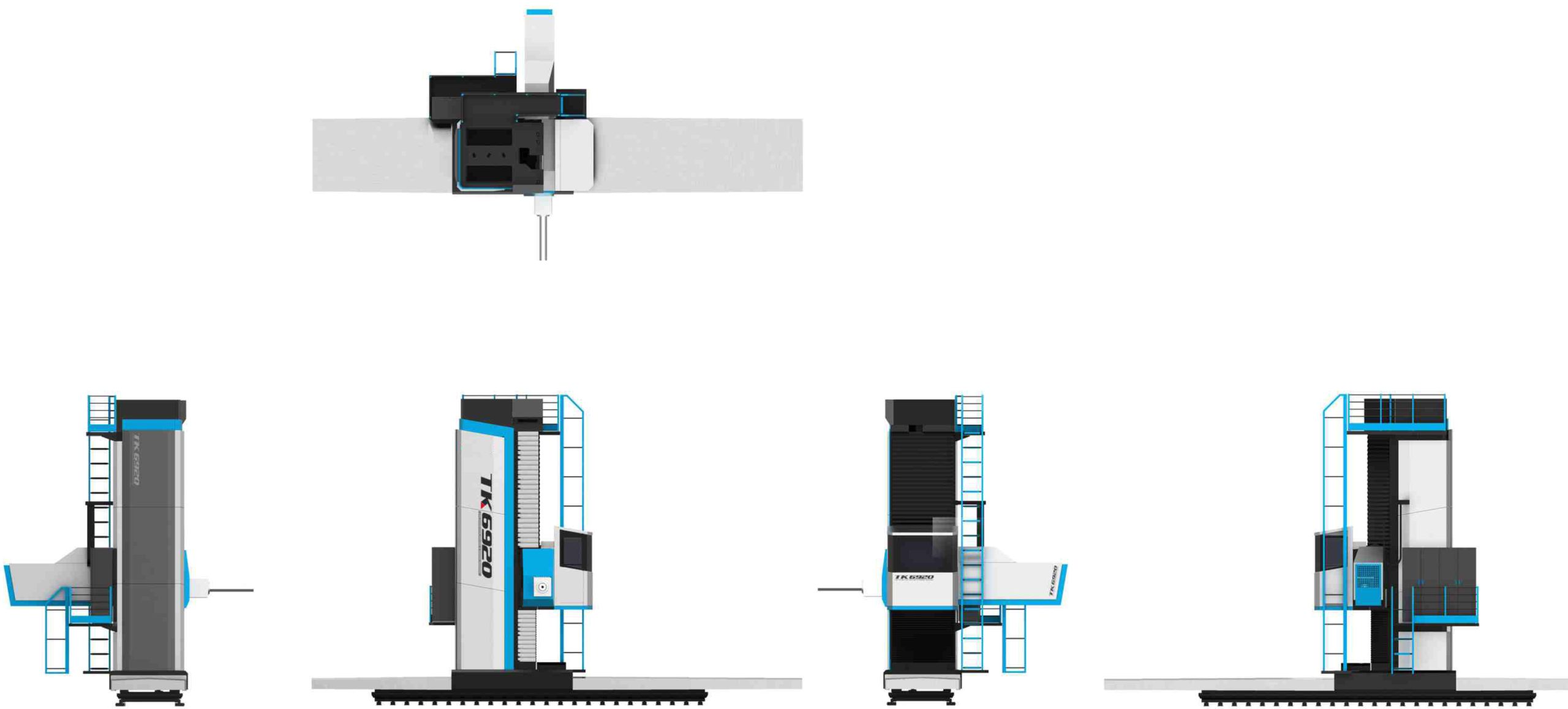

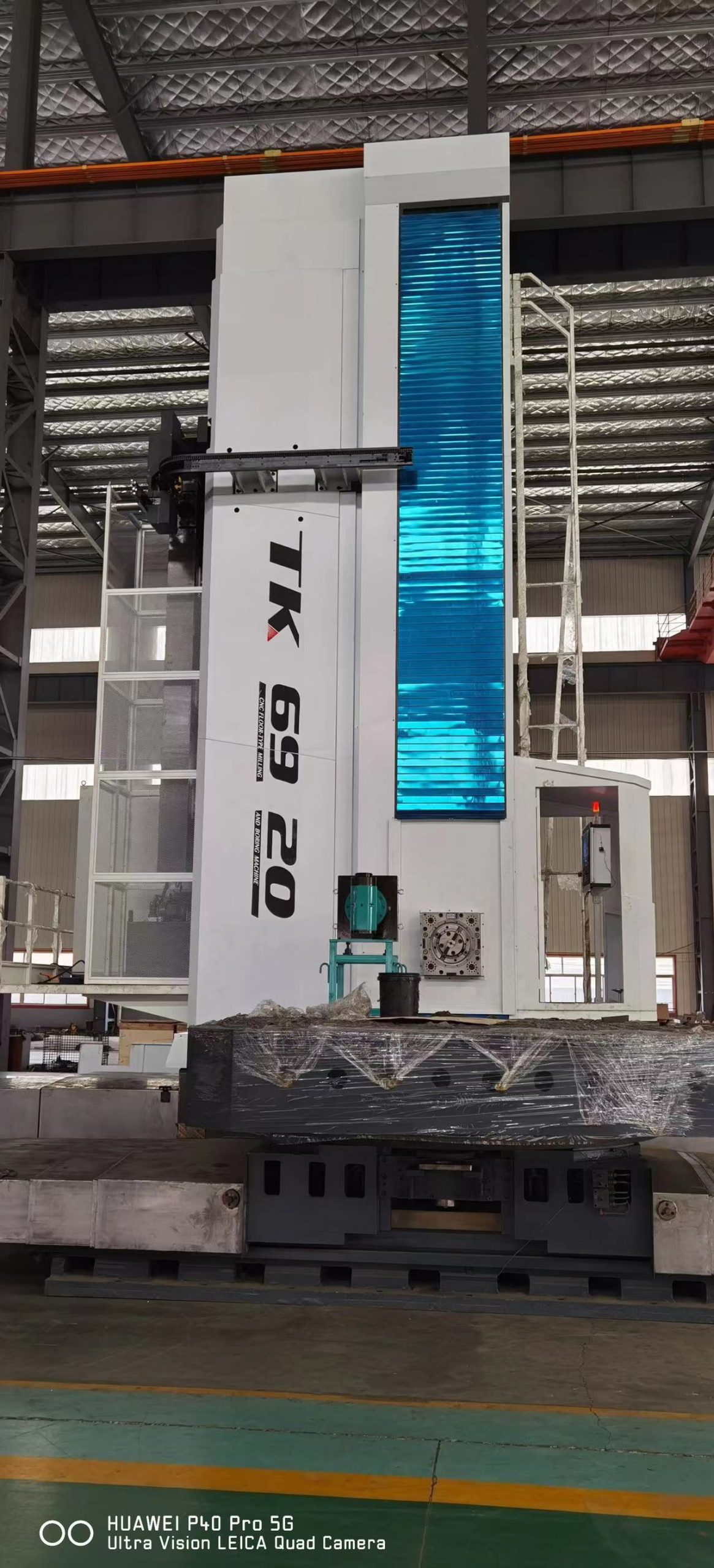

boring head for cnc mill

Floor type

Description

Boring head for cnc mill is a machine equipped with advanced techniques such as mechanics, electrics and hydraulics. Many key techniques are adopted: Hydrostatic guideway (constant flow), No back-lash rack-pinion drive system, ram feed auto compensation, etc.

| No. | Specification | unit | boring head for cnc mill |

| CNC floor type boring machine | |||

| 1 | Spindle diameter | mm | φ260 |

| 2 | Spindle top diameter | mm | φ221.44 |

| 3 | Taper | ISO 50( JT50 7:24 ) | |

| 4 | Blindrivet model | D50 DIN69872 | |

| 5 | Power of main motor | Kw | 85 |

| 6 | Spindle Speed | r/min | 2-800r/min |

| 7 | Max. torque of spindle | N.m | 3136 |

| 8 | Max. axial resistance of spindle | N | 31360 |

| 9 | Worktable size | mm | Optional |

| 10 | Max.loading on table | Kg | 12000 |

| 11 | Worktable transversal travel (X axis) | mm | Optional |

| 12 | Headstock vertical travel(Y axis) | mm | 4000 |

| 13 | Column travel l(Z axis) | mm | 750 |

| 14 | Spindle travel (W axis) | mm | 1250 |

| 16 | Rotary speed of worktable(B axis) | ° | 360 |

| 17 | The width of T-slot and number | mm | 22 |

| 18 | Min .distance from spindle top to table center | mm | 100(spindle extend) |

| 19 | Distance from spindle center to the table | mm | 2375 |

| 20 | Max. Feeding speed (X axis) | mm/min | stepless,1-5600mm/min |

| 21 | Max. Feeding speed (Y axis) | mm/min | stepless,1-5600mm/min |

| 22 | Max. Feeding speed (Z axis) | mm/min | stepless,1-5600mm/min |

| 23 | Max. Feeding speed (V, W axis) | mm/min | stepless,1-5600mm/min |

| 24 | B axis | r/min | 0~1 |

| 25 | System | FANUC OI-MF | |

| 26 | Max. rapid feeding speed (X、Y、Z axis) | mm/min | 6000 |

| 27 | Max .rapid feeding speed(W axis) | mm/min | 3000 |

| 28 | Spindle cooling | 20bar | |

| 29 | Protective door plate | CE Nor |

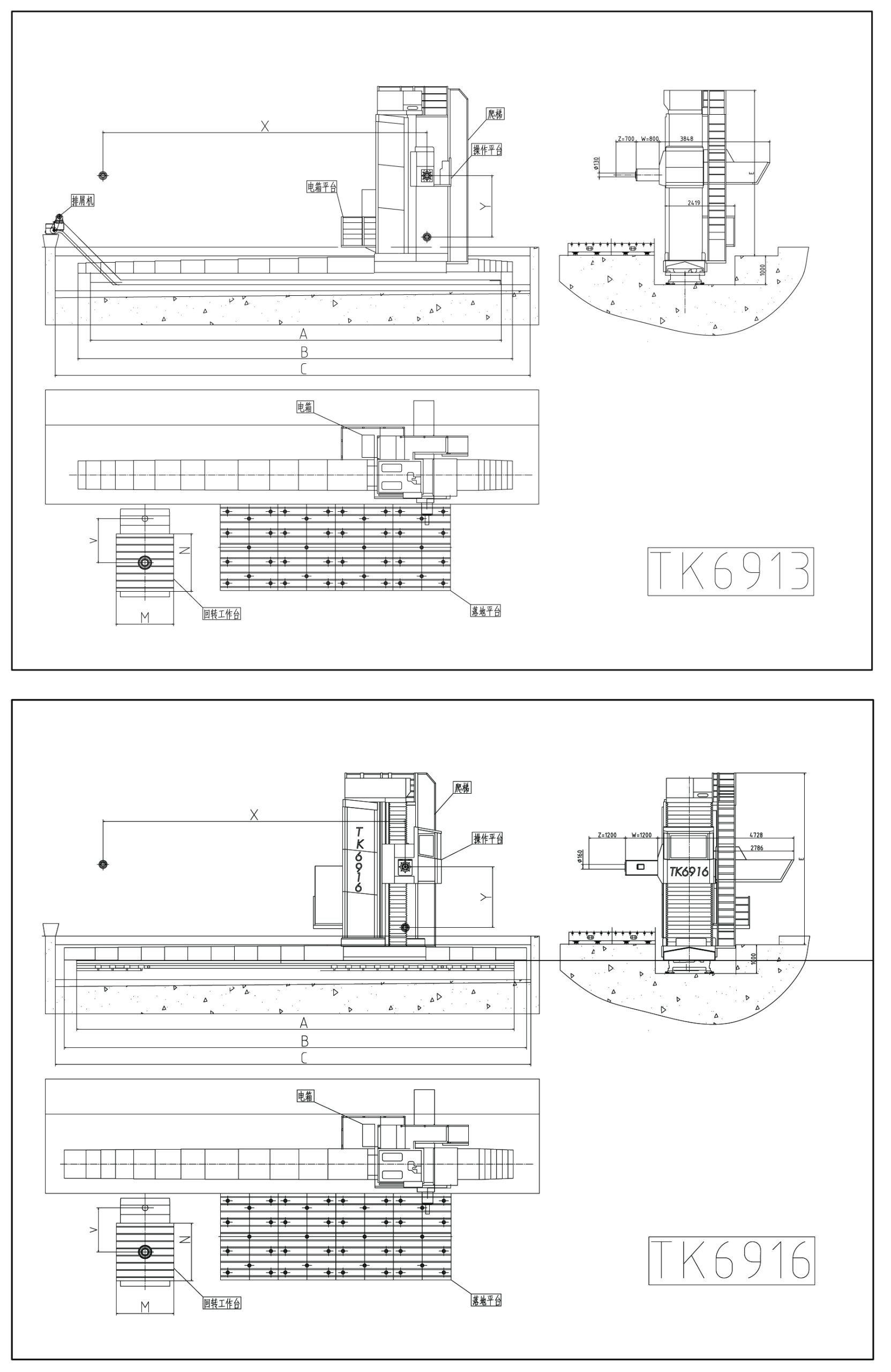

| No. | Item | Unit | Parameter | |

| 1 | Table Size | mm | 2000*2500 | 2500*3000 |

| 2 | Rotary table height | mm | 395 | 395 |

| 3 | Total table height | mm | 1075 | 1075 |

| 4 | Max. load of worktable | ton | 20 | 20 |

| 5 | Longitudinal travel(V axis) | mm | 1400 | 2000 |

| 6 | Indexing range | Degree | 360 | 360 |

| 7 | V axis feedrate | mm/min | 4~3000 | 4~3000 |

| 8 | B axis feedrate | mm/min | 3~3000 | 3~3000 |

| 9 | Indexing accuracy | Degree | 0.005 | 0.005 |

ontrol Axis

Basic configuration of 5 feed axis and one spindle;Each coordinate axis defined as follows:

X axis:Worktable transverse travel

Y axis:Headstock move up and down along the vertical column;

V axis:Worktable longitudinal;

W axis:Ram travel

Z axis: Boring spindle front-back travel;

B axis: NC rotary table rotary indexing

U axis(optional):Facing plate feed

Tags: boring head for cnc mill

What are the boring heads for CNC mill machines and their main functions?

The boring heads for CNC mill is a tool used for expanding or finishing existing holes or boring holes in workpieces.

They have several main functions:

Boring: The main function of the boring head is to expand or adjust the diameter of existing holes.

Precision machining: The boring head is used for precision machining operations to achieve high precision and surface quality within the hole.

Versatility: The boring head is a multifunctional tool that can accommodate various cutting blades or tools, suitable for various apertures and materials.

Depth control: The boring head can accurately control the cutting depth, allowing the operator to obtain the required depth and size very accurately.

Adjustable: Many drill bits are adjustable, allowing the operator to change the cutting diameter within a certain range.

Interchangeability: Boring heads are usually designed to be interchangeable with other tool holders on CNC milling machines.

Complex geometric shapes: By using specialized tools, boring heads can be used to create complex internal geometric shapes, such as conical or contour holes.

How does the design and size of the boring head affect the processing ability and accuracy of CNC mill machines?

The design and size of the boring head can affect the processing ability and accuracy of CNC mill machines in the following ways:

1. Processing ability: The size of the boring head determines the maximum diameter of the hole that can be bored. A larger boring head will have a larger diameter and therefore, the machine will be able to bore larger holes.

2. Accuracy: The design of the boring head is crucial for achieving high levels of accuracy in boring operations. A well-designed boring head will have features such as fine adjustment screws, graduated scales, and a rigid construction, which allow for precise adjustments and positioning of the tool.

3. Rigidity: The size and design of the boring head can also impact the rigidity of the machine. A larger boring head may require a more powerful motor and a sturdier machine structure to handle the increased load.

4. Flexibility: Some boring heads are designed to be modular, allowing for the easy interchangeability of different boring tools and inserts.

You must be logged in to post a review.

Reviews

There are no reviews yet.